Reactor core iterative design system based on Monte Carlo calculation

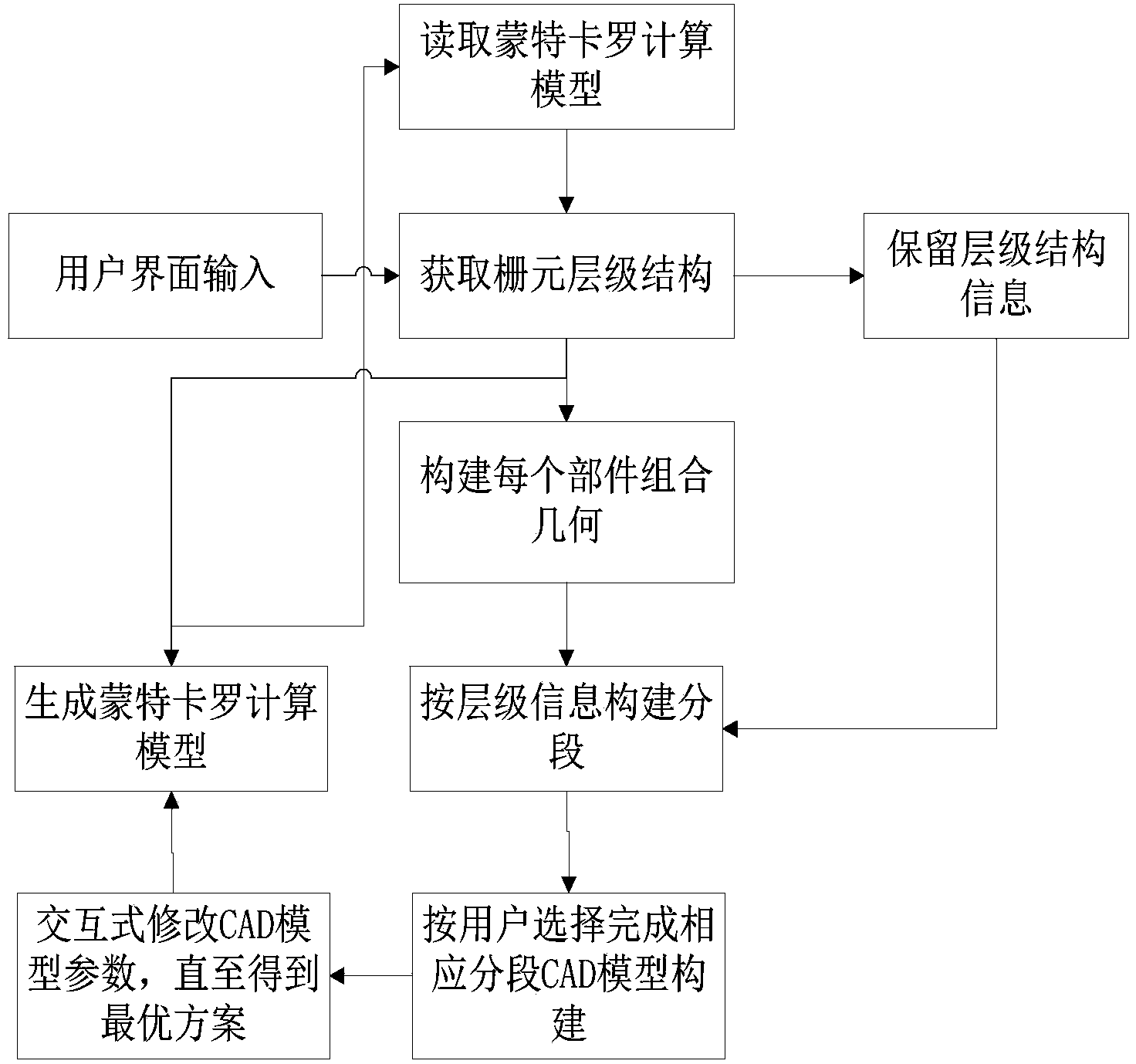

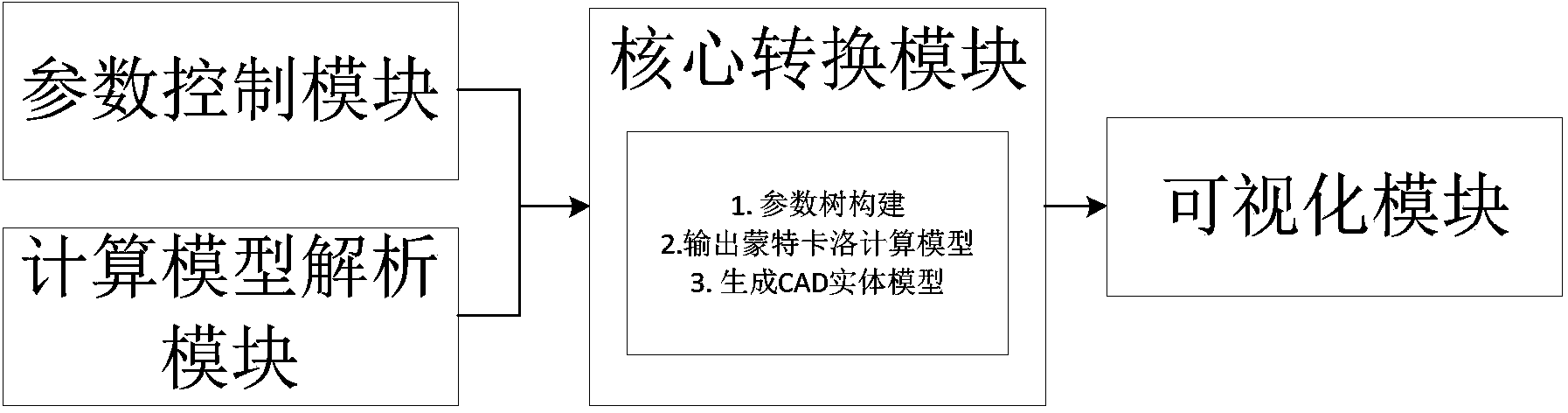

An iterative design and reactor technology, applied in the field of reactor core iterative design system, can solve problems such as the inability to analyze the hierarchical structure of the Monte Carlo calculation model, the inability to complete the iterative modification of the core geometry, and the failure to prove the repeated iterative design of the core, etc., to achieve Improve modeling efficiency, avoid low visualization efficiency, and make the design process clear and clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The goal is to use the present invention to complete the construction of a fast neutron reactor core. The upper and lower grid parameters are shown in Table 1, the fuel rod parameters are shown in Table 2, and other parameters are shown in Table 3. After the modeling is completed, part of the design optimization is carried out.

[0079] Table 1: Upper and lower grid parameters

[0080] Material

S32168

798mm

thickness

5mm

hole diameter

7.9mm

Distance between upper and lower grid plates

400mm

Support hole diameter

41mm

Support hole height

400mm

Support column material

S32168

Distance from support hole to center

325mm

[0081] Table 2: Fuel Rod Parameters

[0082]

[0083] Table 3: Other parameters

[0084]

[0085] The first step is to input the modeling parameters through the interface provided by the system;

[0086] In the second step, click t...

Embodiment 2

[0090] The goal is to parse the original Monte Carlo calculation model file and perform iterative design;

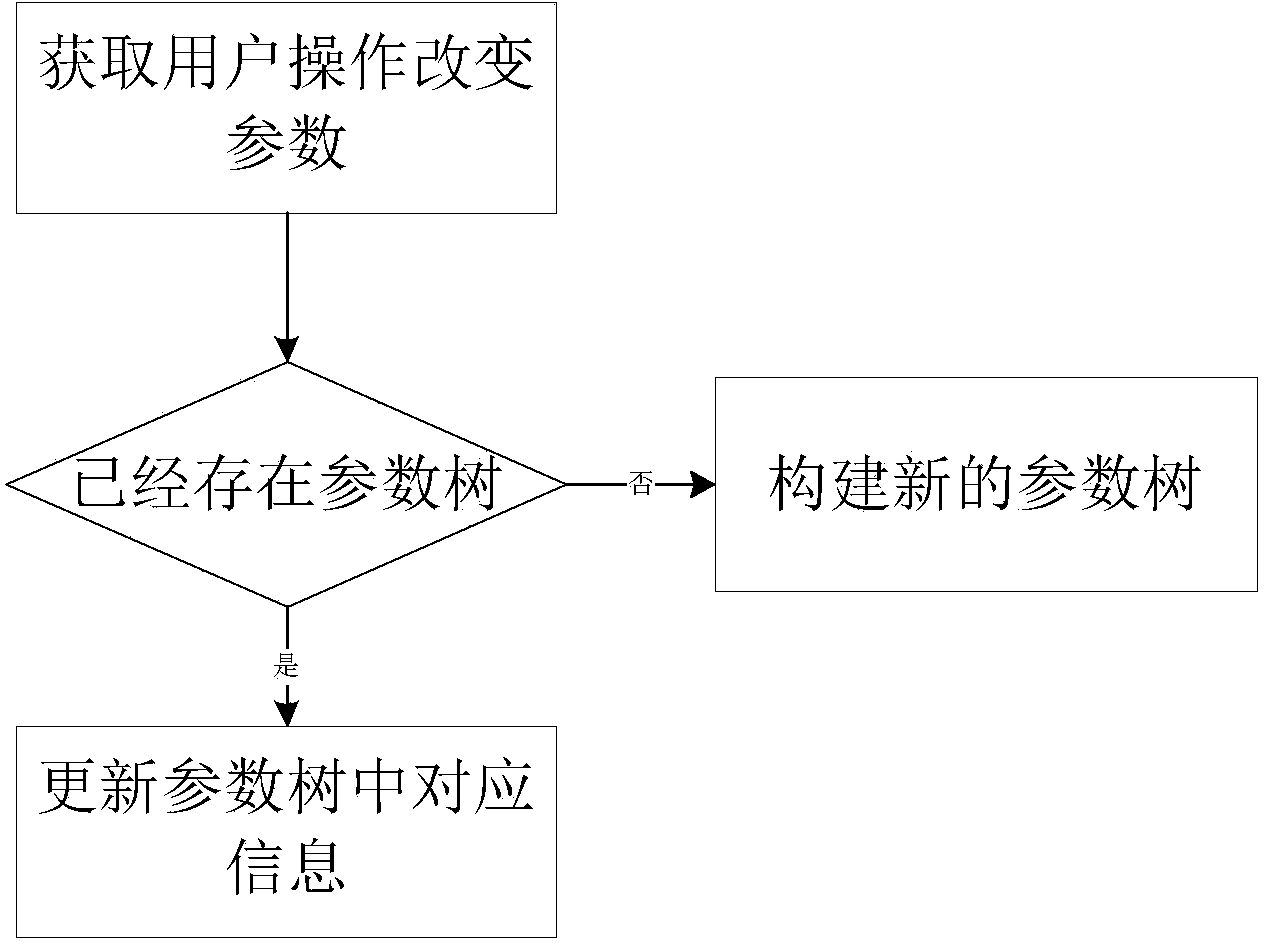

[0091] The first step is to import the MCNP program calculation model file. Figure 12 As shown, it is an existing Monte Carlo calculation model, which can be imported into the calculation model analysis module to complete the construction of the parameter tree.

[0092] The second step is to obtain the CAD engineering model. Such as Figure 13 As shown, it is the core CAD engineering model generated in this embodiment, imported Figure 12 After the Monte Carlo calculation model is shown and the parameter tree is built inside the system, this CAD engineering model is generated;

[0093] The third step is to visually render the CAD engineering model;

[0094] The fourth step is to modify the rendered 3D model through the interface modification function;

[0095] The fifth step is to output the new MCNP program calculation model file.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com