Device for machining multi-start threads

A multi-thread thread and feeding device technology, applied in the field of mechanical processing, can solve the problems of waste of resources, complicated operation, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

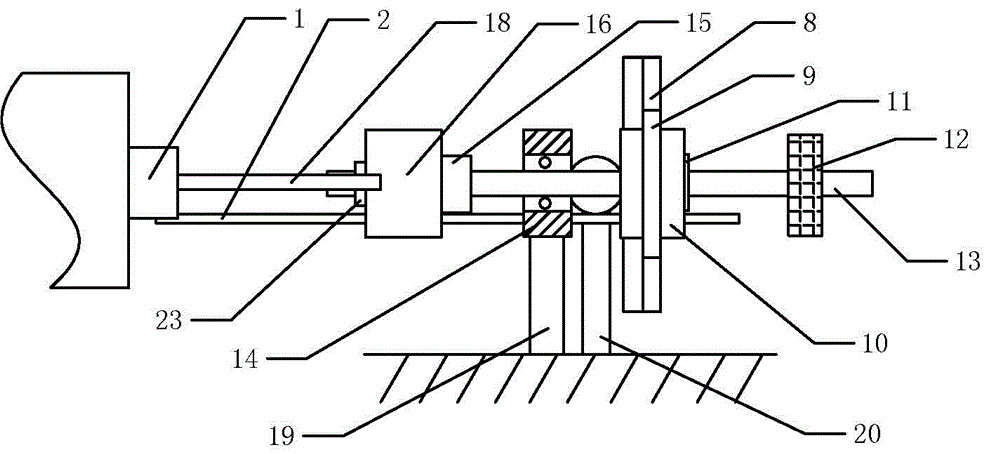

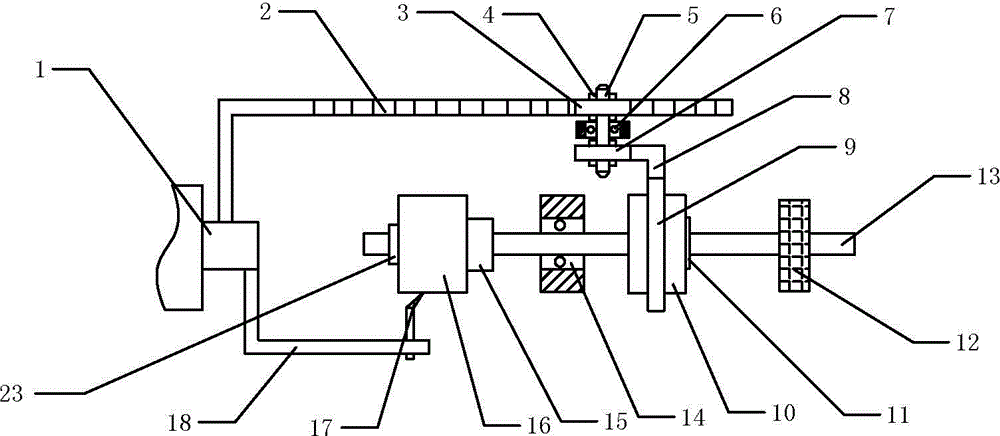

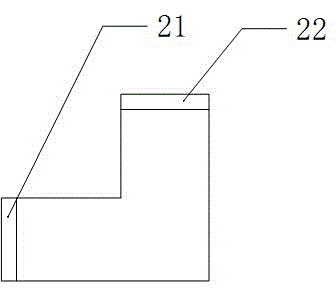

[0021] like figure 1 , figure 2 As shown, the device for processing multi-thread threads of the present invention includes a main shaft 13 sleeved with a tubular workpiece 16. There is a shaft shoulder 15 on the main shaft 13. The tubular workpiece 16 is sleeved on the main shaft 13 and is offset against the shaft shoulder 15. The side away from the shaft shoulder 15 locks the tubular workpiece 16 with a first nut 23; it also includes a rotating device, which includes an active friction plate 11, a sleeve 10, a transverse gear 9, a transverse rack 8, a first vertical Gear 7, the second vertical gear 3, the rotating shaft 5 and the vertical rack 2, the horizontal rack 8 is "L" type, and the two ends of the "L" have horizontal teeth 22 and vertical teeth 21 respectively, the first vertical tooth Both the gear 7 and the second vertical gear 3 are sleeved on the rotating shaft 5, and both ends of the first vertical gear 7 and the second vertical gear 3 are locked with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com