Underground comprehensive refrigerating method

A refrigeration method and refrigeration machine technology, which is applied in the fields of earth drilling, mine/tunnel ventilation, mining equipment, etc., which can solve the problems of increased underground water inflow, waste of mine investment, and inability to drain out, so as to achieve effective refrigeration costs and save Energy and water usage, effects of controlling cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

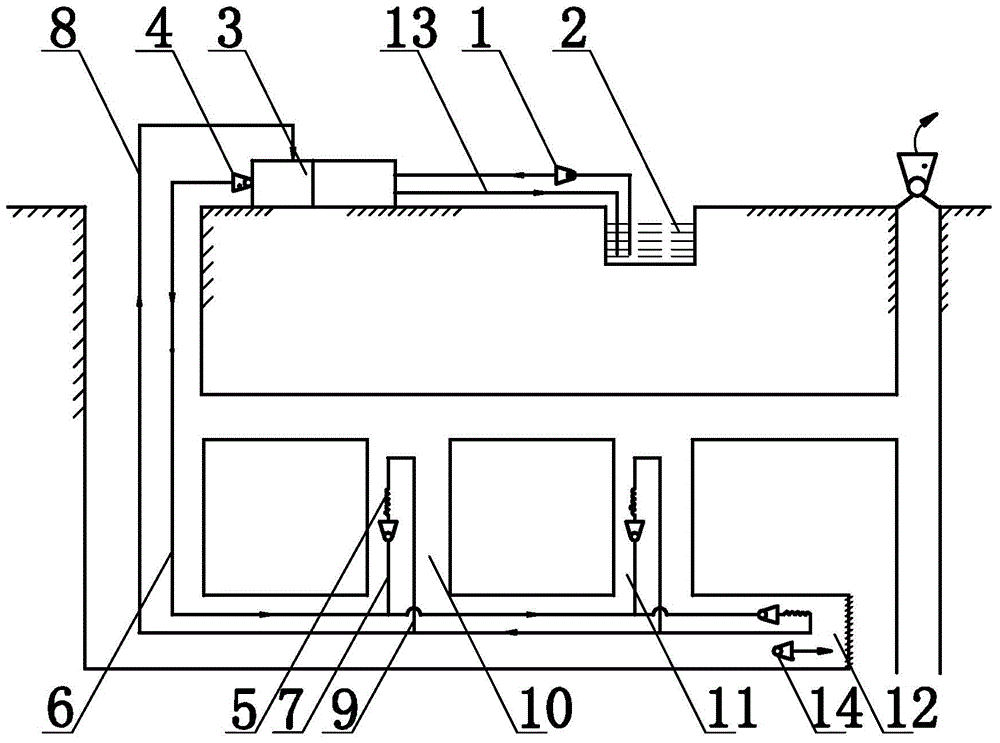

[0021] Embodiment 1: as figure 1 As shown, in the downhole comprehensive refrigeration method of the present invention, the water in the pool 2 is transported as a refrigerant to the refrigerator 3 through the water pump 1, and the refrigerator 3 cools down the water in the refrigeration compartment of the refrigerator 3 through the water in the pool 2 Make cold water, the cold water generated by the outlet of the refrigerator 3 is transported by the high-pressure water pump 4 through the water supply pipe to one end of the coil fan 5 in the mine, and the other end of the coil fan 5 is connected to the refrigerator 3 through the return pipe, and the coil fan 5. Through the cold water entering it, the cold wind is blown out.

Embodiment 2

[0022] Embodiment 2: On the basis of the structure described in Embodiment 1, the water in the pool 2 is mine groundwater located on the surface of the mining area. According to the water quantity and water temperature of the water in the pool 2, the mine groundwater is constantly added to the pool to supplement the water in the pool. The water quantity and reduce the temperature of the water in the pond, the water delivery pipeline and the return water pipeline comprise the water delivery main pipeline 6 and the water delivery branch pipeline 7 and the return water main pipeline 8 and the backwater branch pipeline 9, and there are stopes, chambers and independent mines under the mine The head excavation working face, the stope, the chamber and the single head excavation working face are all equipped with a coil fan 5, and one end of the main water supply pipe 6 and the main return water pipe 8 is connected to the refrigerator 3, and the other end is respectively connected to th...

Embodiment 3

[0023] Embodiment 3: On the basis of the structure described in Embodiment 2, a local ventilator 14 is arranged at the working face of the single-head excavation, and the cold air blown out by the coil fan 5 is sent to the working face, and the coil fan 5 and the local ventilator 14 They are explosion-proof coil fans and explosion-proof local fans with MA safety signs respectively. The refrigerator 3 is provided with a water return port, which is connected to the pool 2 through the return pipe 13, and the groundwater used by the refrigerator 3 is recycled to the pool. 2 for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com