Laminate drop prevention mechanism for PCB (Printed circuit board) laminate trolley

A technology of pressing plate and transfer table, which is applied in the direction of transporting passenger cars, railway car body parts, cargo supporting/fastening parts, etc., can solve problems such as falling of pressing plates, and achieve the effect of preventing the falling of pressing plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

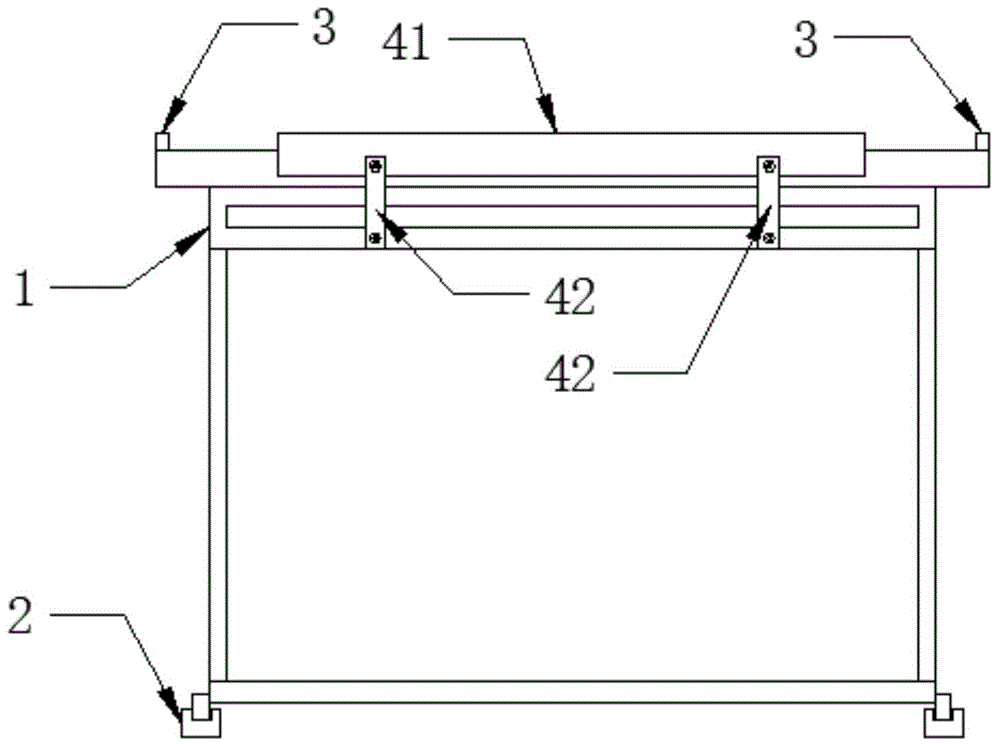

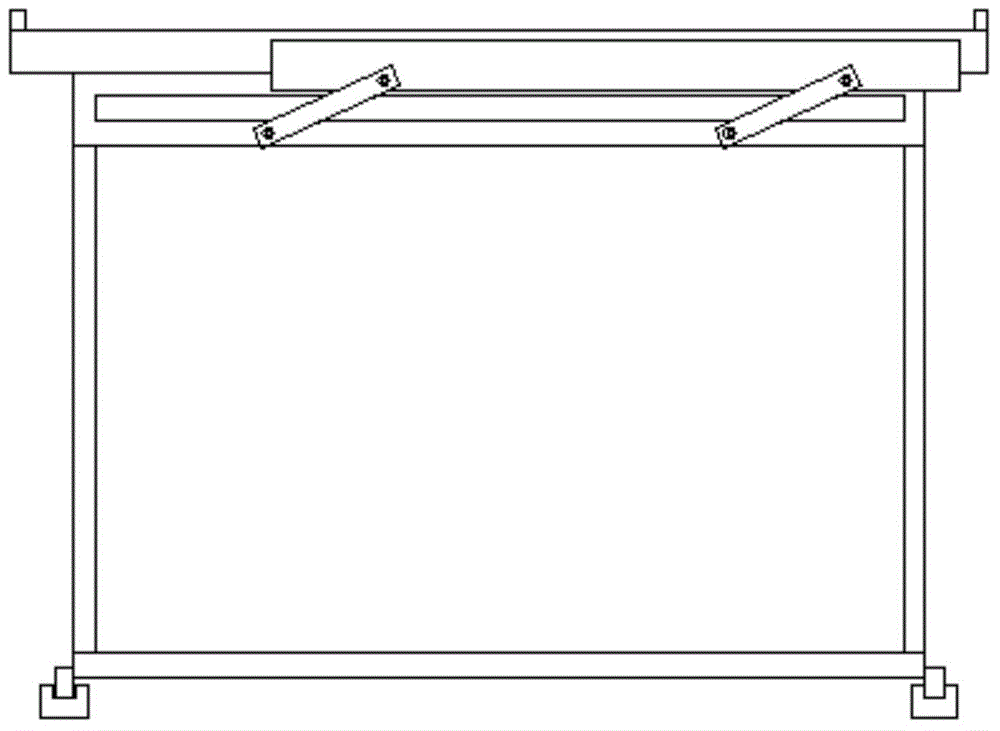

[0012] Embodiment 1: An anti-dropping mechanism of a PCB press-fitting plate transmission trolley, the transmission trolley 1 runs along the track 2, and the trolley has left and right sides parallel to the direction of the track and front and rear ends perpendicular to the direction of the track , the left and right sides of the trolley are all provided with side baffles 3 higher than the table, and the front and rear ends of the trolley are all provided with movable baffle mechanisms, and the movable baffle mechanisms are: the The front and rear ends of the trolley are all equipped with a movable frame, and the movable frame is formed by connecting the upper beam 41 and two vertical bars 42. The two vertical bars are arranged in parallel, and the lower ends of the two vertical bars are all fixed on the trolley. The upper end is connected to the upper beam, and the connection between the upper beam and the vertical bar is connected by bolts and nuts. When the vertical bar and ...

Embodiment 2

[0013] Embodiment 2: As a modification of Embodiment 1, an end baffle may also be provided, the vertical bar and the upper beam are all lower than the table, and the upper beam is fixed with an end baffle, when the vertical bar and the upper beam form a vertical State, end baffle is higher than table top, and end baffle can be lower than table top when vertical bar and upper crossbeam constitute non-perpendicular state, the size of movable frame (upper crossbeam and vertical bar) in this embodiment (especially Left and right dimension) can be designed smaller than that in embodiment 1, and the movable frame does not serve as the baffle function but only as a mechanism for the height of the lifting end baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com