Magnetic polymer based on polyethyleneimine and its preparation method

A polyethyleneimine and polymer technology, which is applied in the field of polyethyleneimine-based magnetic polymers and their preparation, can solve the problems of complex process, high cost, poor compatibility and the like, and achieves simple process, low cost and stable performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] magnetic polymer A 1 Synthesis:

[0026]

[0027] (1) Dissolve linear PEI (270.8 mg, 6.3 mmol) with a molecular weight of 600 Da in 5 ml of absolute ethanol, and add dropwise into iodomethane (4 ml, 64.2 mmol). Stir at 42° C. for 60 h, centrifuge after the reaction to obtain a yellow solid which is dissolved in water, precipitate in ethanol, centrifuge, and vacuum-dry to obtain the intermediate product 1a.

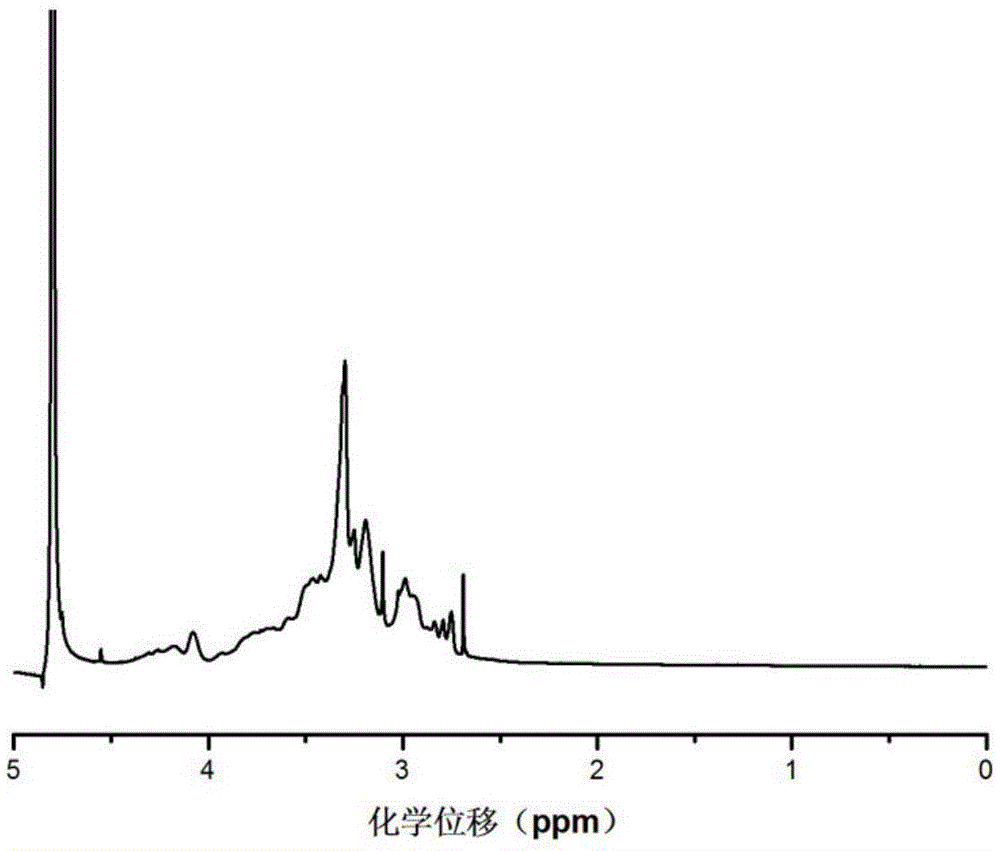

[0028] (2) Dissolve 1a (146.0 mg, 1.0 mmol) in water, add 4 g of chloride ion exchange resin to the system and stir for 8 h. After filtration, the filtrate was rotary evaporated and dried in vacuo to obtain light yellow solid 1b. According to the elemental analysis in Table 1, the quaternization conversion rate was 66%. Such as figure 1 Shown is the H NMR spectrum of 1b, 1 HNMR (500Hz,D 2 O) Chemical shift δ: 3.2-3.6 (multiple peaks, -CH connected to the quaternization unit 2 -, -CH 3 ), 2.7-3.2 (multiplet, -CH connected to PEI unit 2 -).

[0029] (3) 1b...

Embodiment 2

[0031] magnetic polymer A 2 Synthesis:

[0032]

[0033] (1) Dissolve linear PEI (268.7 mg, 6.2 mmol) with a molecular weight of 1000 kDa in 5 ml of absolute ethanol, and add dropwise into iodomethane (3.9 ml, 62.6 mmol). Stir at 50° C. for 100 h, centrifuge after the reaction to obtain a yellow solid which is dissolved in water, precipitate in ethanol, centrifuge, and vacuum-dry to obtain the intermediate product 2a.

[0034] (2) Dissolve 2a (175.6mg, 1.0mmol) in water, add 4g of chloride ion exchange resin to the system and stir for 12h. After filtration, the filtrate was rotary evaporated and dried in vacuo to obtain light yellow solid 2b. According to the elemental analysis in Table 1, the quaternization conversion rate was 85%.

[0035] (3) 2b (83.2mg, 1.0mmol) and FeCl equivalent to the quaternization unit 3 ·6H 2O (170.4mg, 0.633mmol) was dissolved in 5ml of methanol, stirred for 24h, suspended and evaporated, the product was washed with anhydrous ether, centrifu...

Embodiment 3

[0037] magnetic polymer A 3 Synthesis:

[0038]

[0039] (1) Linear PEI (268.7mg, 6.2mmol) with a molecular weight of 10kDa was dissolved in 5ml of absolute ethanol, and added dropwise to iodomethane (0.23ml, 0.37mmol). Stirring at 20° C. for 1 h, after the reaction was completed, centrifuged to obtain a yellow solid which was dissolved in water, precipitated in ethanol, centrifuged, and dried in vacuo to obtain the intermediate product 3a.

[0040] (2) Dissolve 3a (82.1mg, 1.0mmol) in water, add 4g of chloride ion exchange resin to the system and stir for 12h. After filtration, the filtrate was rotary evaporated and dried in vacuo to obtain light yellow solid 3b. According to the elemental analysis in Table 1, the quaternization conversion rate was 25%.

[0041] (3) 3b (59.1mg, 1.0mmol) and FeCl equivalent to the quaternization unit 3 ·6H 2 O (170.4mg, 0.633mmol) was dissolved in 5ml of methanol, stirred for 24h, suspended and evaporated, the product was washed with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com