An online running-in platform

A header and corn technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of insufficient running-in of corn harvester header 10, difficulty in running-in power input, difficulty in ensuring the factory quality of corn harvester header 10, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

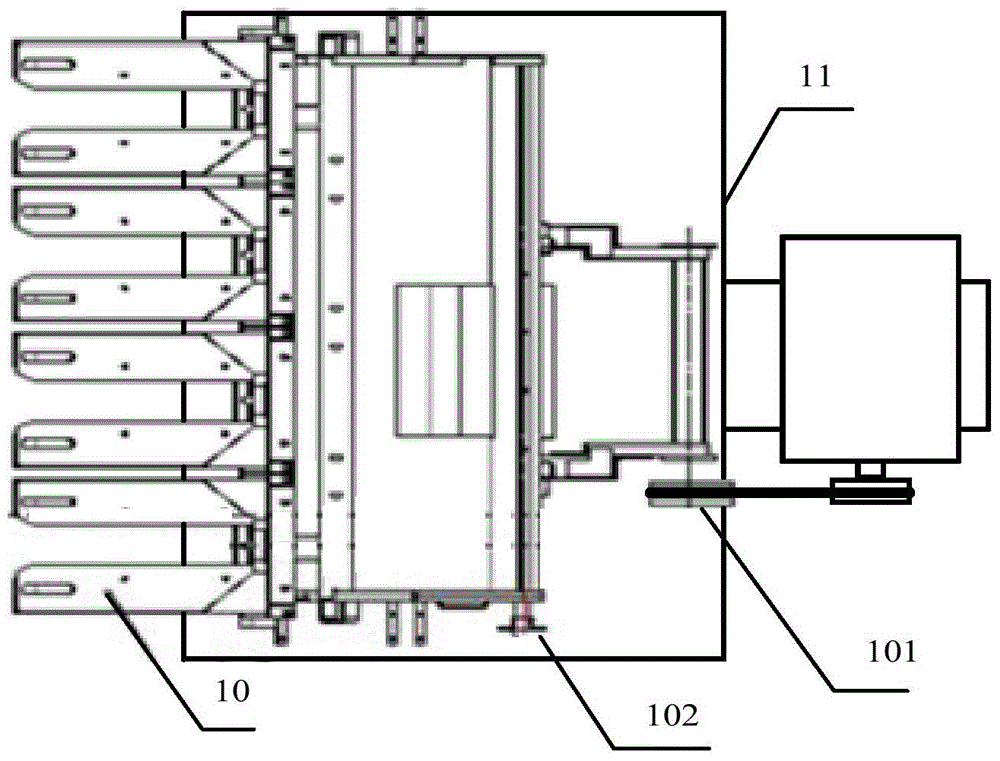

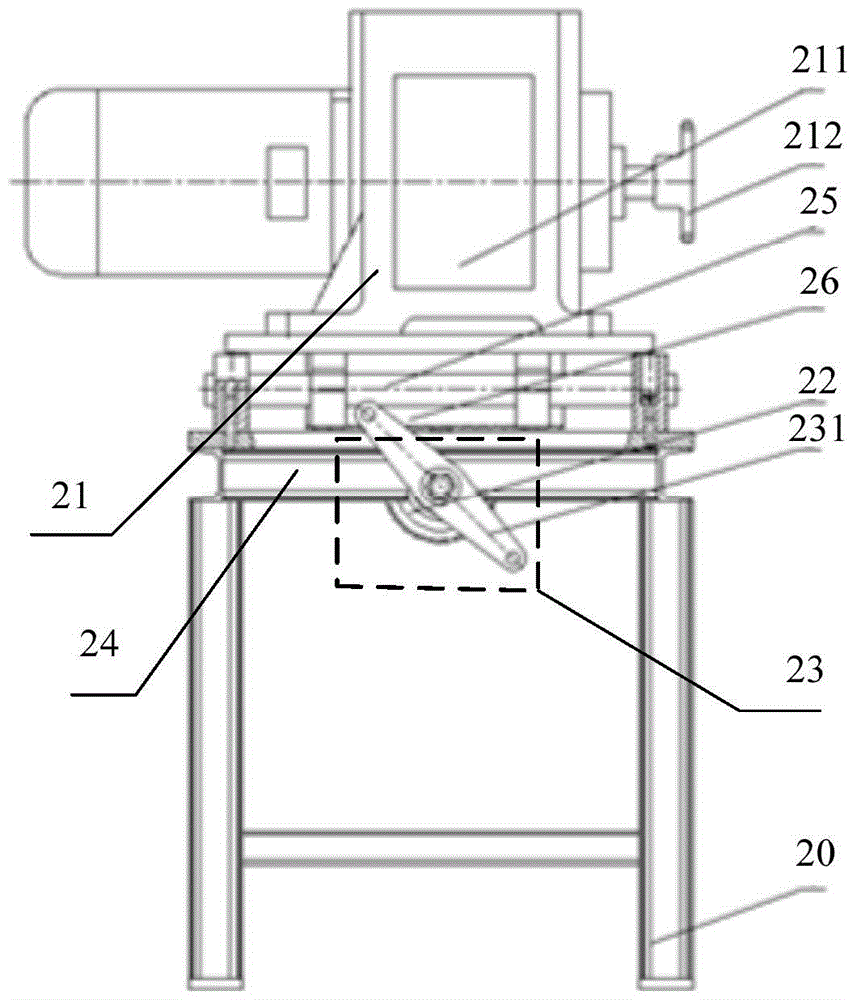

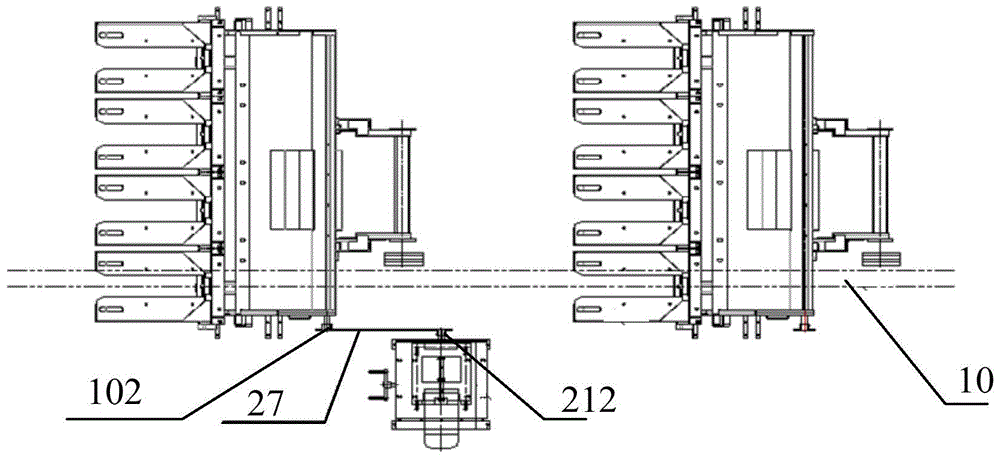

[0024] This embodiment discloses an online running-in platform, such as figure 2 As shown, the online running-in platform includes a frame 20, a running-in motor base 21 and a running-in motor 211 arranged on the running-in motor base 21, and an output sprocket 212 is arranged on the shaft of the running-in motor base 211.

[0025] The frame 20 is welded by structural steel. After welding, it undergoes artificial aging treatment to eliminate internal stress and reduce deformation. The upper plane is processed after welding to ensure its flatness and reduce the cumulative error caused by assembly and other factors.

[0026] The online running-in station also includes:

[0027] The positioning gear 22 arranged on the frame 20 and the driving device 23 axially connected with the positioning gear 22 can drive the positioning gear 22 to rotate. In this embodiment, the driving device 23 includes a driving handle 231 , and the driving handle 231 includes two symmetrical rocker arms...

Embodiment 2

[0041] This embodiment discloses another online running-in station, which is different from the above embodiment in that, as Figure 4 As shown, the drive unit includes:

[0042] The driven sprocket 31 fixed on the positioning gear 22 and coaxial with the positioning gear 22, the driven sprocket 31 and the positioning gear 22 are coaxial gears, and the driven sprocket 31 The diameter is smaller than the diameter of the positioning gear 22 .

[0043] The driving motor 32 and the driving sprocket 33 connected with the rotating shaft of the driving motor 32 . A driving motor connecting seat 321 is additionally provided on the frame 20 , and the driving motor 32 is fixed on the driving motor connecting seat 321 . The driving sprocket 33 is connected with the driven sprocket 31 through a driving chain 34 .

[0044] The online running-in station also includes a drive motor controller 35 connected to the drive motor 32 and used to control the steering of the drive motor 32 . The ...

Embodiment 3

[0047] This embodiment discloses yet another online running-in station, which is different from the above embodiment in that, as Figure 5 As shown, the online running-in station also includes:

[0048] Transmission shaft 40, the transmission shaft 40 is connected to the output sprocket 212 and the input sprocket of the wheat harvester. In addition, the transmission shaft 40 can also connect the output sprocket 212 and the input sprocket of the threshing chamber.

[0049] Among them, such as Image 6 As shown, the drive shaft 40 includes:

[0050] The sprocket joint 41 is used for connecting the output sprocket 212 .

[0051] The connecting shaft 42 is connected to the sprocket joint 41 through the first universal joint 421 . The connecting shaft 42 is composed of a shaft sleeve and a shaft. The shaft and the shaft sleeve are connected by a spline, and the shaft can slide freely on the shaft sleeve to adjust the length of the shaft; the spline connection can transmit a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com