Explosion-proof dust sealing device for explosion-proof motor

An explosion-proof motor and sealing device technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of easy to wear skeleton sealing lip, large mechanical loss, energy saving and high efficiency, etc., to improve dustproof efficiency and safety. and long-term, frictional heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate a further understanding of the present invention and make the technical means, technical features and beneficial effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific drawings.

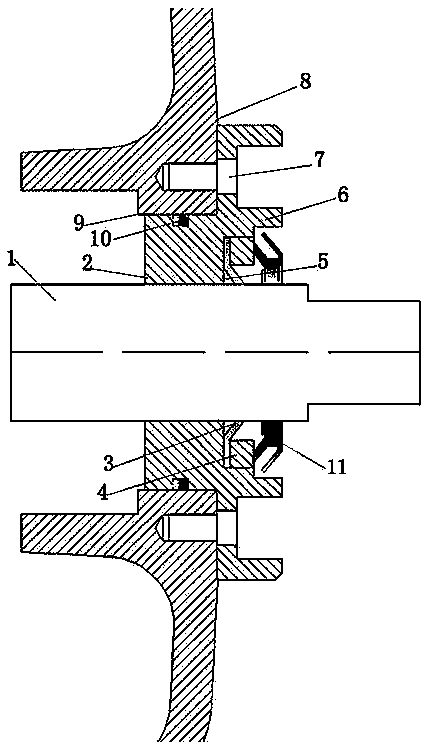

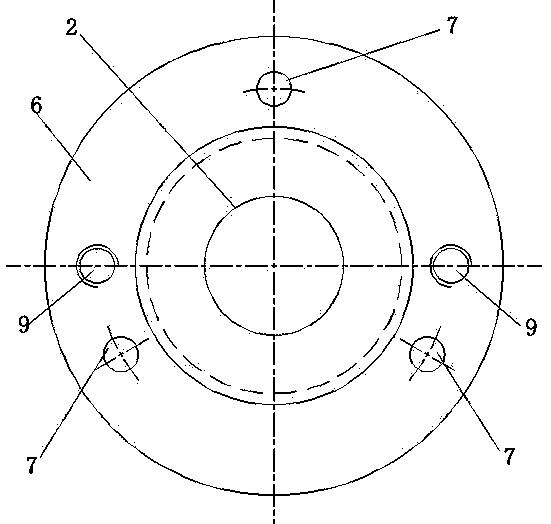

[0018] Such as figure 1 The dust explosion-proof motor explosion-proof sealing device shown is installed on the outer cover of the explosion-proof motor, and its main body is a sealing cover with a circular cross section.

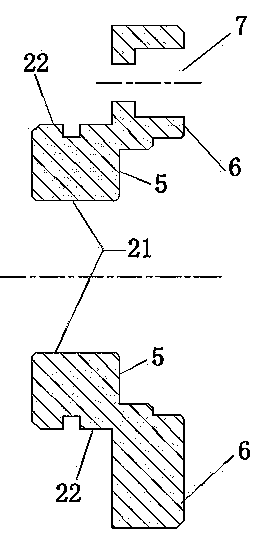

[0019] The structure of the sealing cover is as follows figure 2 and image 3 shown. The first part of the bottom of the sealing cover is the explosion-proof surface (2), which is parallel to the motor shaft (1) during installation, and the surface close to the motor shaft and parallel to the motor shaft is the explosion-proof surface (21) of the motor shaft , the explosion-proof surface close to the inner end surface of the motor outer cover and parallel t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap