Flexible tap chuck structure assembly

A tap collet and flexible technology, applied in the field of flexible tap collet structure assembly, can solve the problems of inability to adjust the tapping force, inability to adjust the tapping center, small tap runout, etc., so as to improve the tapping effect and improve the tap life. , The effect of tap beating is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

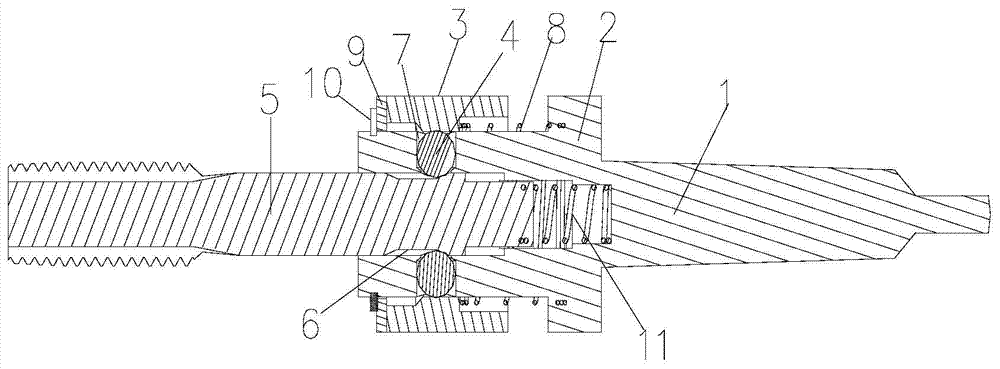

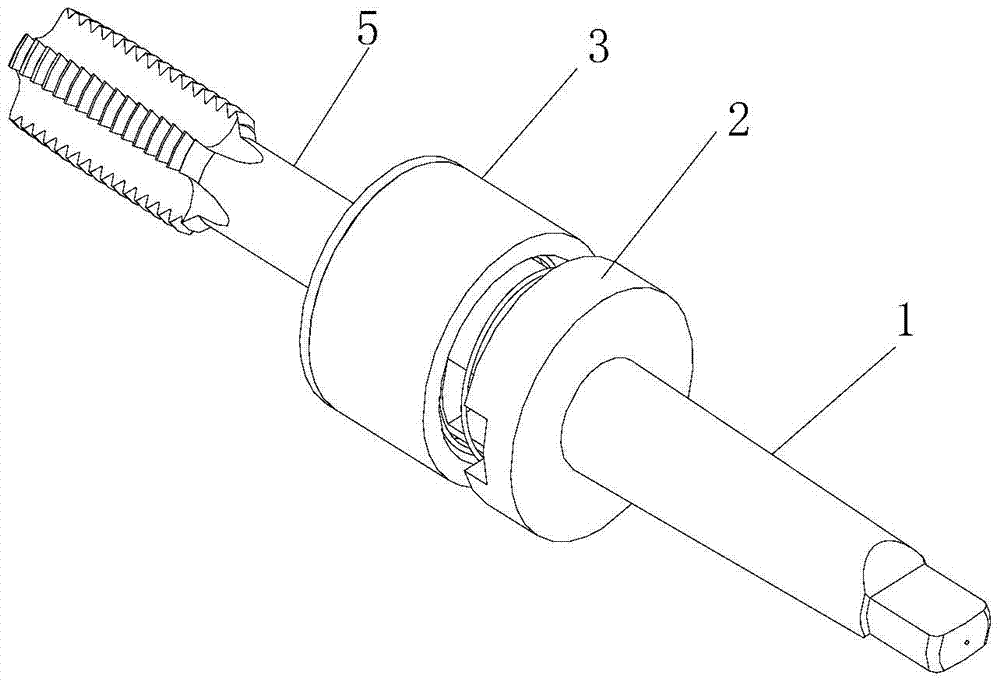

[0018] figure 1 It is a structural schematic diagram of the invention, figure 2 The perspective view of the invention, as shown in the figure: The flexible tap chuck structure assembly of the invention includes a main handle 1, a jacket 2 with a cylindrical clamping body, and a tap 5 that cooperates with the jacket 2. In the jacket 2 A stopper for the tap 5 is arranged on it, and the stopper can move radially and axially along the clamping body. The radial movement of the stopper is used to pull out the tap 5 from the clamping body or fix it after clamping, and the axial movement of the stopper is used to make the tap 5 expand and contract with the advancing spindle when it contacts the workpiece distance.

[0019] In this embodiment, the jacket 2 is provided with an axially deformable elastic member 11; the elastic member can also be arranged at the clamping end of the tap 5 to solve the problem of excessive contact.

[0020] In this embodiment, the stopper includes a tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com