Air duct structure of special electronic dehumidifier for electrical equipment

An electrical equipment and dehumidifier technology, applied in the field of air duct structure, can solve the problems of reducing condensation, inability to dehumidify, unreasonable air duct design, etc., so as to reduce ambient temperature rise, reduce condensation surface temperature, and improve safe operation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

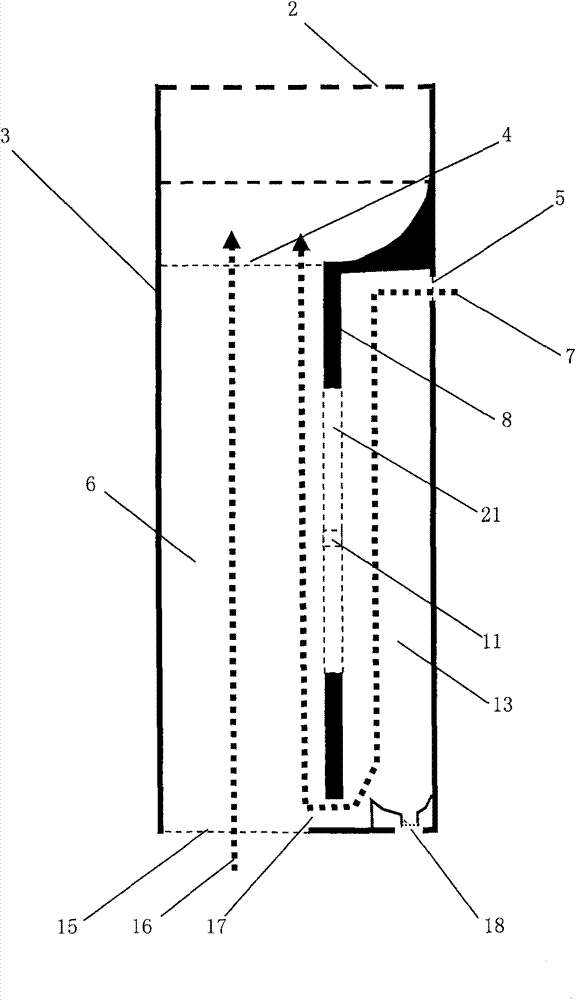

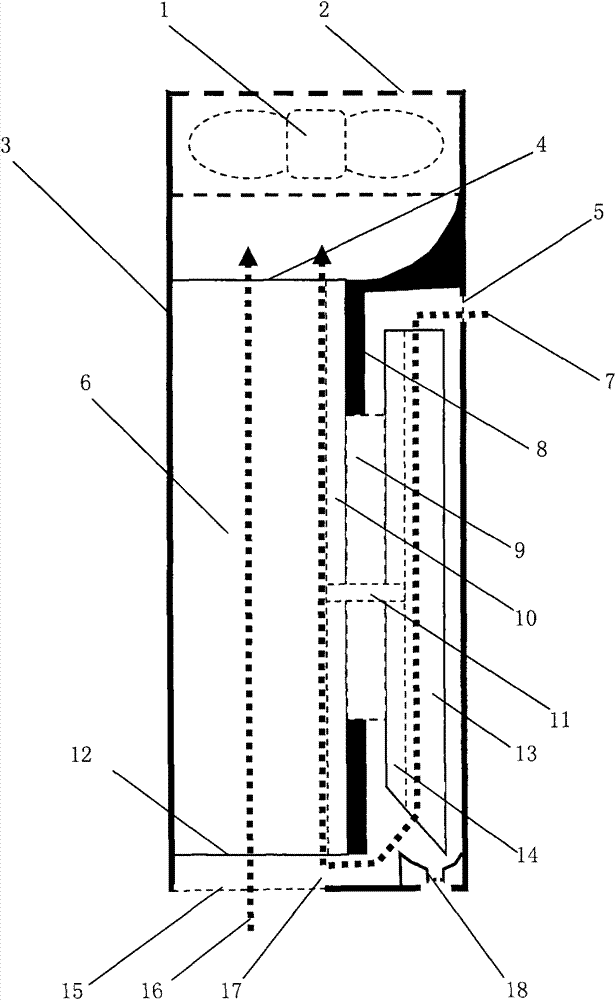

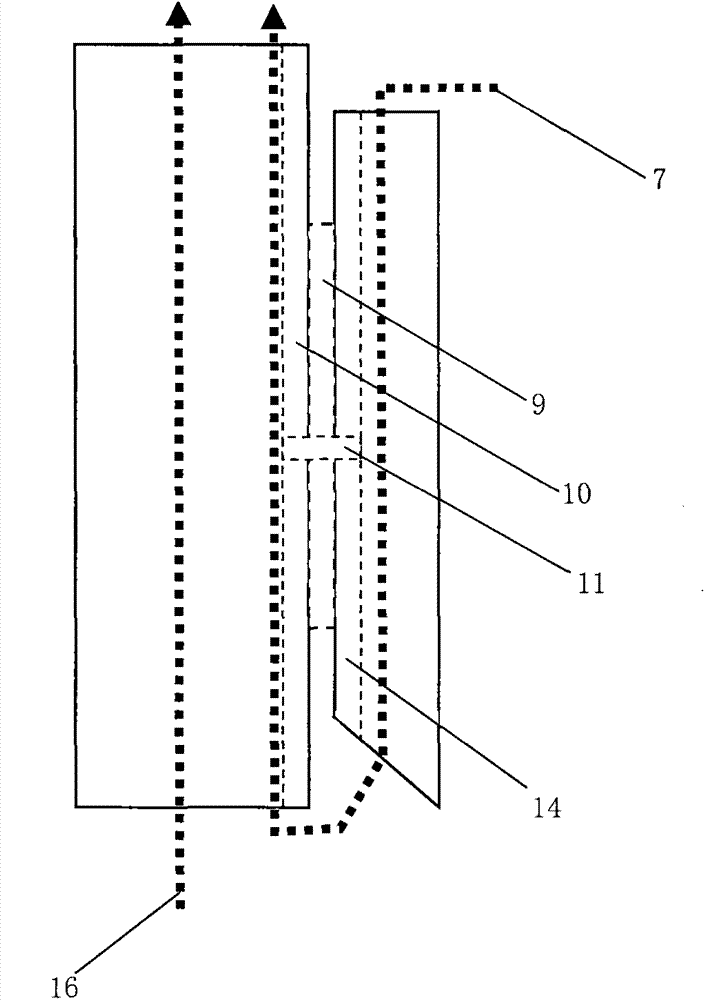

[0013] in figure 1 Shown is the internal air duct structure of the electronic dehumidifier dedicated for electrical equipment. The housing (3) of the dedicated electronic dehumidifier for electrical equipment has a cooling air outlet (2) a cooling air inlet (15) a humid air condensation air inlet ( 5) and the drain outlet of the condensate collection tank (18), the heat dissipation condensing channel is sealed in the housing (3) of the electronic dehumidifier for electrical equipment, and the flame retardant heat insulation board (8) is designed, and the heat dissipation condensate channel is sealed on the flame retardant heat insulation board ( 8) Separate the shell (3) of the electronic dehumidifier for electrical equipment into a heat dissipation channel (6) and a condensation channel (13) which are completely separated at the upper part, and the heat dissipation and condensation channel closes the upper part of the flame-retardant heat insulation board (8) and the electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com