Composite knitted fabric for car seat cushion

A technology for knitted fabrics and car seat cushions, applied in thigh cushions, synthetic resin layered products, layered products, etc., can solve the problems of lack of air permeability and easy skin problems of seat cushions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

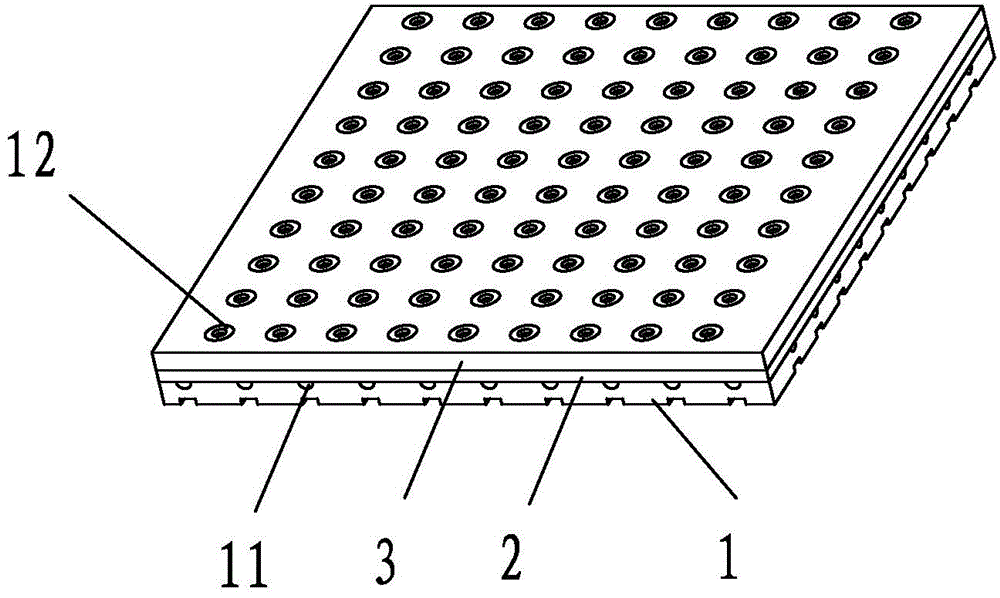

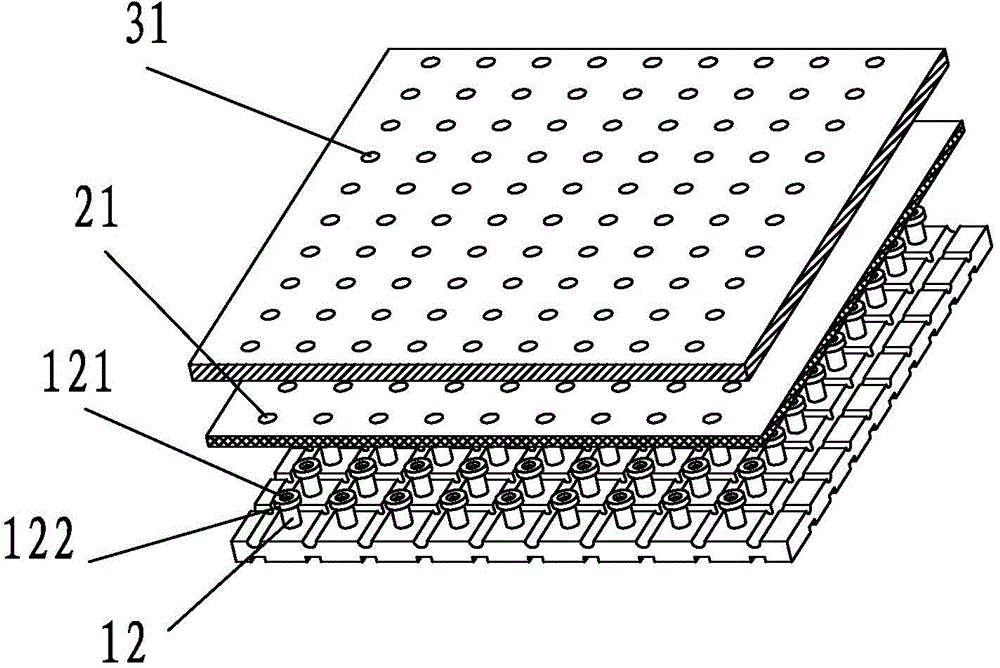

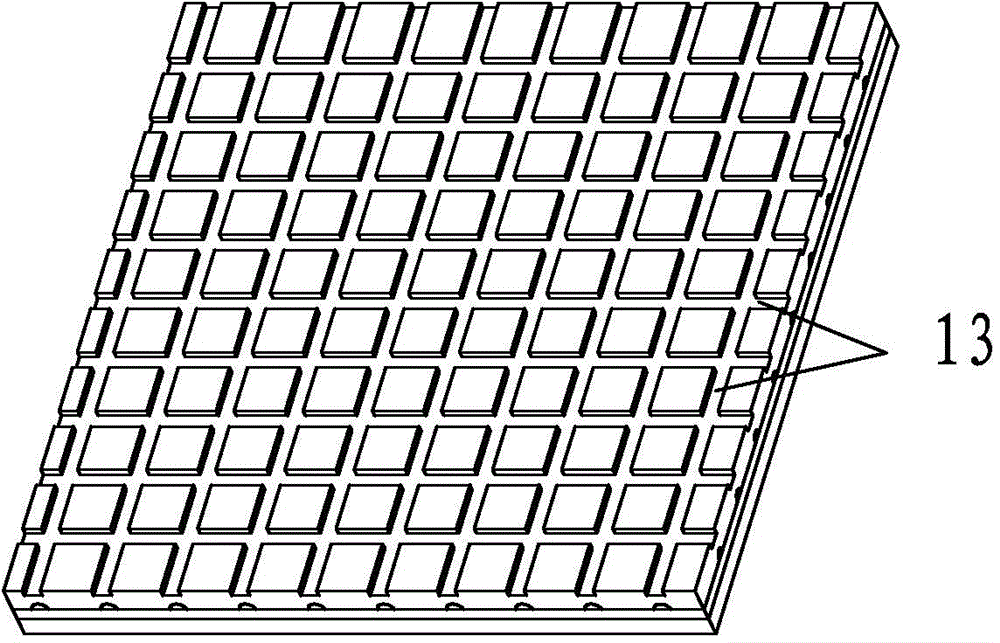

[0016] Such as Figure 1 to Figure 4 As shown, a composite knitted fabric used for car seat cushions includes a rubber bottom layer 1 located at the bottom. The rubber bottom layer is made of rubber material. There will be no movement on the car seat. The top surface of the rubber bottom layer is provided with more than two air guide grooves 11 in parallel in the vertical direction. A round hole 121 is provided on the top surface of the raised portion, and a cushioning cotton layer 2 is covered above the rubber bottom layer, and the cushioning cotton layer is provided with a cotton layer through hole 21 for the columnar raised portion to pass through, and a knitted cloth 3 is covered above the cushioning cotton layer, The knitted fabric is also provided with a knitted fabric through hole 31 for the columnar protrusions to pass through. The top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com