LED (light emitting diode) lamp circuit board welding frame

A technology for LED lamps and circuit boards, applied in the field of welding racks, can solve the problems of easy circuit board shaking, welding errors, etc., and achieve the effects of avoiding unstable fixation, reducing welding errors, and reducing natural temperature recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments, which are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

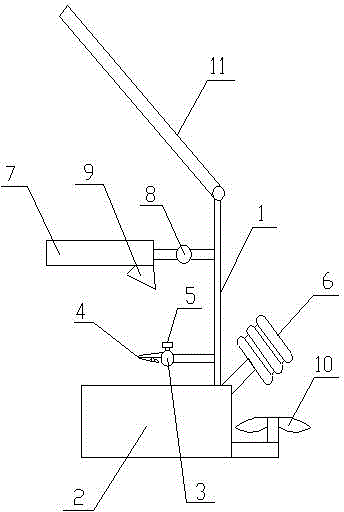

[0012] like figure 1 As shown, this embodiment provides a LED lamp circuit board welding frame, including a main body 1, a base 2 is provided at the bottom of the main body 1, and a circuit board clip is provided at the bottom of the main body 1, and the circuit board clip includes a beam 3 and clip 4, the clip 4 is arranged at both ends of the beam 3, the beam 3 is provided with tightening bolts 5 to control the length of the beam 3 left and right, the lower part of the main body 1 and the side of the circuit board clip are provided with a welding torch The bracket 6 is provided with a magnifying glass 7 on the upper side of the main body 1 . The magnifying glass 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com