Water gap cutting structure of automobile injection mold

An injection mold and nozzle technology, applied in the field of injection molding, can solve problems such as protrusion, incomplete connection of connecting parts, and inability to ensure the stability of injection molding, and achieve the effect of facilitating demoulding and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

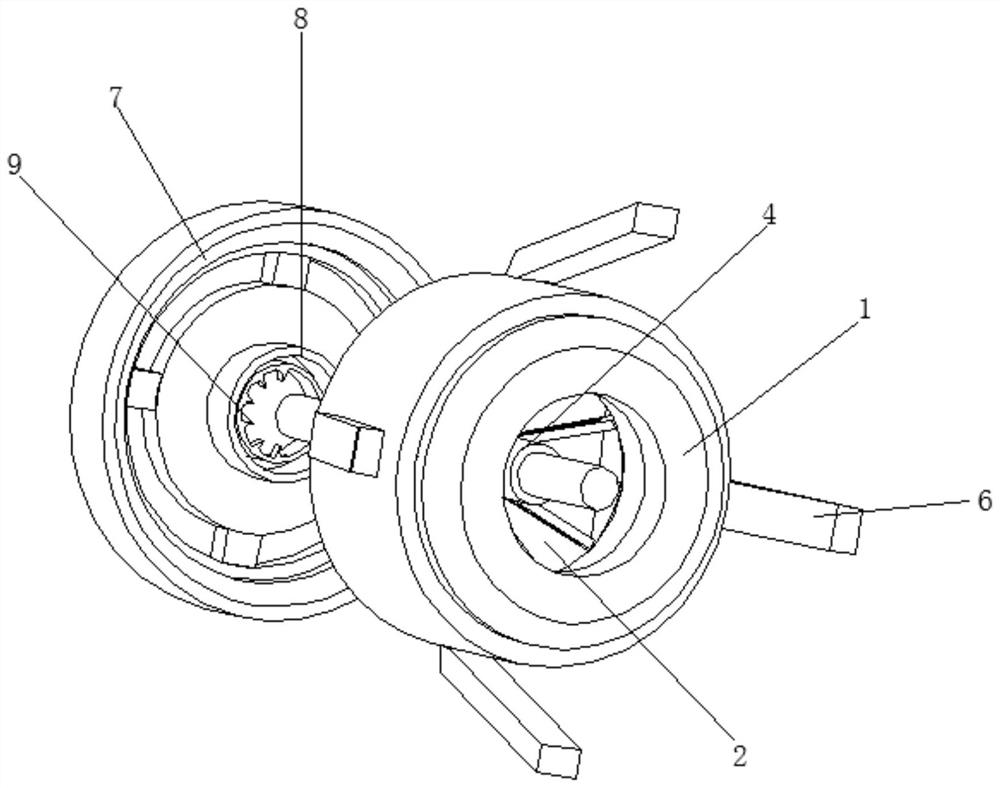

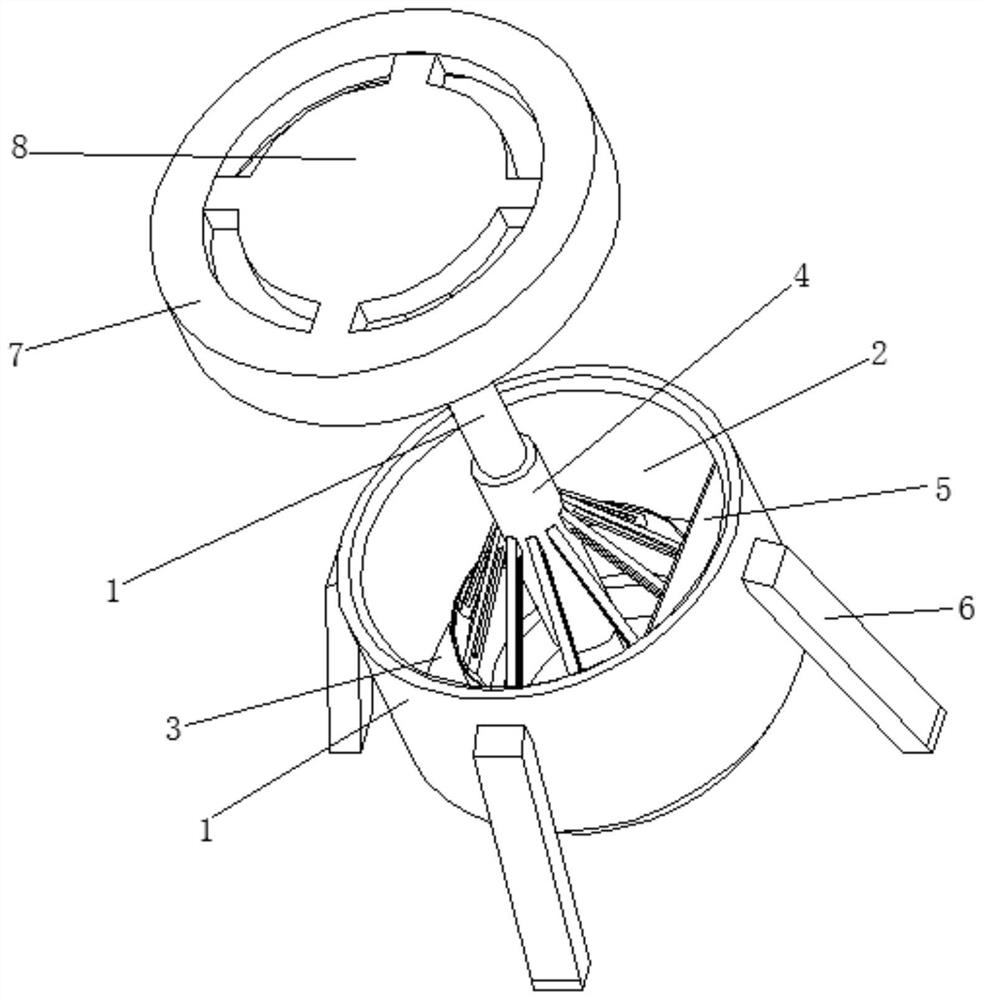

[0033] see Figure 1-2 , the present invention provides a technical solution: a nozzle structure of an automobile injection mold, including a workbench 1, the outer surface of the workbench 1 is provided with a circular through groove 2, and the inner surface of the circular through groove 2 is fixedly connected with a round table 3. The top of the round table 3 is provided with a connecting mechanism 4, the inner surface of the circular through groove 2 is located on the side close to the round table 3 and is fixedly connected with the organic case 5, and the outer surface of the workbench 1 is evenly rotated and connected with supporting legs 6, the supporting legs The inner surface of 6 is provided with a lengthening mechanism 10, the top of the workbench 1 is movably connected with a pressing disk 7, the outer surface of the pressing disk 7 is provided with a connecting groove, and the inner surface of the connecting groove is movably connected with a fixed disk 8 through a...

Embodiment 2

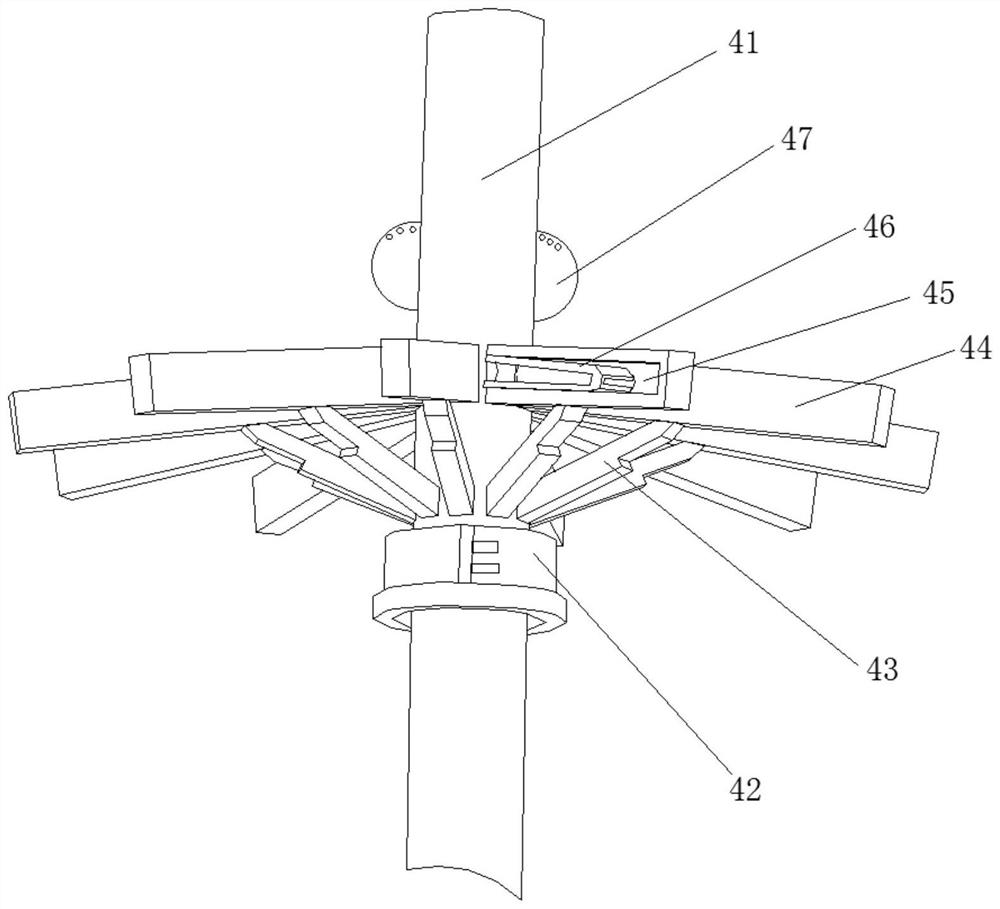

[0037] see Figure 3-5 , the present invention provides a technical solution: the connection mechanism 4 includes a tubular fixed casing 41, the outer surface of the tubular fixed casing 41 is movably connected with the outer surface of the pressing plate 7, and the outer surface of the tubular fixed casing 41 is fixed and located near the working One side of the platform 1 is fixedly connected with a connecting ring 42 , and the outer surface of the connecting ring 42 is movably connected with the outer surface of the tubular fixed casing 41 through buckles. Before the workpiece to be processed is conveyed, the fixed position of the connecting ring 42 can be adjusted, and the support position of the grab bar 44 can be adjusted. When the workpiece is small, it can also be accurately sent to the corresponding processing position. The outer surface of the tubular fixed sleeve 41 The surface is uniformly rotated and connected with a telescopic rod 43, and the top of the telescopi...

Embodiment 3

[0045] see Image 6 , the present invention provides a technical solution:

[0046] The pressing mechanism 9 includes an extrusion box 91, the outer surface of the extrusion box 91 is fixedly connected with the inner surface of the pressing plate 7, the inner surface of the extrusion box 91 is provided with a dark groove 97, and the inner surface of the dark groove 97 is fixedly connected with a The spring sheet 98, the inner surface of the extrusion box 91 is connected with the pressing tool 92 through the rotation of the spring shaft, and the top of the pressing tool 92 is provided with a nozzle groove 93, and the inner surface of the nozzle groove 93 is movable with the outer surface of the tubular fixed casing 41. Connection, the outer surface of the pressing tool 92 is fixedly connected with the fan piece 94, the outer surface of the fan piece 94 is uniformly fixedly connected with the connecting piece, and the outer surface of the connecting piece is movably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com