Hydraulic expanded connection tool

A technology of expansion joints and tooling, which is applied in the field of tooling and fixtures, can solve the problems of inability to realize full-thickness expansion joints, low service life of rubber expansion joints, and reduced service life, so as to achieve easy adjustment of expansion joint tightness, short manufacturing cycle and low manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

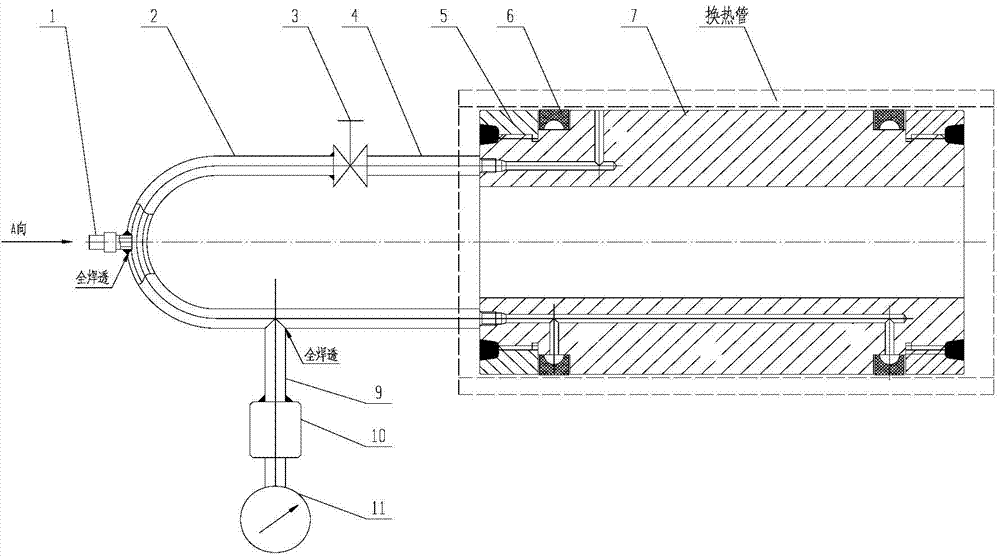

[0012] Such as figure 1 As shown, it includes pressure test bundle joint 1, elbow pipe 2, needle valve 3, joint 4, retaining ring 5, Y-shaped sealing ring 6, expansion head 7, straight pipe 9, gauge holder 10 and pressure gauge 11.

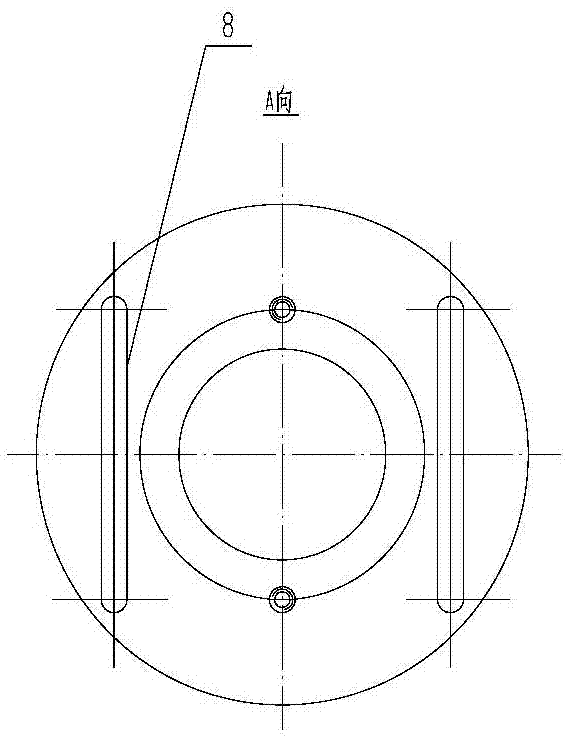

[0013] The two ends of the expansion head 7 are respectively fitted with retaining rings 5 and Y-shaped sealing rings 6, the joint 4 is fastened in the expansion head 7, the two ends of the elbow 2 are respectively connected with the joint 4, and the needle valve 3 is connected On the elbow 2, a pressure test beam joint 1 is welded on the elbow 2, and a straight pipe 9 is welded on the elbow 2, and the table support 10 is connected with the straight pipe 9, and the straight pipe 9 is connected through the table support 10 pressure gauge 11. A handle 8 is mounted on the account head 7 . The retaining ring 5 and the Y-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com