Dynamic sealing calorimeter with fault-tolerant structure

A technology of dynamic sealing and calorimeter, applied in the field of teaching instruments, can solve problems such as unaligned, unreasonable structural design, and loose sealing, and achieve the effect of no principle error, good dynamic sealing, and reduction of heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

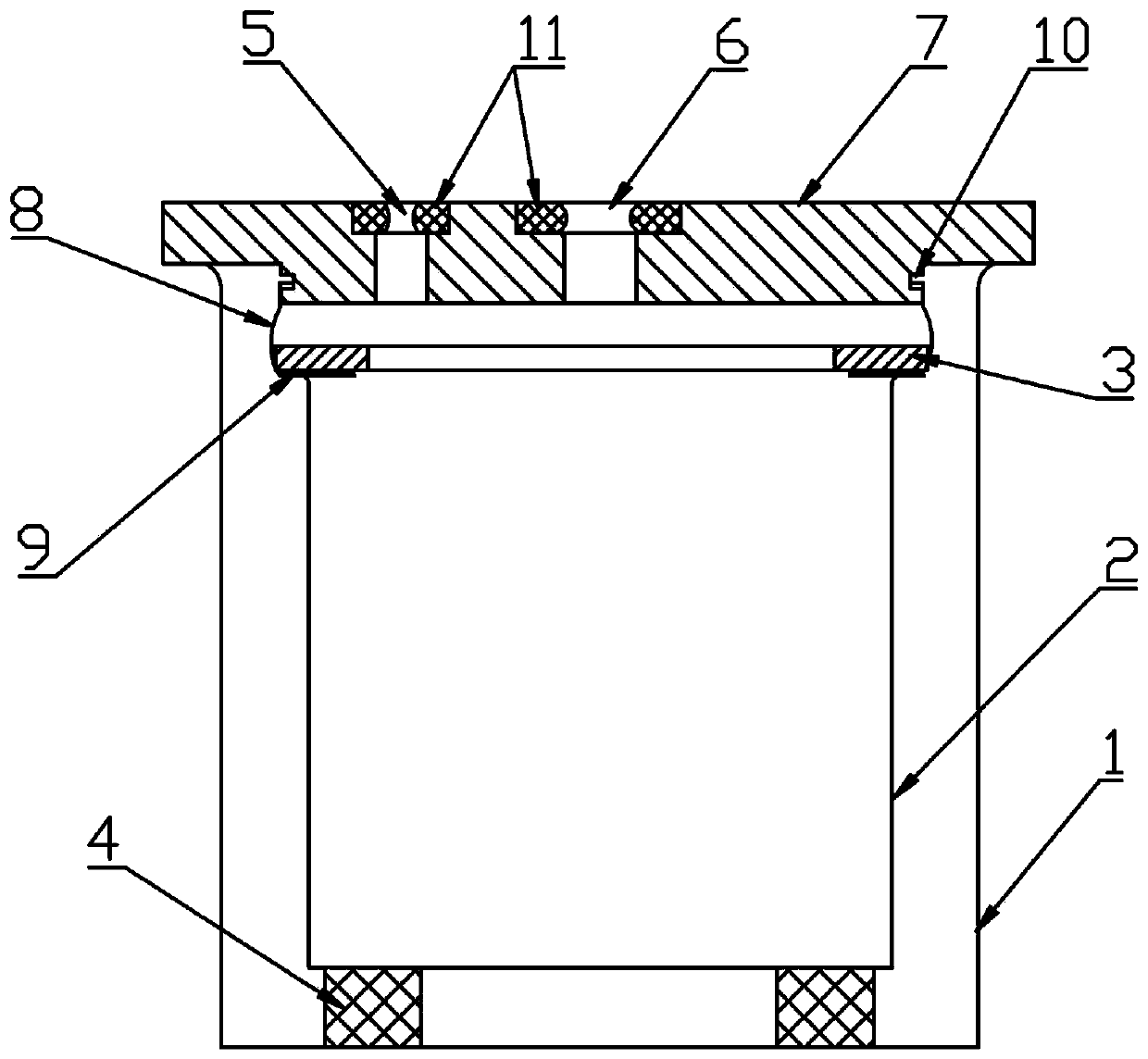

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

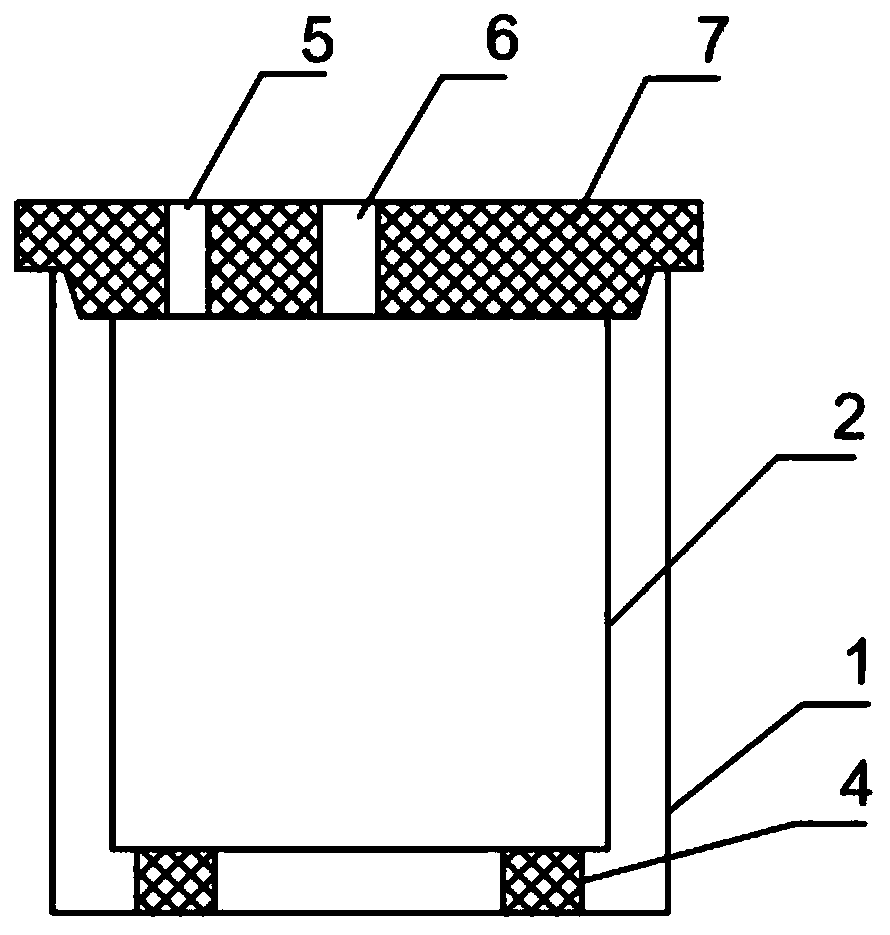

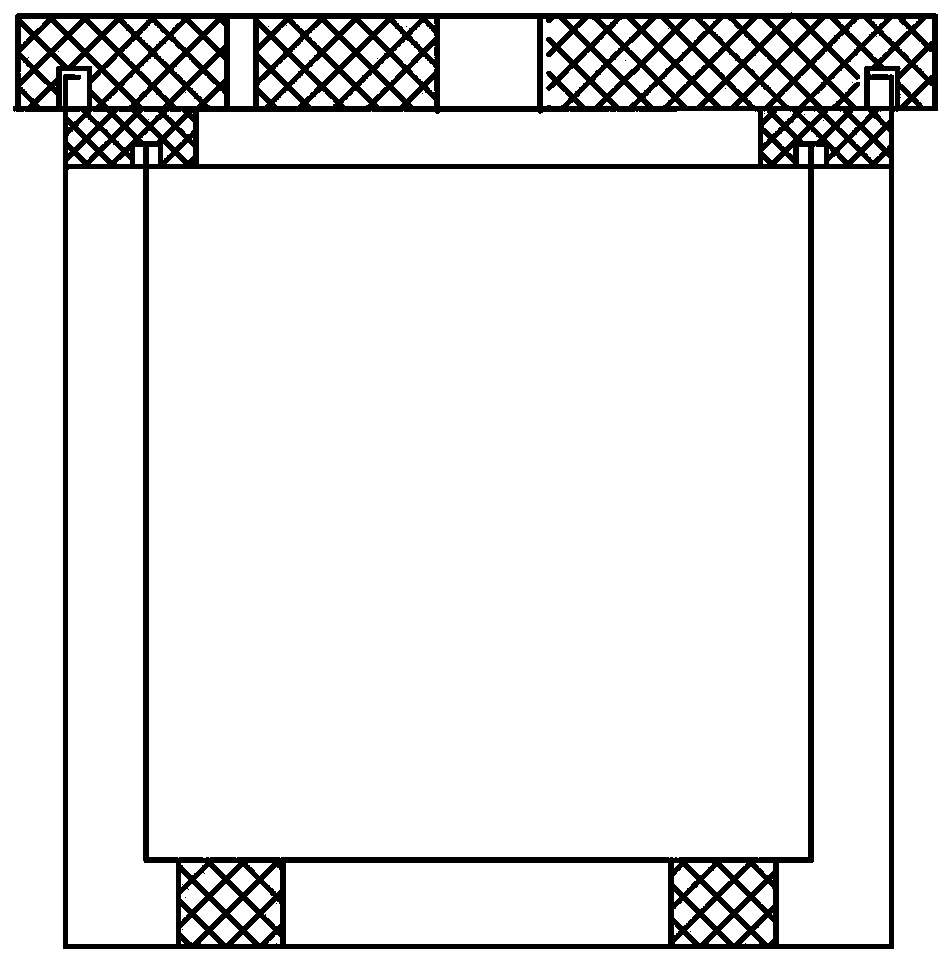

[0022] A dynamic sealed calorimeter with fault-tolerant structure, such as image 3 As shown, including: outer cylinder 1, inner cylinder 2, rubber ring 3, gasket 4, stirrer socket 5, thermometer socket 6, rubber cover 7, sealing cylinder 8, soft rubber gasket 9, ring groove 10, small seal Ring 11; both the outer cylinder 1 and the inner cylinder 2 are made of metal cylinders with closed bottom ends, the upper edge of the cylinder mouth is made into an arc shape, and the inner cylinder 2 is placed at the bottom of the outer cylinder 1 through a heat-insulating gasket 4 , There is a uniform gap between the inner cylinder 2 and the outer cylinder 1.

[0023] The rubber cover 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com