Device and method for measuring microwave surface resistance distribution of high temperature superconducting thin film

A technology of microwave surface resistance and high-temperature superconducting thin film, which is applied in the field of superconducting electronics, can solve the problems of resolution, sensitivity and versatility, achieve high test resolution and sensitivity, avoid direct coupling, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

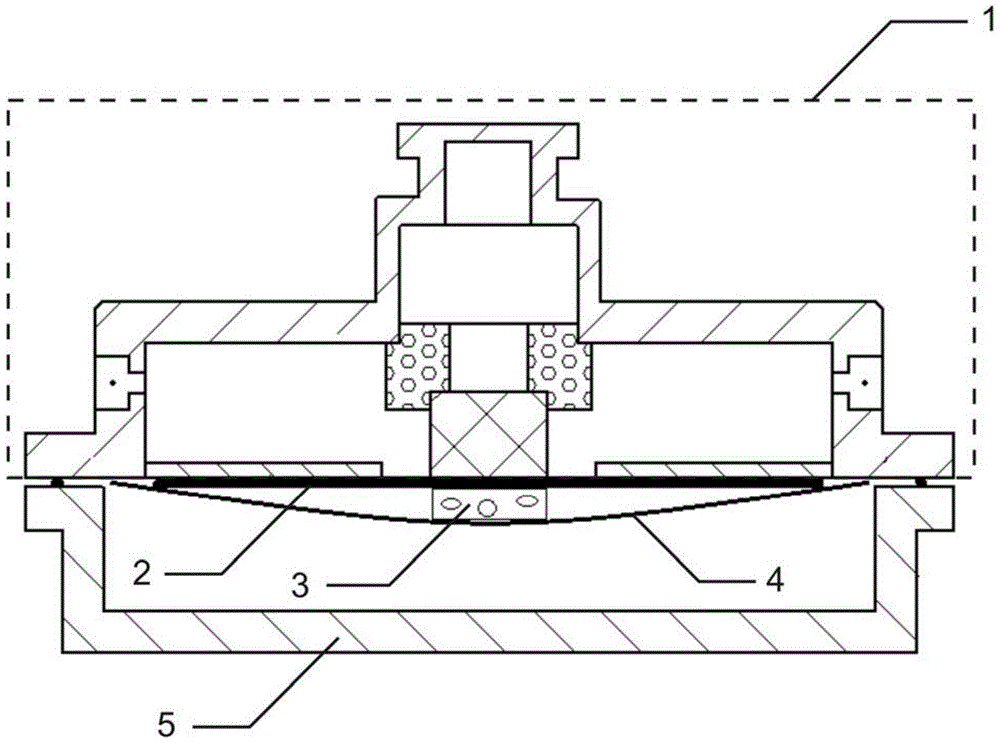

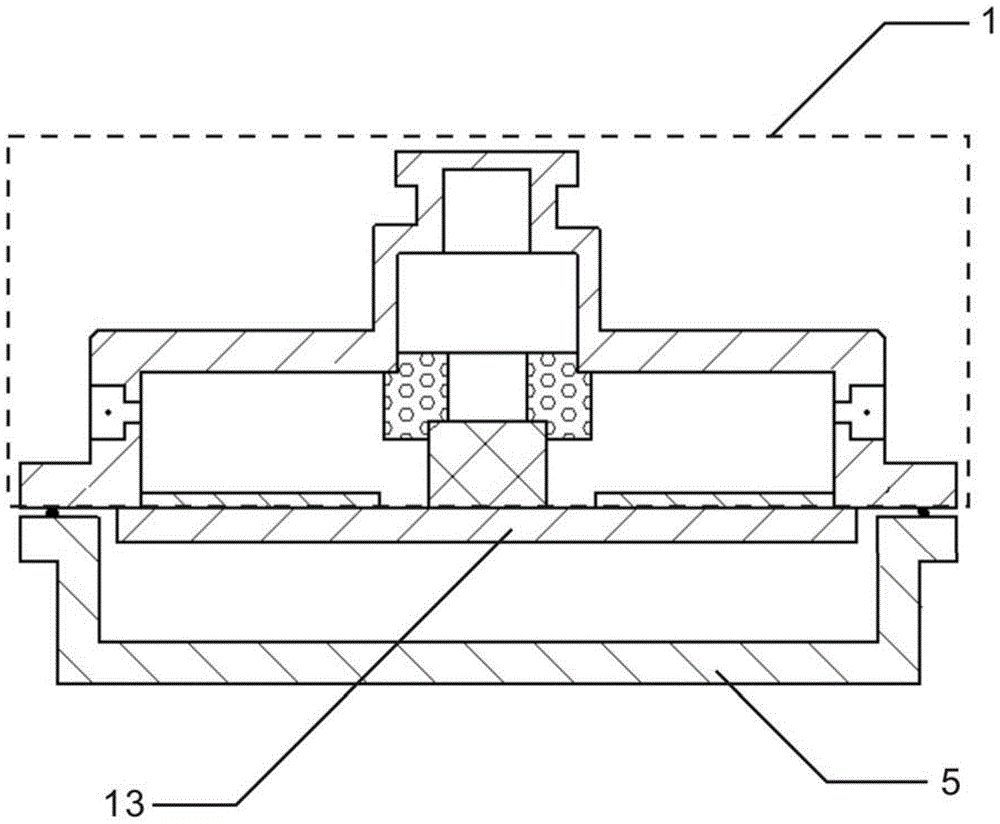

[0040] The high-temperature superconducting thin film microwave surface resistance distribution test device provided in this embodiment includes a test seat 1 , a fixing component, a calibration component and a sealing cover 5 .

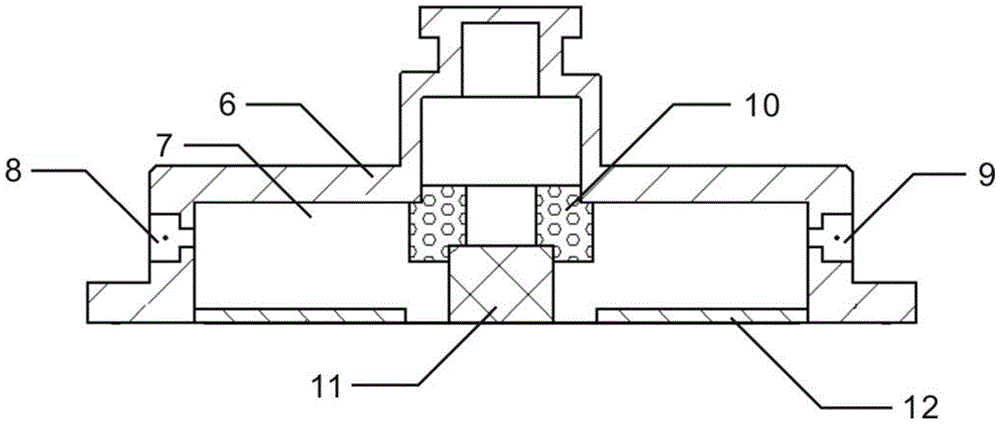

[0041] The schematic diagram of the test socket 1 is as follows: figure 2 As shown, it includes a shielding case 6 , an input coupling structure 8 , an output coupling structure 9 , a support ring 10 , a dielectric post 11 and a metal ring 12 . The dielectric column 11 is fixed on the support ring 10 and then fixed in the shielding shell 6. The metal ring 12 is embedded on the inner wall of the shielding shell 6. The thickness of the metal ring 12 ranges from 0.1mm to 0.5mm, and its inner diameter is slightly larger than The diameter of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com