A method of axially layered cutting of large-pitch threads, a tool wear test method, and a method for calculating mechanical and thermal loads

A technology of axial layering and thread cutting tools, applied in the direction of thread cutting machine, thread cutting device, manufacturing tools, etc., can solve the problems of large cutting force, affecting the quality of machined surface and machining accuracy, and wear, and achieve the effect of eliminating principle errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

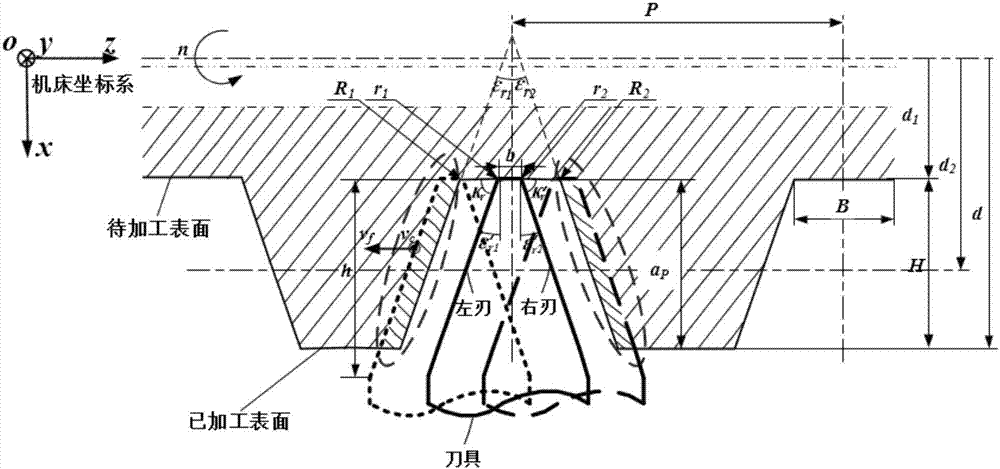

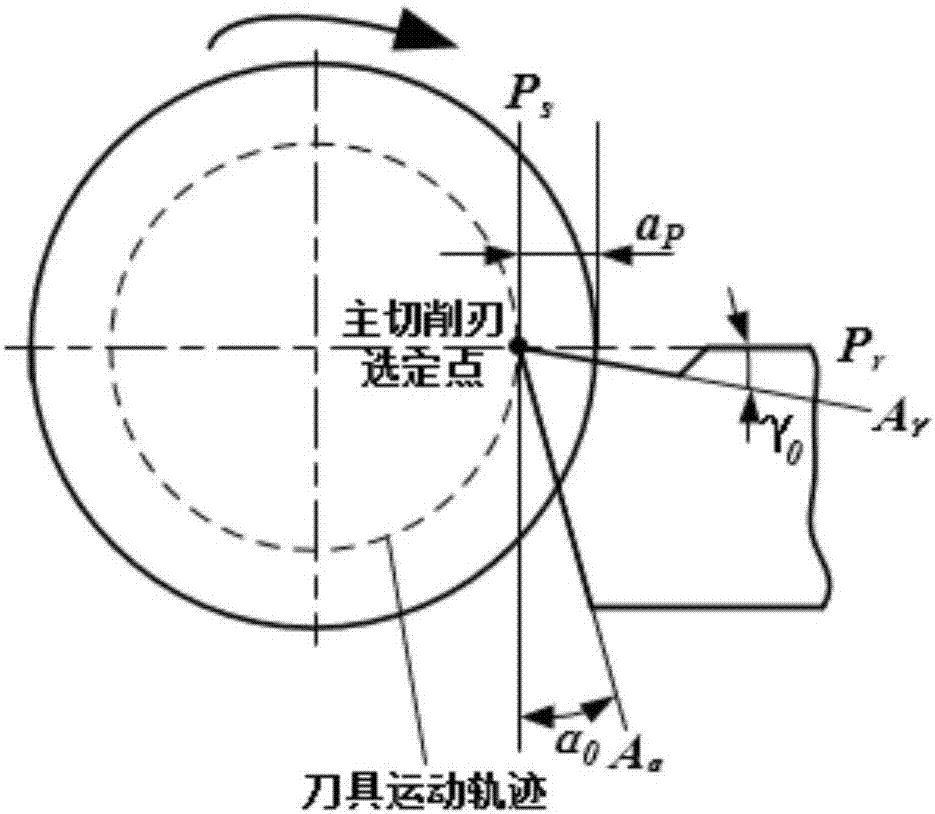

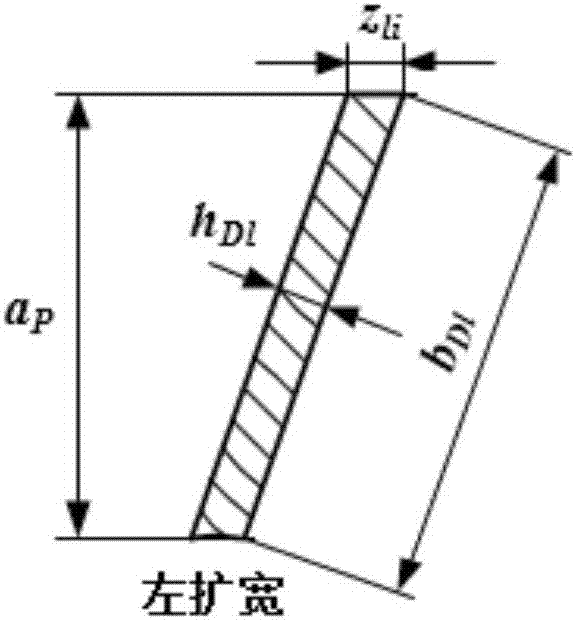

[0050] refer to Figure 1 to Figure 5 , the axial layered cutting method for turning large-pitch threads adopts a tool with left and right cutting edges to turn the left and right thread surfaces of large-pitch thread specimens in layers in the axial direction. In the figure: n is the workpiece speed, v f is the tool axial feed rate, v c is the main motion speed, and the Cartesian coordinate system perpendicular to each other is formed between them; κ r is the cutting edge angle of the tool, κ r ’ is the secondary deflection angle of the tool, γ 0 is the secondary relief angle of the tool, α 0 is the tool rake angle, Φ is the helix angle of the test piece, ε r1 , ε r2 are the left and right flank angles of the thread respectively, ε r1 ' is the left edge side angle of the tool, ε r2 ' is the right edge side angle of the tool; d is the outer diameter of the test piece, d 1 is the small diameter of the specimen, d 2 is the pitch diameter of the specimen, d w H is the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com