Bar chair stool surface and bar chair comprising same

A bar chair and stool surface technology, applied in the field of bar chairs, can solve the problems of high production cost, many processes, and low production efficiency, and achieve the effects of low manufacturing cost, high structural strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

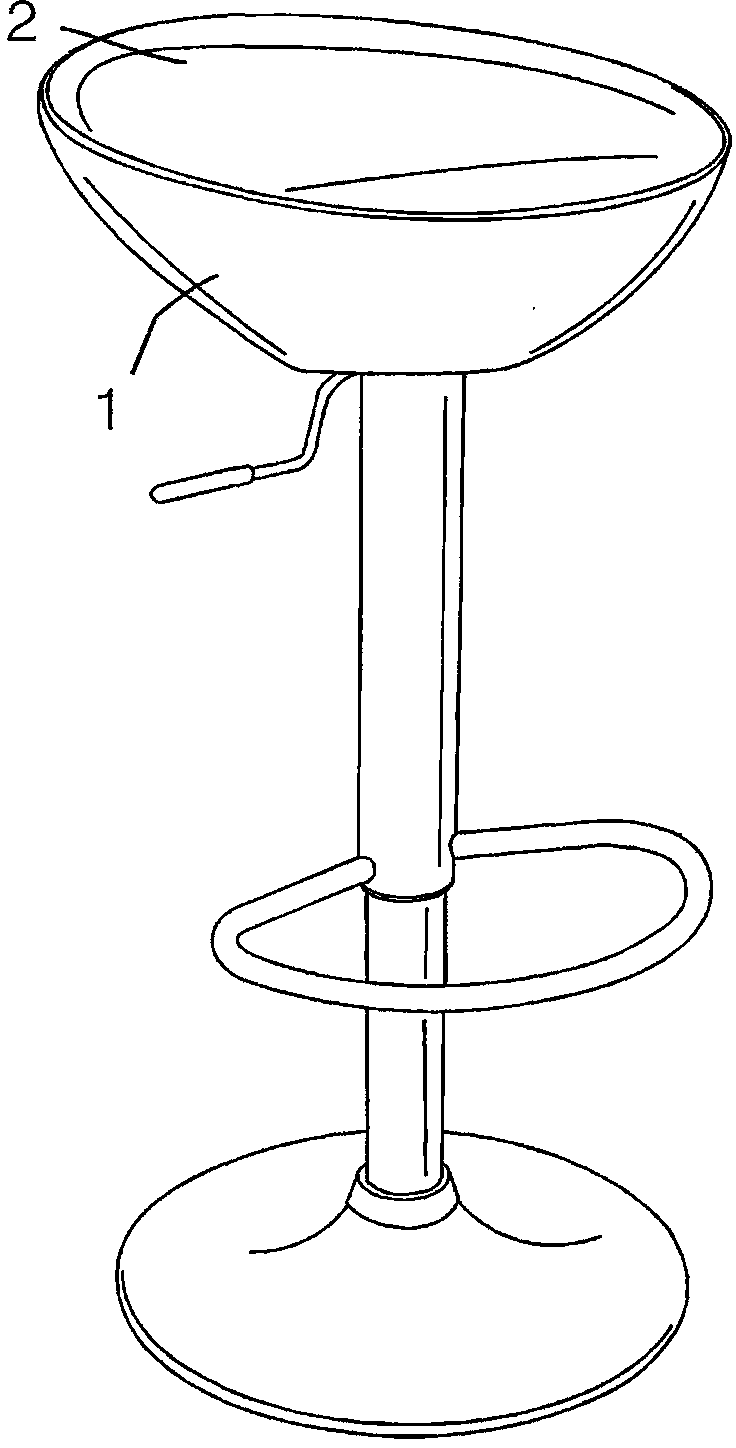

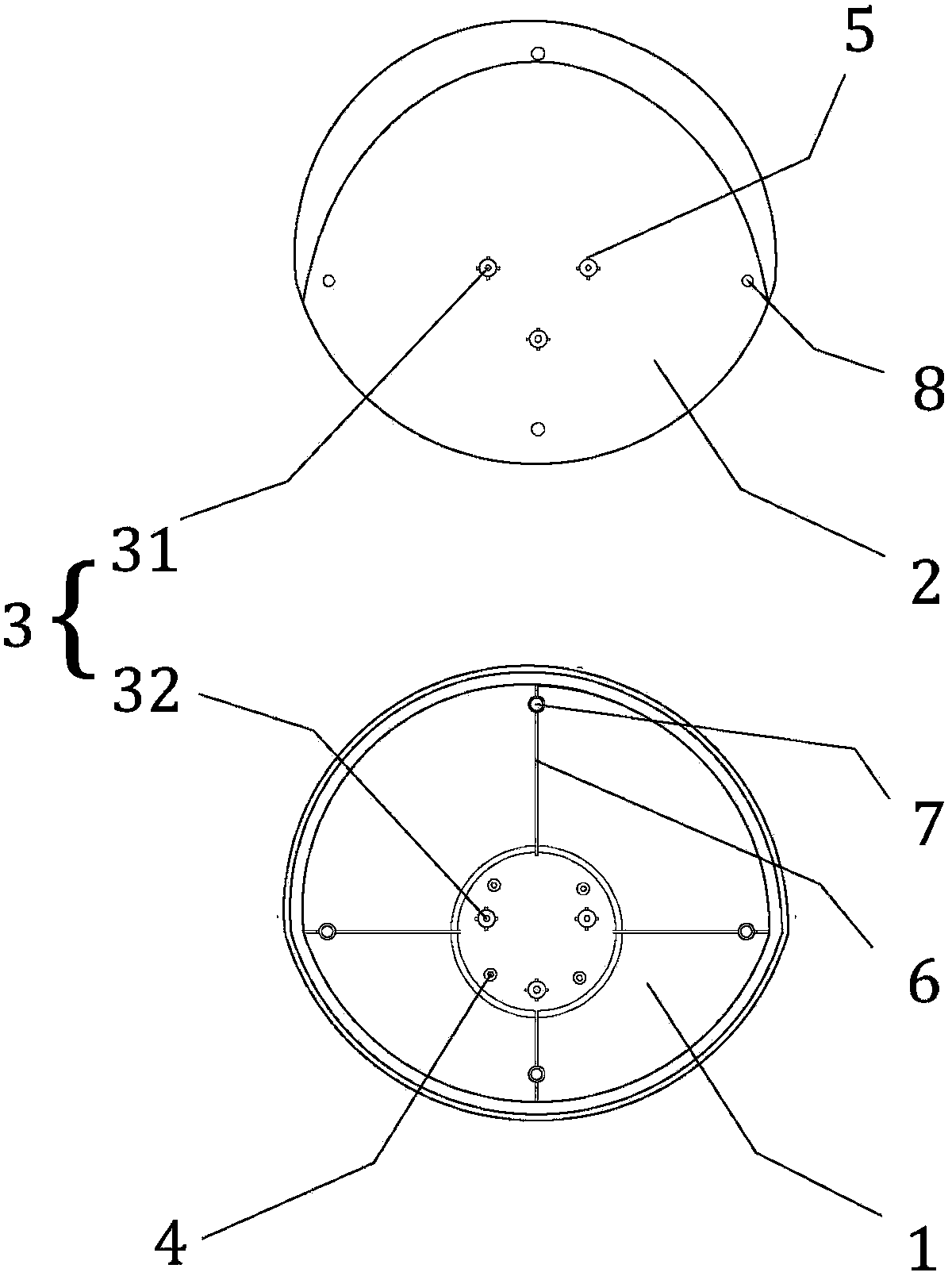

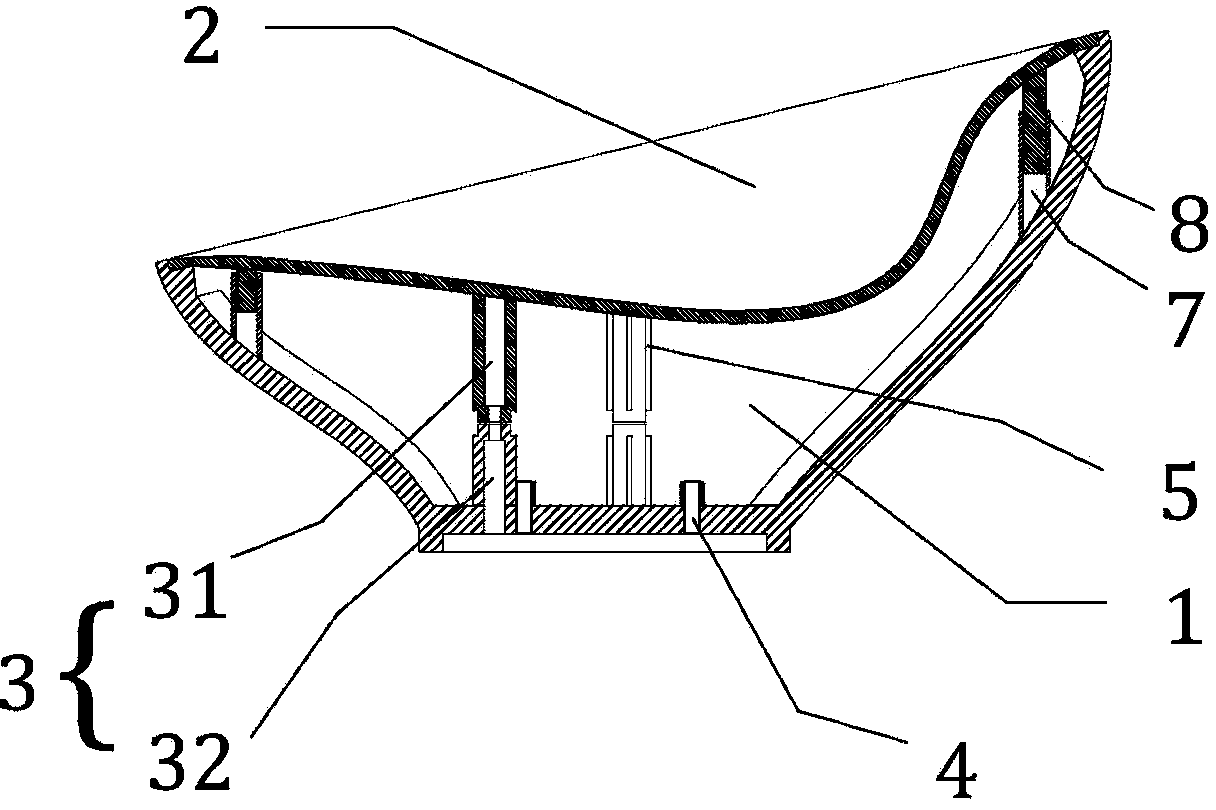

[0026] Such as Figure 1-3 As shown, a stool surface of a bar chair is composed of only a base 1 and a seat plate 2, and a support column 3 for supporting the seat plate 2 is provided between the base 1 and the seat plate 2. The base 1 is provided with a connecting hole 4 for connecting the tray. The support column 3 is composed of an upper half 31 and a lower half 32 , and when the seat plate 2 is joined to the base 1 , the upper half 31 and the lower half 32 are butted. The lower half part 32 is a hollow and upwardly protruding structure; screws are placed in the hollow and upwardly protruding structure, and the screws are screwed into the upper half part 31, so that the upper part The half part 31 is docked with said lower half part 32 . The columnar structures of the upper half part 31 and the lower half part 32 both have a plurality of fins 5 integrally connected with each other for reinforcement. In the inner space formed by the curved contour of the base 1 , a plural...

Embodiment 2

[0028] Such as figure 1 as shown, Figure 2-Figure 3 Available for reference. A stool surface of a bar chair is composed only of a base 1 and a seat plate 2, and a support column for supporting the seat plate 2 is provided between the base 1 and the seat plate 2. The support column is fixedly connected to the base 1, and pads for cushioning the ends of the support column are provided at corresponding positions of the seat plate. In the inner space formed by the curved surface profile of the base 1, a plurality of radial reinforcing ribs integrally connected with the base are provided. In the inner space formed by the curved surface profile of the base 1, a plurality of positioning sleeves are also provided, and at corresponding positions of the seat plate, a plurality of positioning rods matching the positioning sleeves are provided; when the When the seat plate is combined with the base, the positioning sleeve is socketed with the positioning rod.

Embodiment 3

[0030] Such as figure 1 as shown, Figure 2-Figure 3 Available for reference. A stool surface of a bar chair is composed only of a base 1 and a seat plate 2, and a support column for supporting the seat plate 2 is provided between the base 1 and the seat plate 2. The support column is fixedly connected to the seat plate 2 , and pads for cushioning the ends of the support column are provided at corresponding positions of the base 1 . In the inner space formed by the curved contour of the base 1 , a plurality of radial reinforcing ribs integrally connected with the base 1 are provided. In the internal space formed by the curved surface profile of the base 1, a plurality of positioning sleeves are also provided, and at corresponding positions of the seat plate 2, a plurality of positioning rods matching the positioning sleeves are provided; When the seat plate 2 is combined with the base 1, the positioning sleeve is socketed with the positioning rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com