Reaction kettle with rotating shaft with adjustable length

A technology of reaction kettle and rotating shaft, applied in the field of reaction kettle, can solve the problems of insufficient rotating shaft, short falling distance, sufficient material stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

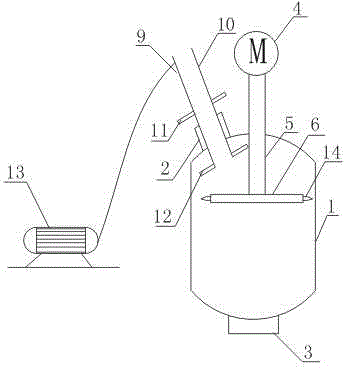

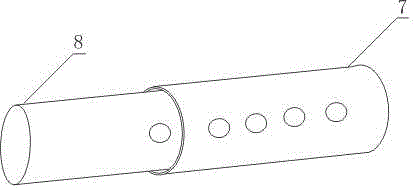

[0017] Such as figure 1 , figure 2 As shown, the reaction kettle with adjustable shaft length includes a kettle body 1, a feed inlet 2 arranged at the upper end of the kettle body 1, and a discharge port 3 arranged at the lower end of the kettle body 1. The kettle body 1 is a cavity structure, It also includes a motor A4 installed on the upper end of the kettle body 1, a rotating shaft 5 connected with the motor A4, the other end of the rotating shaft 5 is inserted into the cavity structure of the kettle body 1, and a rotating piece 6 connected with the rotating shaft 5; The rotating shaft 5 is a telescopic rotating shaft; wherein the rotating shaft 5 includes an outer cylinder 7, an inner cylinder 8 slidingly arranged in the outer cylinder 7, and uniform circular holes are opened on the outer cylinder 7 and the inner cylinder 8, The outer cylinder body 7 and the inner cylinder body 8 are fixed by bolts penetrating the outer cylinder body 7 and the inner cylinder body 8 at t...

Embodiment 2

[0020] On the basis of Embodiment 1, this embodiment also includes an adjustable feeding device 9 installed on the feeding port 2 .

[0021] In this embodiment, the feeding device 9 can adjust the falling distance of the material according to the properties of the material, so as to avoid the phenomenon of material agglomeration due to the short falling distance of the material.

Embodiment 3

[0023] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the feed device 9 includes a feed pipe 10, an upper plate 11 installed on the feed pipe 10, and a lower plate 12 installed at the end of the feed pipe 10. , also includes a motor B13 connected to the feeding device 9 .

[0024] In this embodiment, the feeding pipe 10 can be moved along the axial direction of the feeding port 2 through the control of the motor B13. The setting of the lower plate 12 prevents the feeding pipe 10 from slipping out of the kettle body 1, and the setting of the upper plate 11 avoids Feed pipe 10 is all divided into still body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com