Solar composite package board, component, and preparation process

A packaging board and solar energy technology, which is applied in the field of solar energy applications, can solve the problems of easy color loss and short service life of solar composite packaging boards, and achieve the effects of shortening production time, increasing compatibility and adhesion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

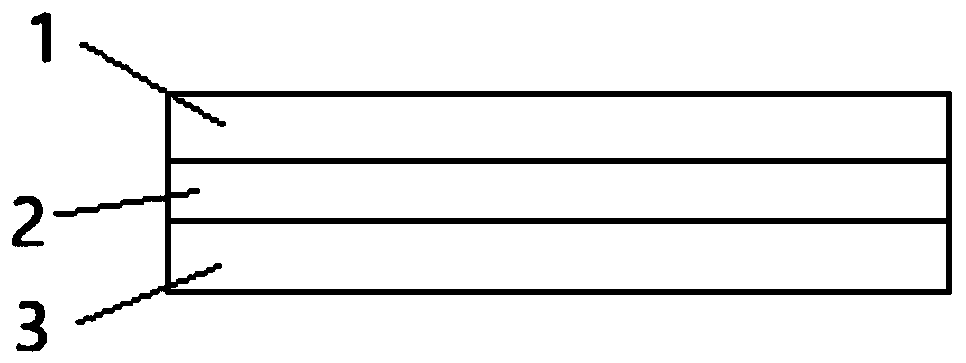

[0039] figure 1 Shown is the solar assembly described in this embodiment, which includes a front panel 1, a back panel 2, and a power generation component 3 arranged between the front panel 1 and the back panel 2, and the back panel 2 is a solar composite package plate.

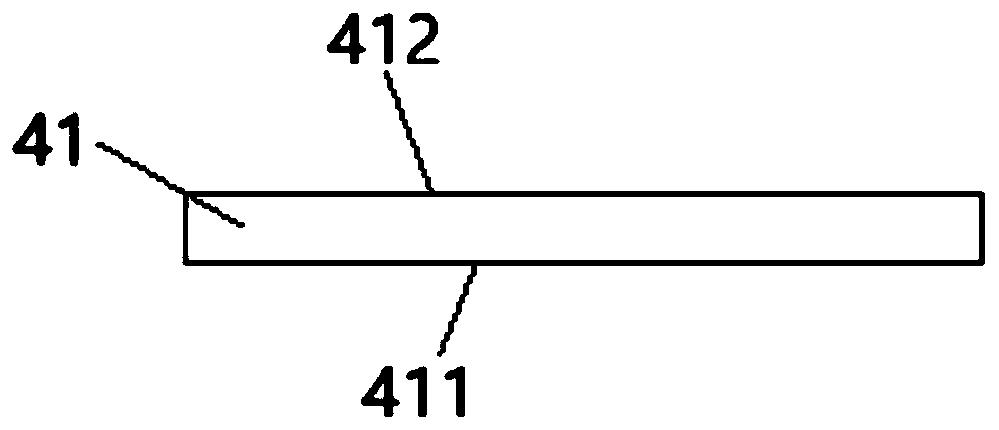

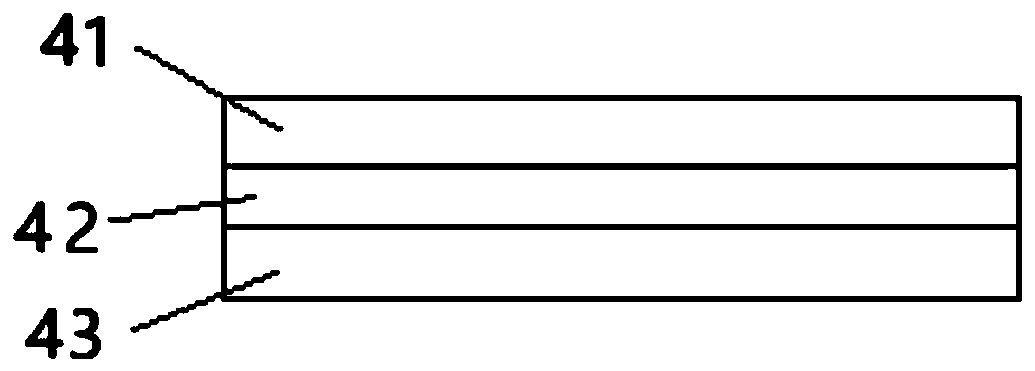

[0040] In this embodiment, the solar composite packaging board includes a light-transmitting substrate layer 41, such as figure 2 As shown, the light-transmitting base material layer 41 has a second surface 412 and a first surface 411 oppositely arranged, and the light-transmitting water vapor barrier layer 42 and the light-transmitting water vapor barrier layer 42 are arranged on the first surface 411. Surfactants are coated on the surface away from the first surface 411 , and a light-transmitting color layer 43 is provided on the surface of the light-transmitting water vapor barrier layer 42 coated with the surfactant.

[0041] Such as image 3 As shown, the surfactant in this embodiment is titanate, th...

Embodiment 2

[0058] This embodiment provides a solar module, which includes a front panel 1, a back panel 2 and a power generation component 3 arranged between the front panel 1 and the back panel 2, the front panel 1 and the back panel 2 It is a solar composite packaging board.

[0059] In this embodiment, the solar composite packaging board includes a light-transmitting base material layer 41, and the light-transmitting base material layer 41 has a second surface 412 and a first surface 411 that are oppositely arranged, and the first surface 411 is provided with There is a light-transmitting water vapor barrier layer 42, and the light-transmitting water vapor barrier layer 42 is coated with a surfactant away from the first surface 411, and the light-transmitting water vapor barrier layer 42 is provided on the surface coated with the surfactant There is a light-transmitting color layer 43, such as Image 6 As shown, the thickness of the transparent color layer 43 is 1 μm. In this embodi...

Embodiment 3

[0065] This embodiment provides a solar component, which includes a front panel 1, a back panel 2, and a power generation component 3 arranged between the front panel 1 and the back panel 2, and the front panel 1 is a solar composite packaging panel.

[0066] In this embodiment, the solar composite packaging board includes a light-transmitting base material layer 41, and the light-transmitting base material layer 41 has a second surface 412 and a first surface 411 that are oppositely arranged, and the first surface 411 is provided with There is a light-transmitting water vapor barrier layer 42, and the light-transmitting water vapor barrier layer 42 is coated with a surfactant away from the first surface 411, and the light-transmitting water vapor barrier layer 42 is provided on the surface coated with the surfactant There is a transparent colored layer 43. In this embodiment, the thickness of the transparent substrate layer 41 is 100 μm; the thickness of the transparent water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com