Machine tool rotating shaft geometry error six-circle identifying method based on measuring of ball bar instrument

A technology of geometric error and identification method, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as lack of generality, and achieve good systematic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

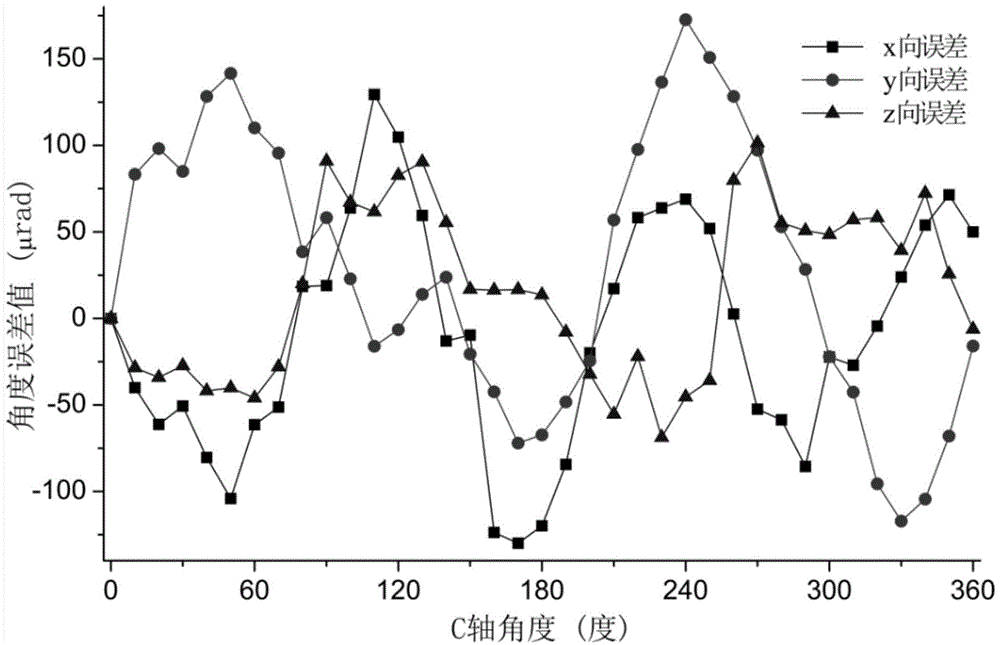

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

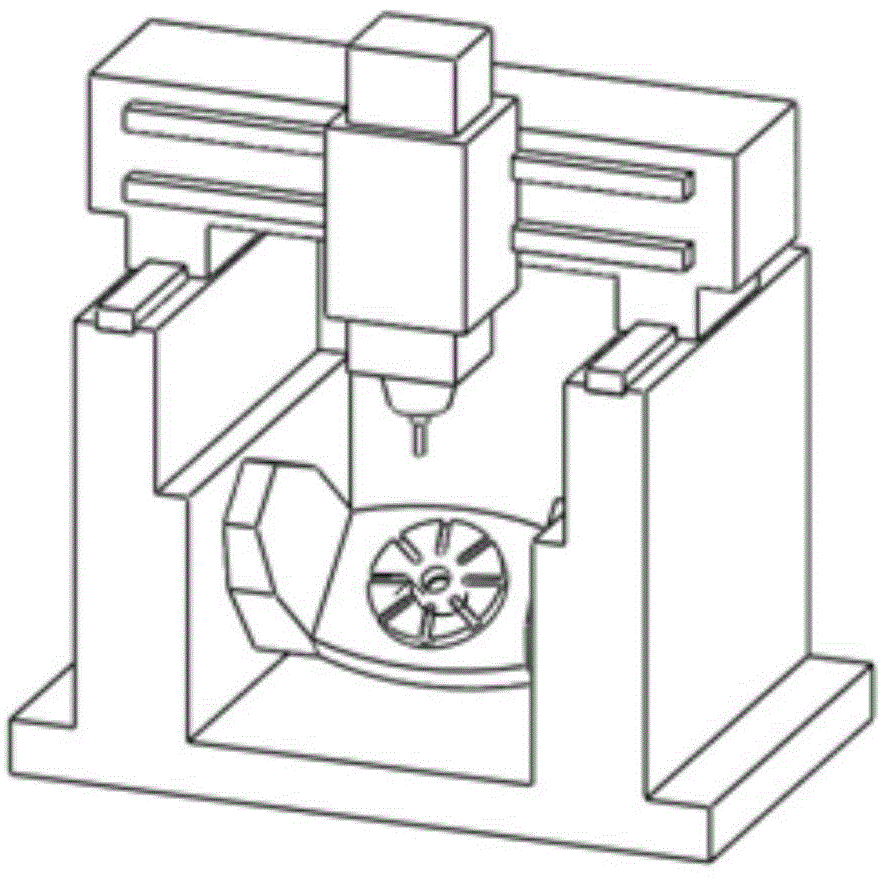

[0041] attached Figure 5 Shown is the flow chart of the six-circle identification method of the geometric error of the machine tool rotation axis based on the ballbar measurement of the present invention, with the attached figure 1 Shown is a schematic structural diagram of a five-axis CNC machine tool, and the method of the present invention is illustrated by taking the machine tool as an example.

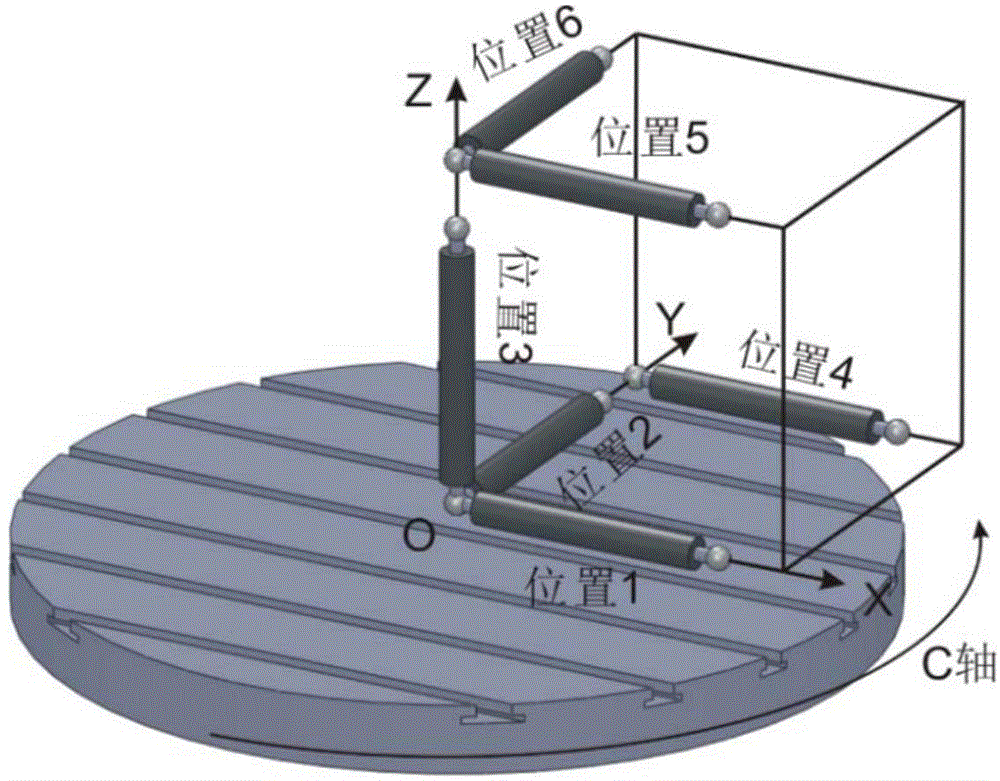

[0042] In step 1, according to the specific type and position of the machine tool's rotary axis, determine the six measurement positions of the ballbar in the rotary axis coordinate system, including steps:

[0043] Step 1.1. Determine the machine tool rotation axis type as A axis and C axis. This embodiment takes the machine tool C axis as an example. According to the structure of the machine tool and the position of the C-axis, set the origin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com