Automatic elimination thickness meter

A thickness gauge and automatic technology, applied in the field of automatic rejection thickness gauge, can solve the problems of manual rejection, high leakage rate of defective products, waste of manpower, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

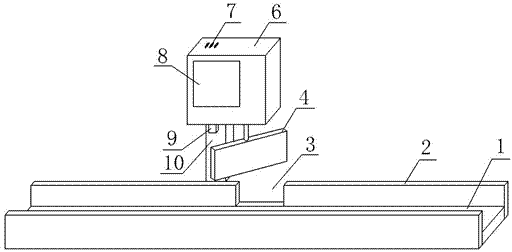

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the automatic rejecting thickness meter provided by the present invention includes a support column 10 and a thickness measuring box 6 arranged on the support column 10. The thickness measuring box 6 is provided with a touch screen 8, and the touch screen 8 can be used to display the thickness value of the current product. The number of products measured and the pass rate can also be checked through the touch screen 8 for previous thickness records, which is convenient for the staff to know the product quality in time; the top of the thickness measuring box 6 is provided with a sound outlet 7 .

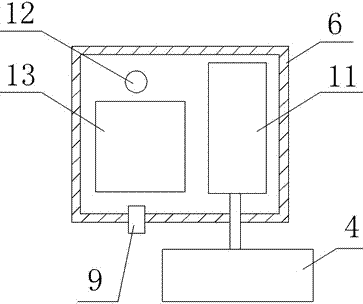

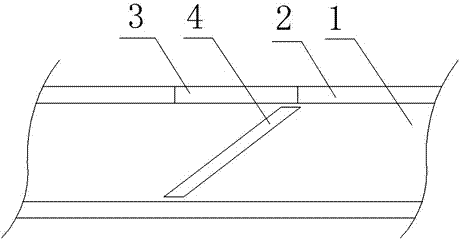

[0014] Such as figure 2 As shown, the automatic rejecting thickness meter provided by the present invention also includes a thickness measuring mechanism and a rejecting mechanism for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com