Film forming method for metal blocking layer

A technology of metal barrier layer and film forming method, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of filling barrier layer voids, etc., to reduce barrier layer and substrate voids, simple and efficient process, prevent damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The film forming method of the metal barrier layer of the present invention, the flowchart is as figure 2 As shown, the specific steps include:

[0030] 1) On the silicon wafer (such as the oxide layer 2 of the substrate silicon 1), dry etching is used to etch the through hole 3 (such as image 3 Shown);

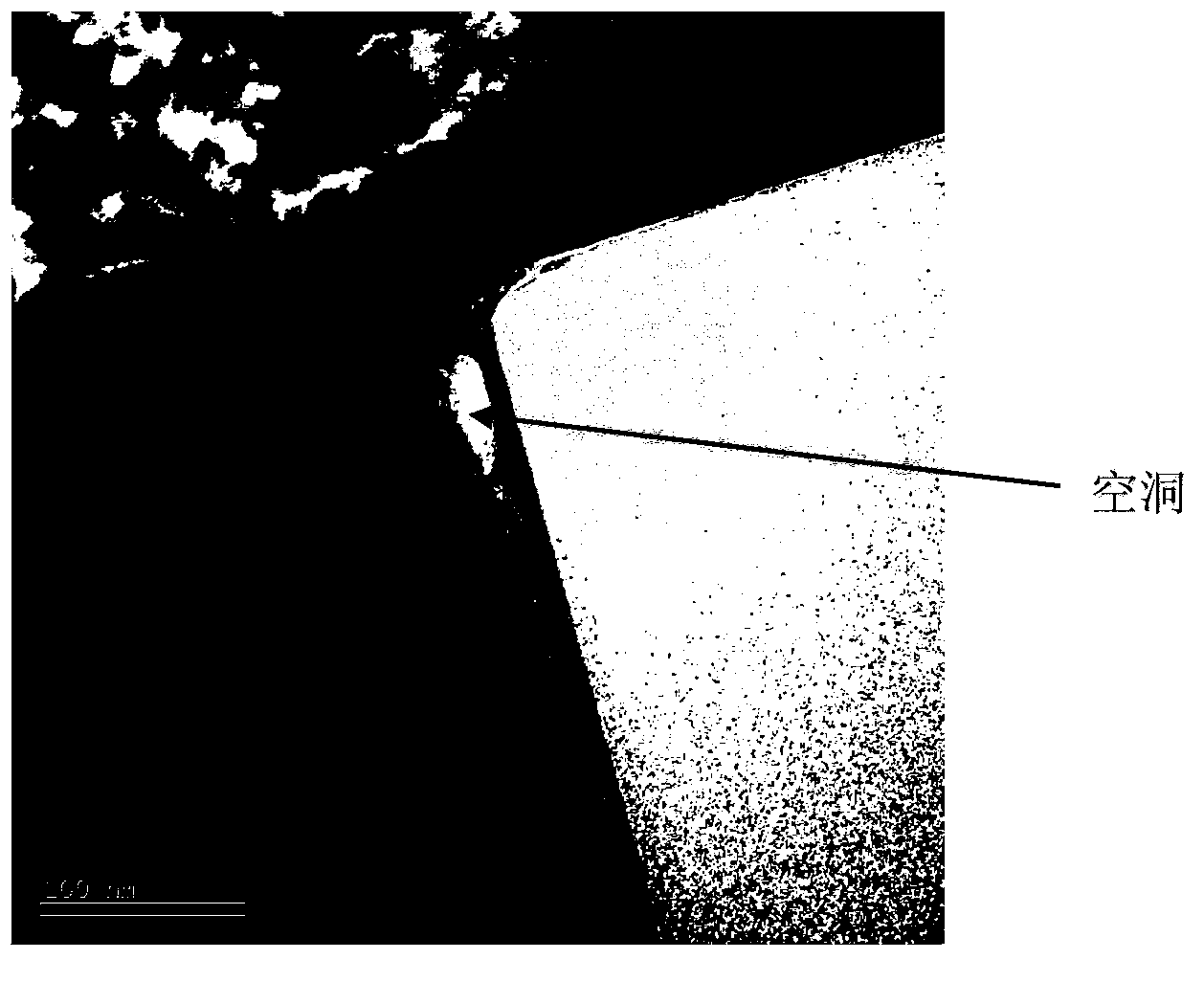

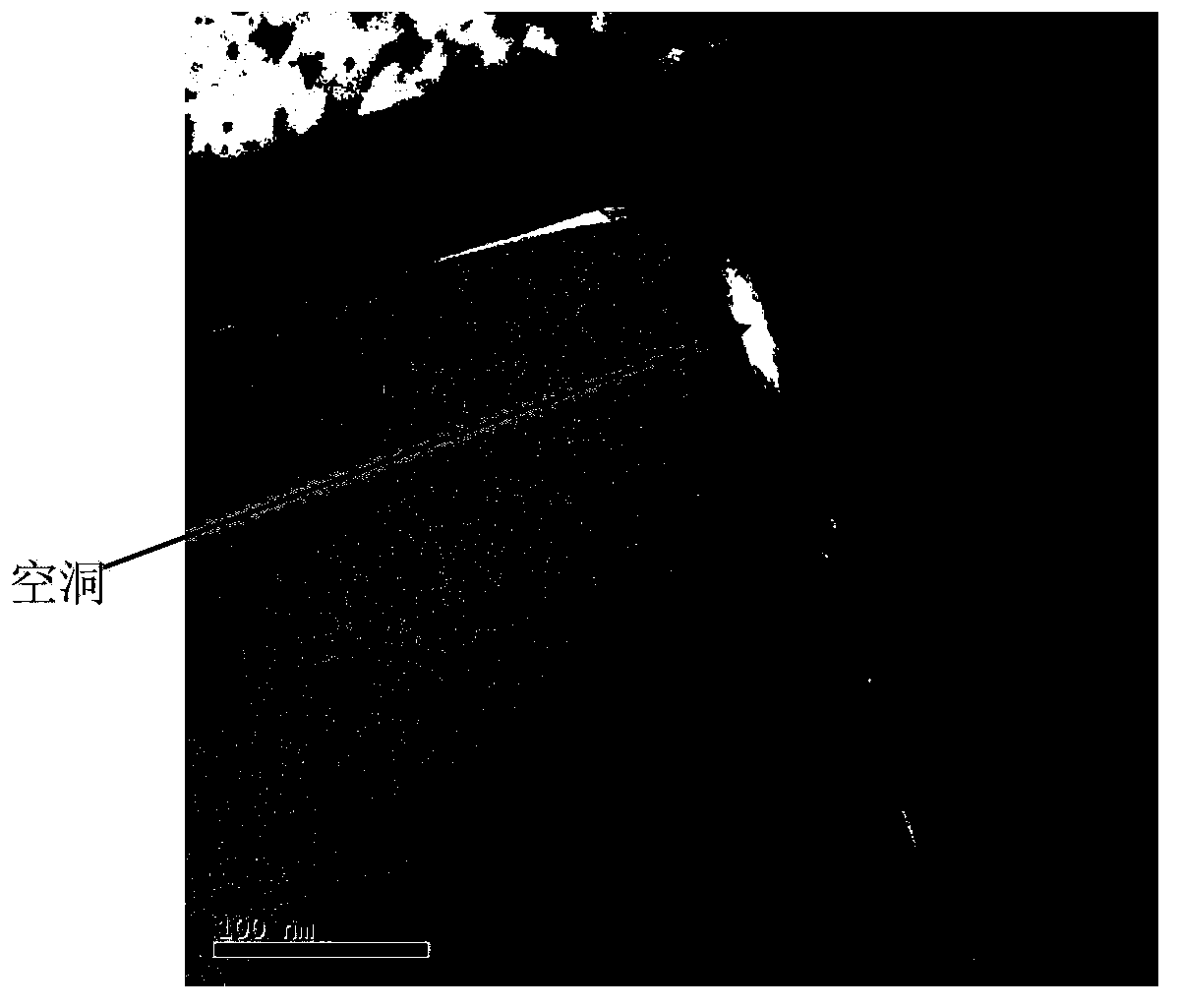

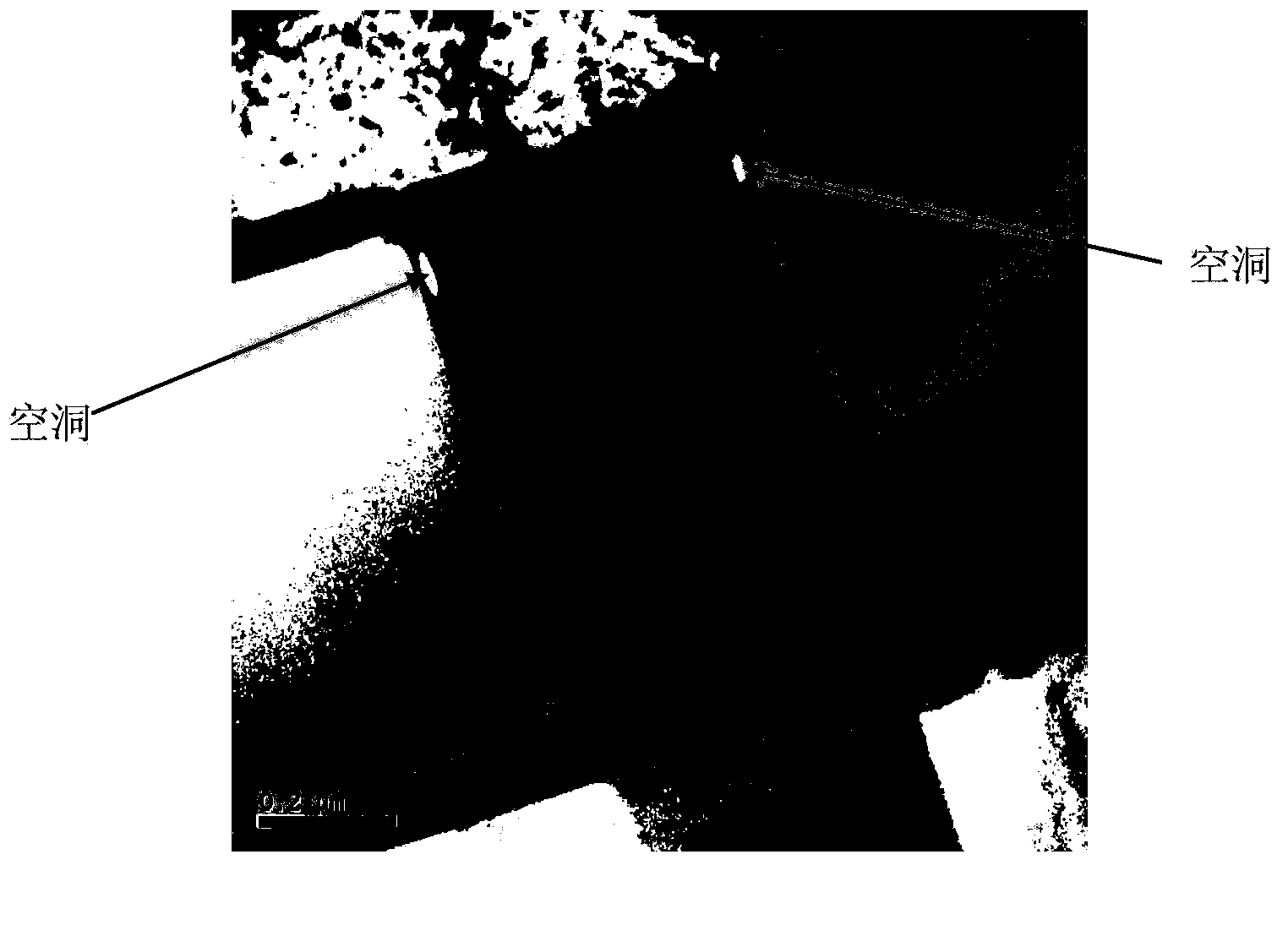

[0031] 2) A first barrier metal layer is formed on the sidewall and bottom of the via 3, where the first barrier metal layer is composed of the Ti layer 4 as the bottom layer and the first TiN layer 5 on the Ti layer 4 (such as Figure 4-5 Shown);

[0032] In addition, the method of forming the first metal barrier layer in this step may be as follows:

[0033] After the Ti layer 4 is formed by a metal physical sputtering method, the first TiN layer 5 is formed by a metal chemical vapor deposition method; wherein the sputtering temperature is 100 to 500° C., and the sputtering pressure is 1 to 10 torr; The deposition temperature is 200~600℃, and the deposition pressure is 1~1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap