Novel sensitized bubble carrier colloidal emulsion explosive and preparation method thereof

A technology of emulsified explosives and sensitized gas, which is applied in the direction of explosives, etc., can solve the problems of unsuitability for specialized chemical factories, high performance of emulsified explosives, and high manufacturing cost, and achieve the effects of small environmental impact, excellent explosive performance, and easy operation of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

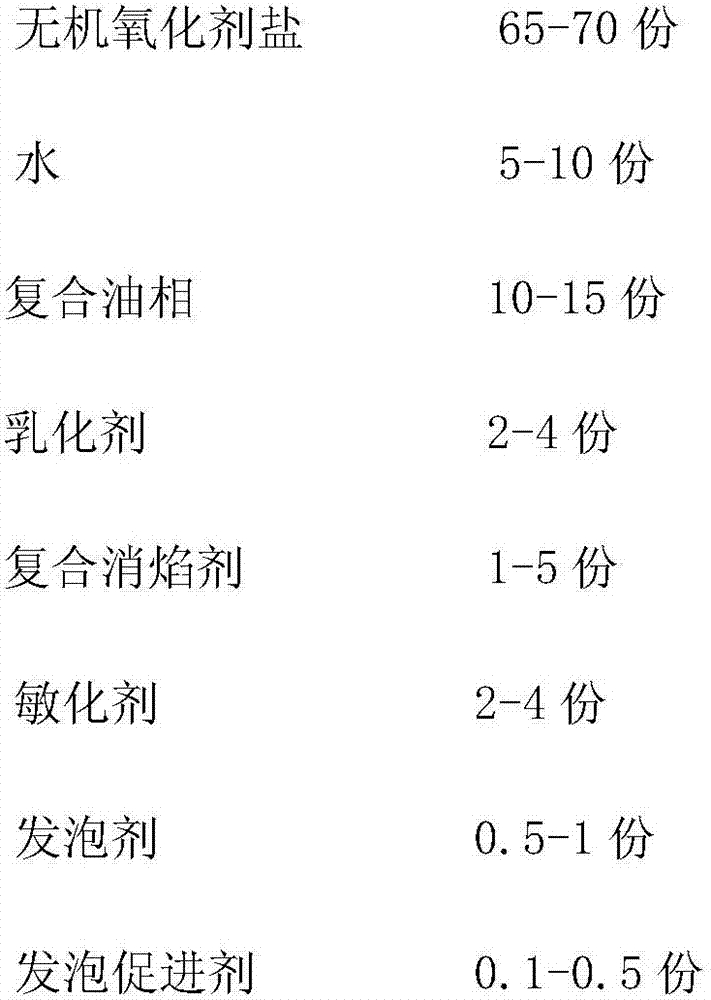

[0046] This embodiment provides a novel sensitized bubble carrier colloidal emulsifier explosive, and the components are as follows by mass percentage:

[0047] Inorganic oxidant salt: 65 parts, water: 5 parts, paraffin wax: 6 parts, vaseline: 3 parts, animal oil: 3 parts, vegetable oil: 3 parts, polyisobutene dianhydride-triethanolamine emulsifier: 3 parts, compound flame suppressant: 5 parts, MgH 2 : 2 parts, resin microspheres: 1 part, sodium nitrite: 0.5 parts, acetic acid: 0.3 parts;

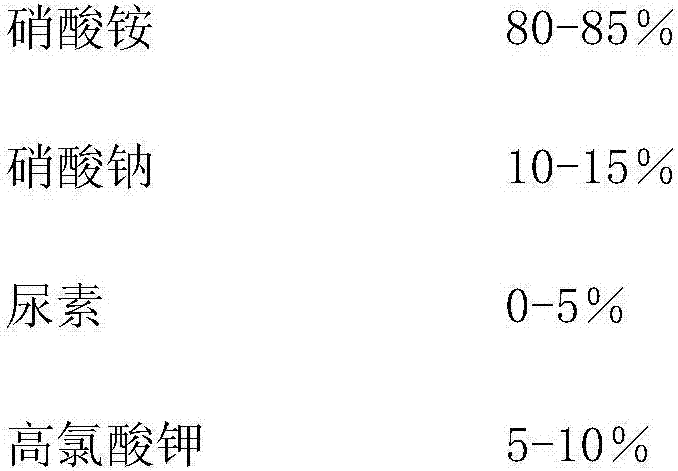

[0048]The inorganic oxidant salt is a mixture of ammonium nitrate, sodium nitrate and urea, and the percentage by weight is ammonium nitrate: 80%, sodium nitrate: 10%, urea: 5%, potassium perchlorate: 5%; the composite flame suppressant is sodium chloride, The mixture of potassium chloride and ammonium chloride has a weight ratio of sodium chloride: potassium chloride: ammonium chloride = 1.5:2:1.

[0049] The preparation method of polyisobutylene diacid anhydride-triethanolamine emulsifi...

Embodiment 2

[0053] This embodiment provides a novel sensitized bubble carrier colloidal emulsifier explosive, and the components are as follows by mass percentage:

[0054] Inorganic oxidant salt: 70 parts, water: 8 parts, paraffin wax: 4 parts, vaseline: 2 parts, animal oil: 2 parts, vegetable oil: 2 parts, polyisobutylene dianhydride-triethanolamine emulsifier: 4 parts, compound flame suppressant: 3 parts, MgH 2 : 2.8 parts, resin microspheres: 1.4 parts, sodium nitrite: 0.55 parts, sulfuric acid: 0.5 parts,

[0055] Wherein: the inorganic oxidizing agent salt is the mixture of ammonium nitrate, sodium nitrate and urea, and percentage by weight is: ammonium nitrate: 85%, sodium nitrate: 10%, potassium perchlorate: 5%; The mixture of potassium and ammonium chloride has a weight ratio of sodium chloride: potassium chloride: ammonium chloride = 1.5:2:1.

[0056] The preparation method of polyisobutylene diacid anhydride-triethanolamine emulsifier is as follows:

[0057] (1) Take 100g o...

Embodiment 3

[0060] This embodiment provides a novel sensitized bubble carrier colloidal emulsifier explosive, and the components are as follows by mass percentage:

[0061] Inorganic oxidant salt: 68 parts, water: 10 parts, paraffin wax: 4.8 parts, vaseline: 2.4 parts, animal oil: 2.4 parts, vegetable oil: 2.4 parts, polyisobutylene diacid anhydride-triethanolamine emulsifier: 2 parts, composite flame suppressant: 1 part, sensitizer: 2 parts, H foaming agent: 1 part, phosphoric acid: 0.1 part;

[0062] Wherein: the inorganic oxidizing agent salt is the mixture of ammonium nitrate, sodium nitrate and urea, and percentage by weight is: ammonium nitrate: 82%, sodium nitrate: 12%, urea: 1%, potassium perchlorate: 5%, compound flame suppressant is chlorine A mixture of sodium chloride, potassium chloride and ammonium chloride, the weight ratio of which is sodium chloride: potassium chloride: ammonium chloride = 1.5:2:1.

[0063] The preparation method of polyisobutylene diacid anhydride-triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com