Magnetic latching direct current contactor

A DC contactor and magnetic holding technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of complex assembly process, easy rust of permanent magnets, etc., and achieve short bounce time, simple assembly, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

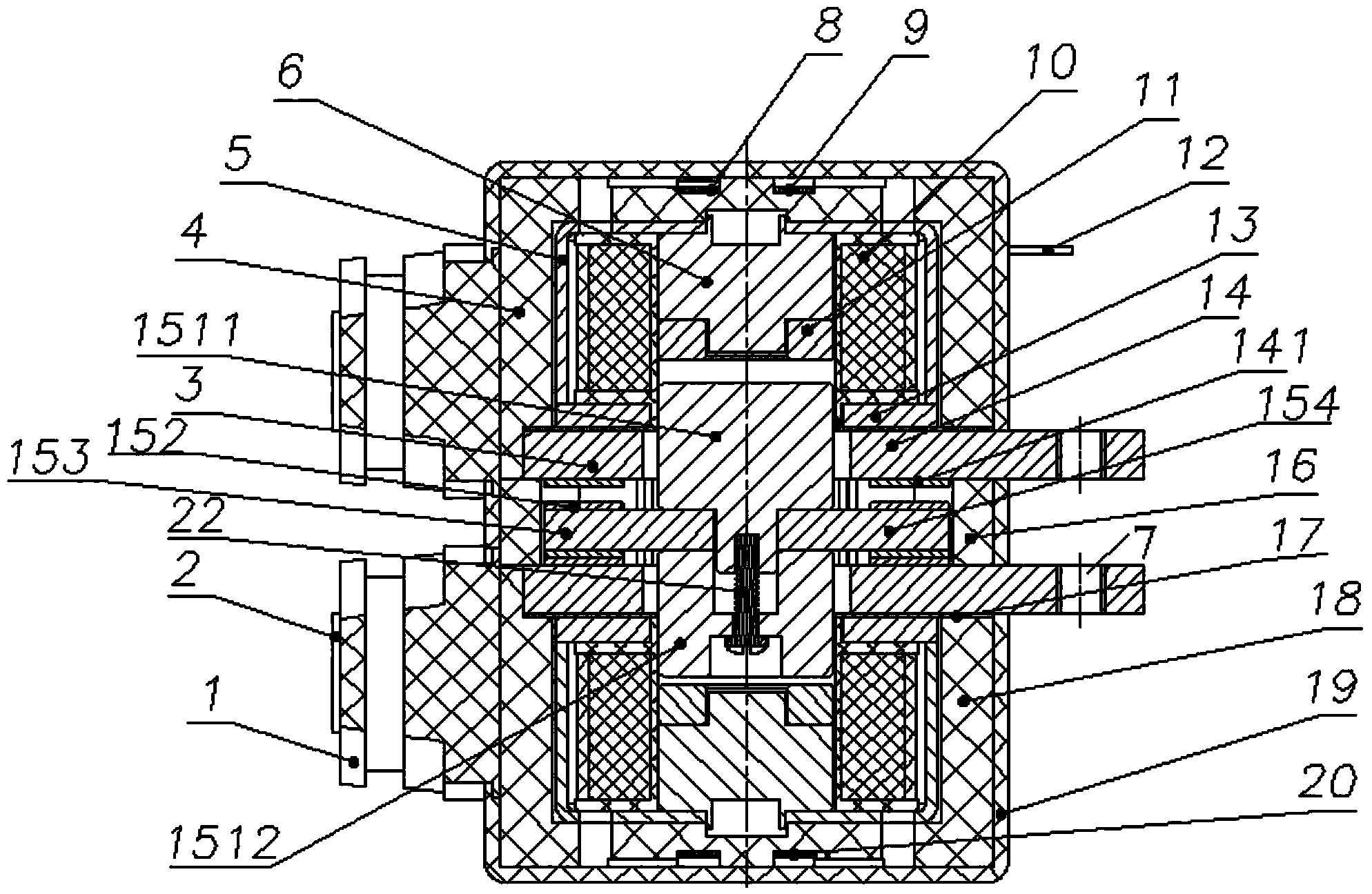

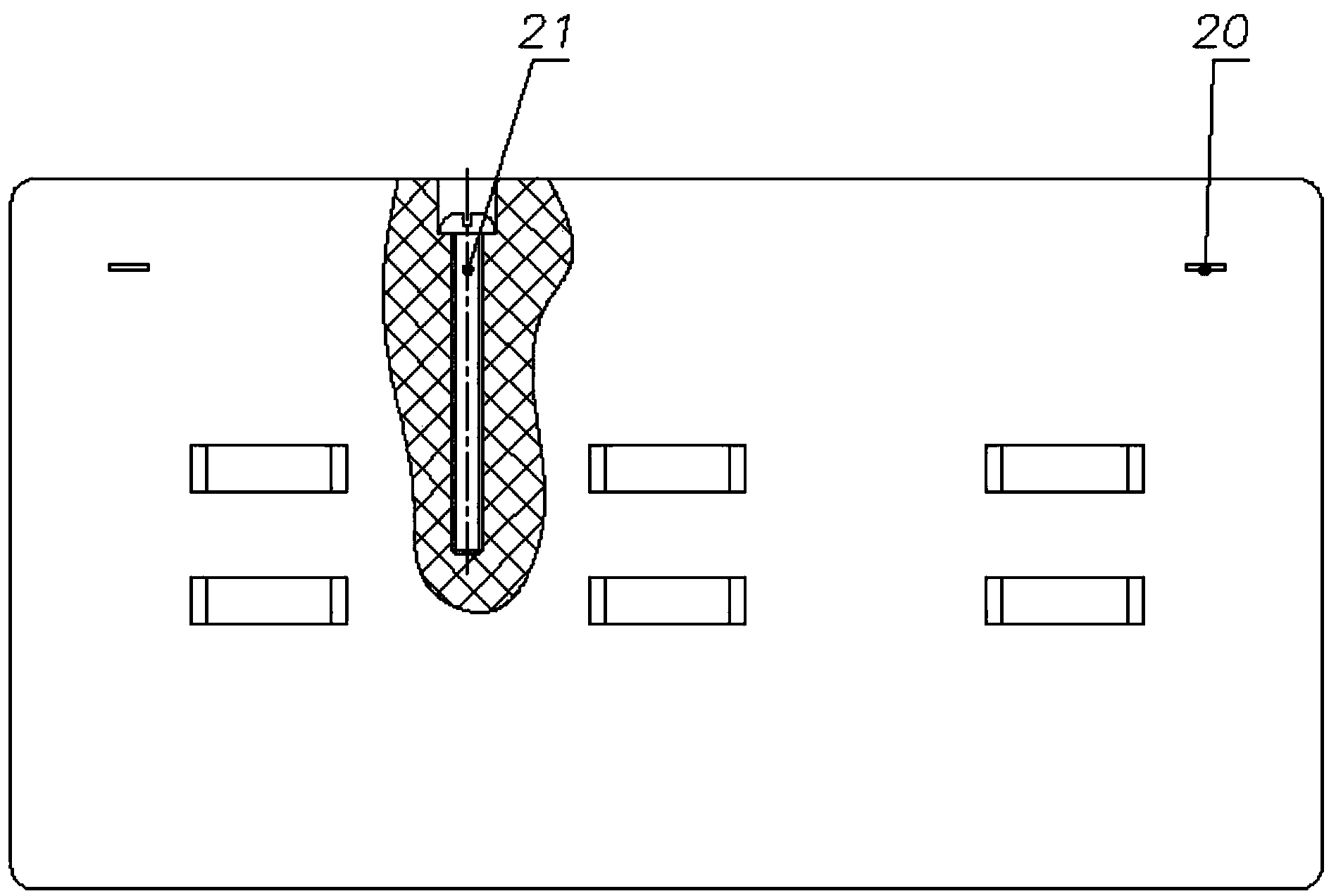

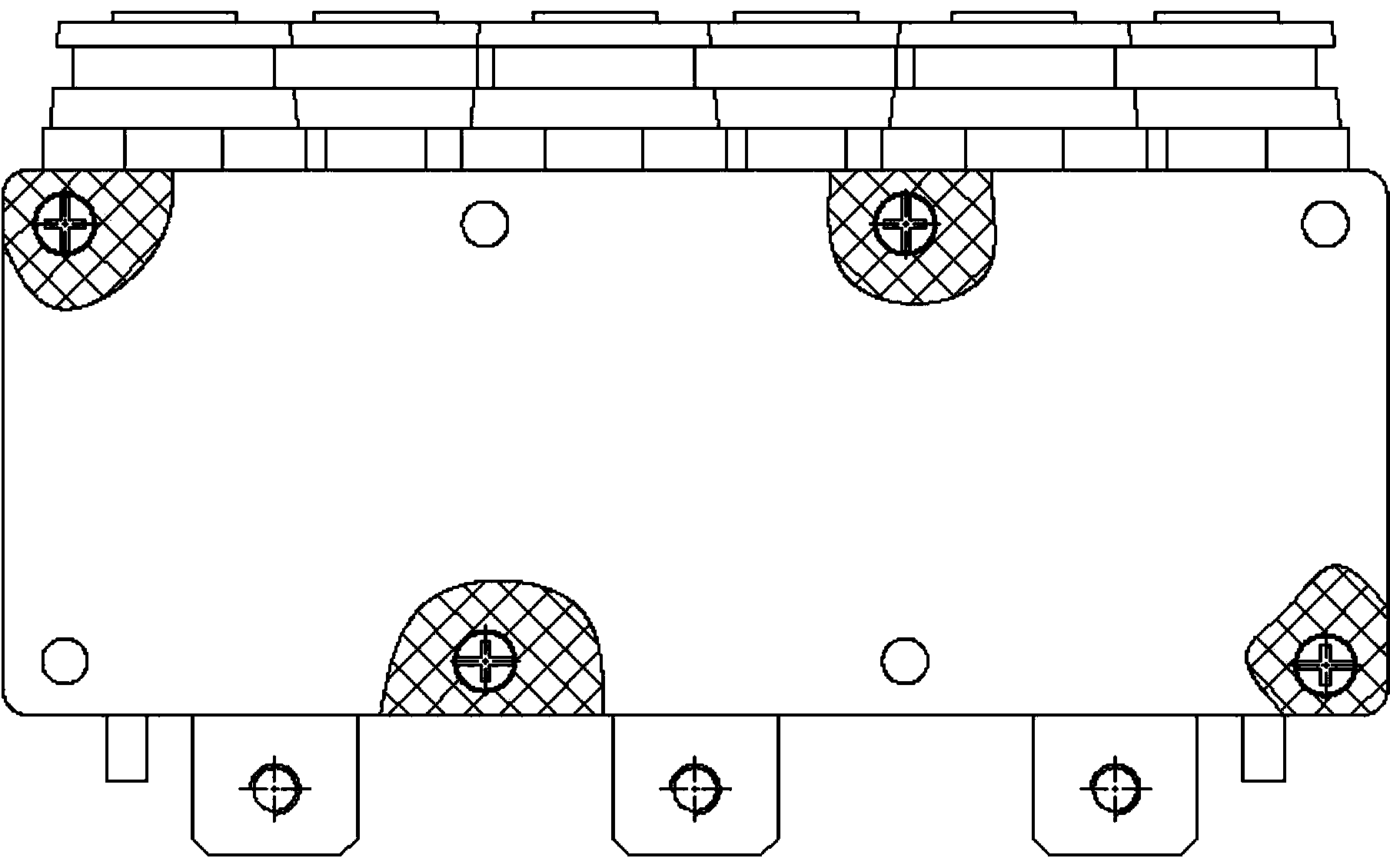

[0029] Such as Figure 1-Figure 3 The shown magnetic holding DC contactor includes a housing, and three sets of contact-electromagnetic units arranged in the housing. The contact-electromagnetic units include a contact system and control the contact system to break. Electromagnetic system for opening and closing.

[0030] In this embodiment, the contact system includes a static contact system and a moving contact system, the static contact system includes two static contact assemblies arranged opposite to each other up and down, the moving contact system includes a moving iron core, and A moving contact assembly that is integrated with the moving iron core. The moving contact assembly is located between the static contact assemblies, and when the moving iron core moves back and forth, the moving contact 152 on the moving contact assembly and the upper side Or the static contact on the static contact assembly on the lower side is connected.

[0031] The electromagnetic system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com