Three-dimensional force tactile sensing unit based on the combination of capacitance and pressure-sensitive rubber

A tactile sensing and rubber combination technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of the contradiction between sensitivity and measurement range, it is difficult to take into account high sensitivity and large range, and the application of artificial tactile perception is limited, and the manufacturing process can be achieved. Simple, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

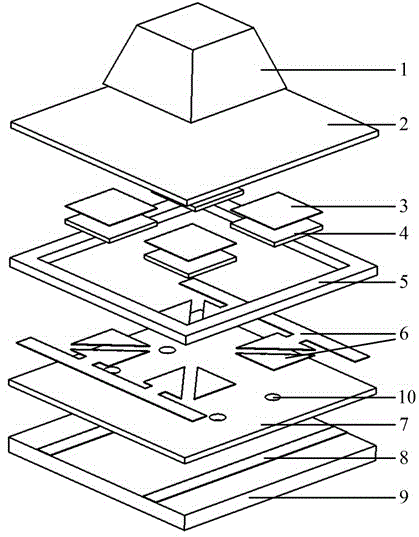

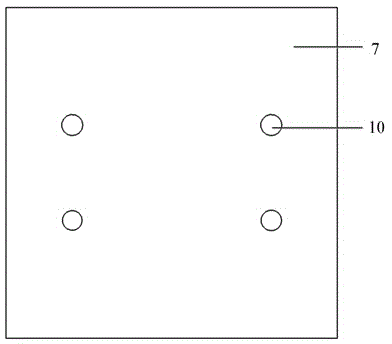

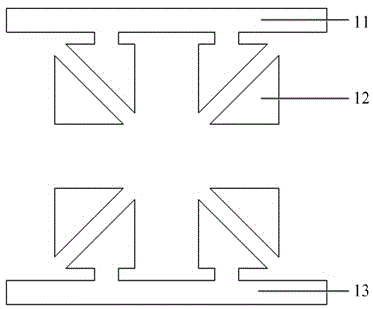

[0022] Such as figure 1 , Figure 4 , Figure 5 As shown, the three-dimensional force tactile sensing unit of the present invention consists of a surface PDMS protrusion 1, a third PI electrode substrate 2, a PDMS support layer 5, a capacitor plate layer 6, and a second PI electrode substrate from top to bottom. 7 and the first PI electrode substrate 9 are laminated; the four corners of the frame of the PDMS support layer 5 are respectively equipped with components composed of a square floating electrode 3 and a square pressure-sensitive rubber 4, and the four components have the same size and are different from each other. In contact with the framework of the PDMS support layer 5, the lower surface of the square floating electrode 3 in each component is attached to the upper surface of the square pressure-sensitive rubber 4, and the upper surface of the square floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com