A kind of industrialized preparation method of improved mitiglinide calcium

A technology of mitiglinide calcium and target compounds, which is applied in the field of organic synthesis and preparative chemistry, can solve the problems of unsuitability for industrial production, many types of reagents, and lengthy steps, and achieve the goals of shortening the production cycle, increasing the yield, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

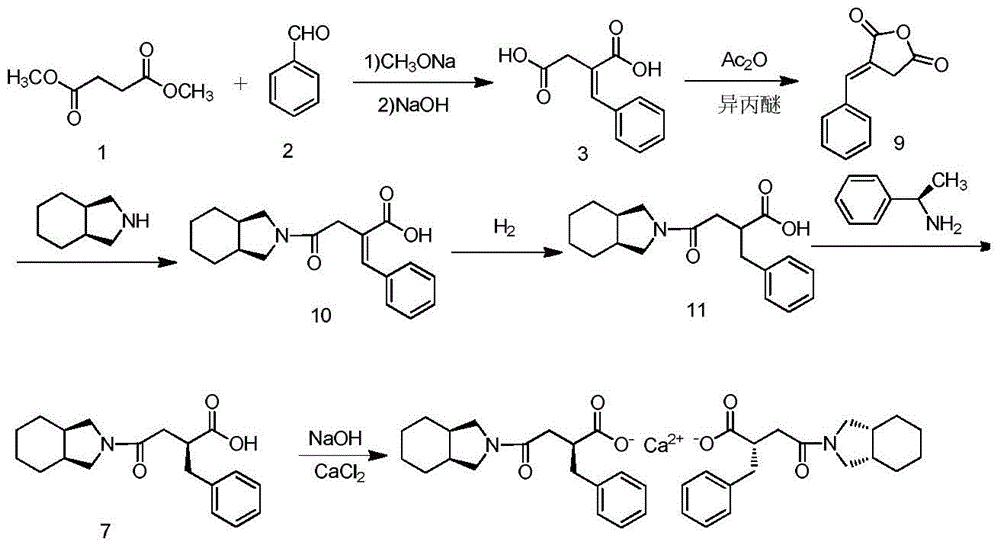

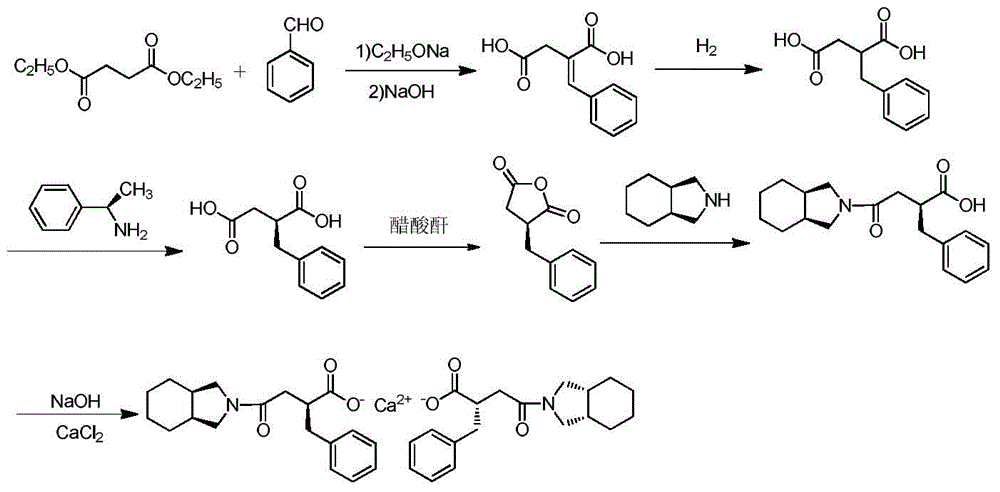

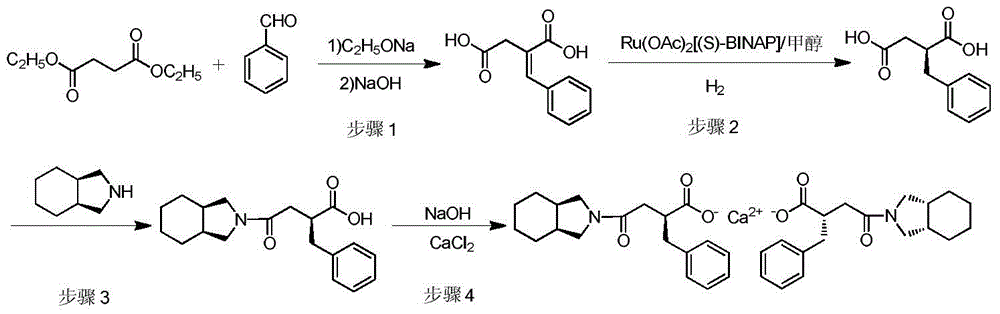

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Preparation of 2-benzylidene succinic acid

[0039] Sodium methoxide (9kg) and methanol (48L) were put into a 100L reactor, stirred and dissolved, and poured into a 50L high-level tank. Dimethyl succinate (20kg) is dropped into 200L reaction still, heated to reflux, the methanol solution of sodium methoxide in the high level tank is added dropwise rapidly, the dropwise reflux reaction is 30min, and benzaldehyde (10.9kg) is added dropwise under the reflux state, After dropping, reflux and stir for 3-5 hours. HPLC detects that the benzaldehyde reaction is complete. Add 4N NaOH aqueous solution (38L) dropwise, and react under reflux for 4-6 hours after dropping. Dried to obtain 19kg of light yellow solid, ie Intermediate 1, with a yield of 90%. Step 2: Preparation of (S)-2-benzylsuccinic acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com