A locking mechanism and a forging die using the locking mechanism

A locking mechanism and die technology, used in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc. problem, to achieve the effect of reliable locking state, automatic locking, and avoiding dependence on external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

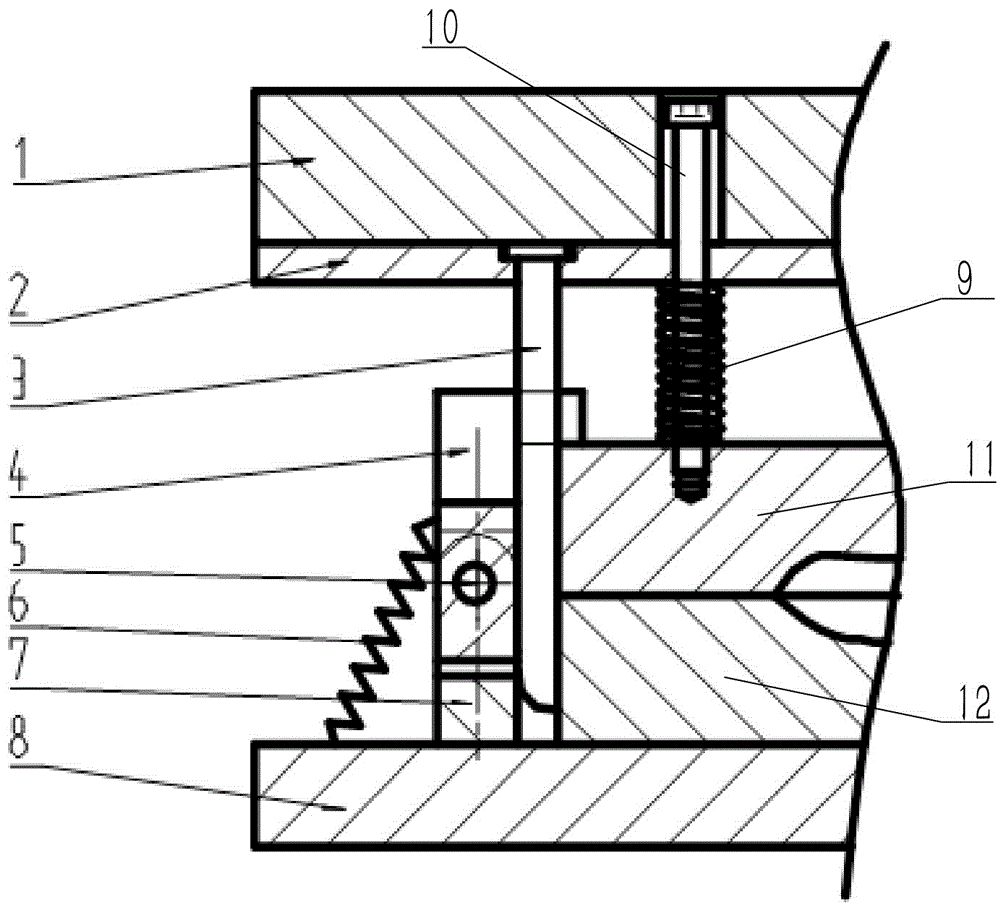

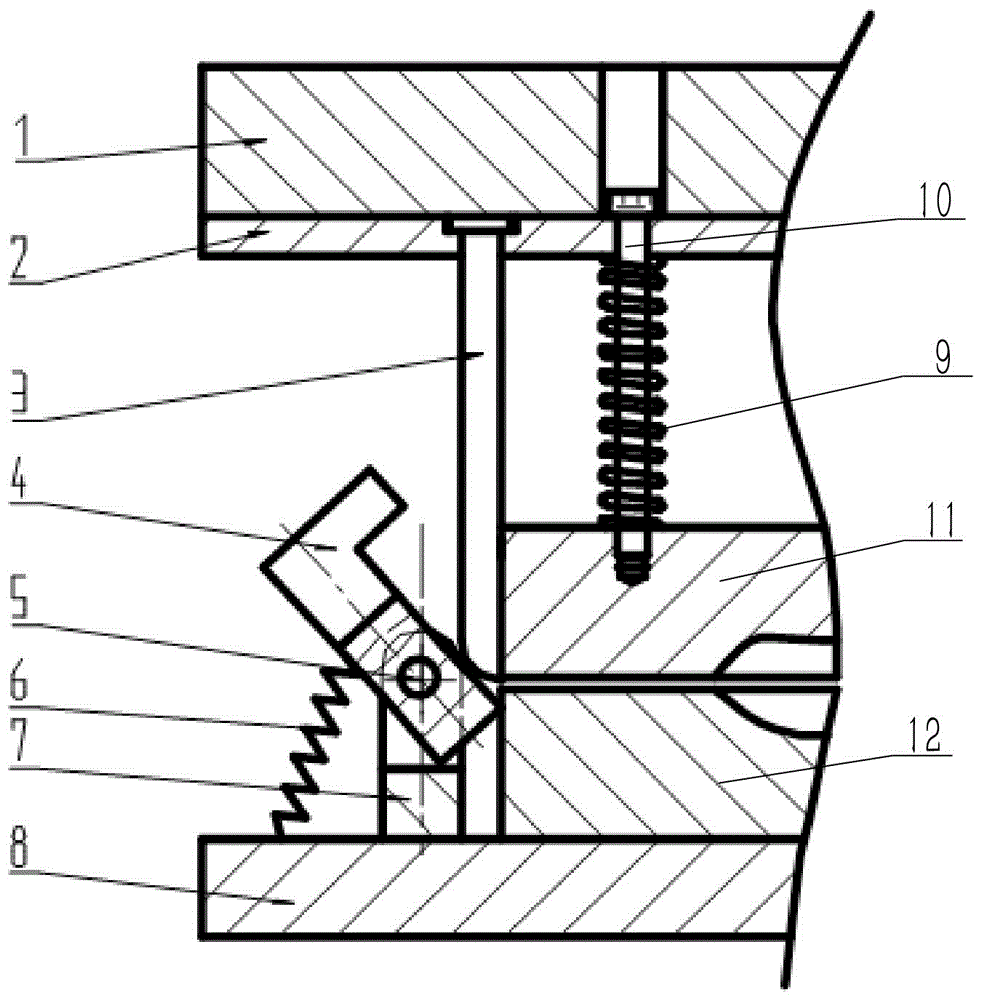

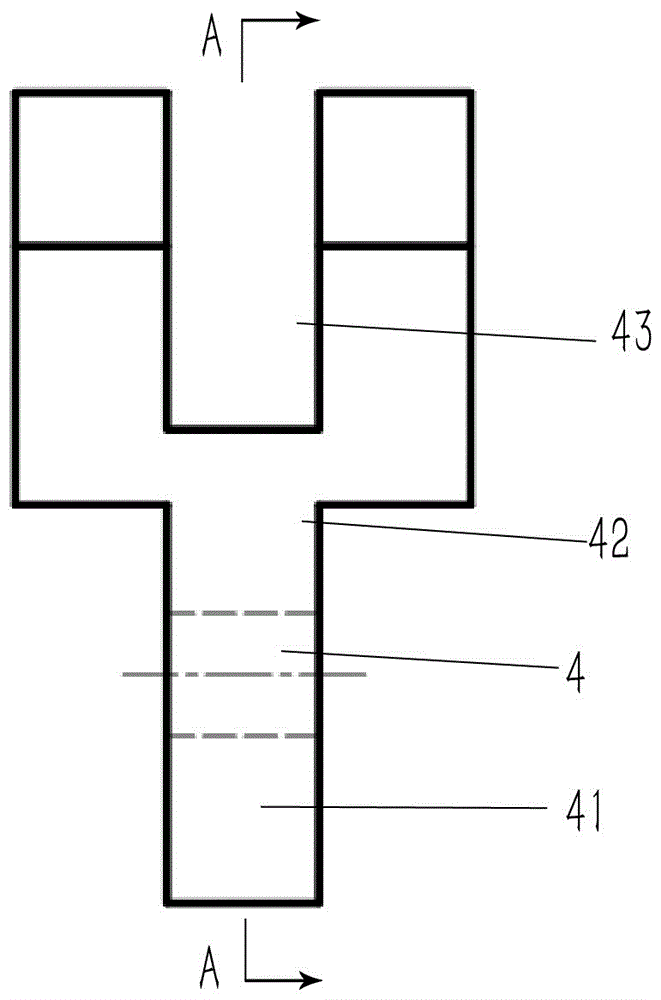

[0024] The embodiment of forging die among the present invention: as Figure 1 to Figure 6 As shown, the forging device is mainly composed of an upper mold, a lower mold and a locking mechanism, wherein the upper mold is composed of an upper template 1, a pressing plate 2, a guide rod 10 and an upper mold body 11, and the upper mold body 11 passes through the guide rod 10 The detachment is assembled under the pressure plate 2, and the outer circumference of the guide rod 10 is equipped with a top pressure spring 9 installed between the pressure plate 2 and the upper mold body 11; The edge portion of the upper body is vertically provided with a hinged seat spaced apart from the lower mold body 12, and the gap between the hinged seat and the lower mold body 12 is a downwardly recessed guiding channel. The locking mechanism includes a turning member 4 hinged on the hinge seat 7 through a hinge shaft 5, a push rod 3 fixed on the pressing plate 2, and a return spring 6 connected be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com