High precision light-cured resin molding 3 D (three dimensional) printer

A light-curing resin and 3D printer technology, applied in the field of 3D printers, can solve the problems of low light content, invisible product molding, waste of resin, etc., and achieve obvious technological progress, easy printing and separation, and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

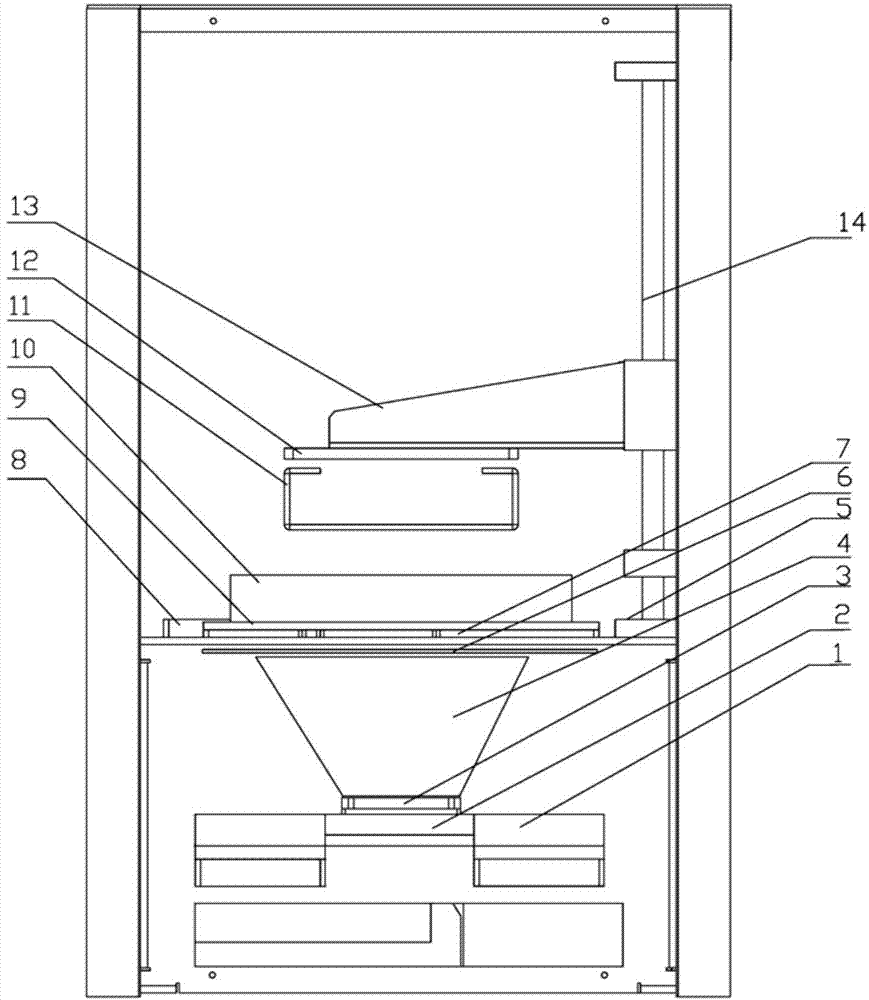

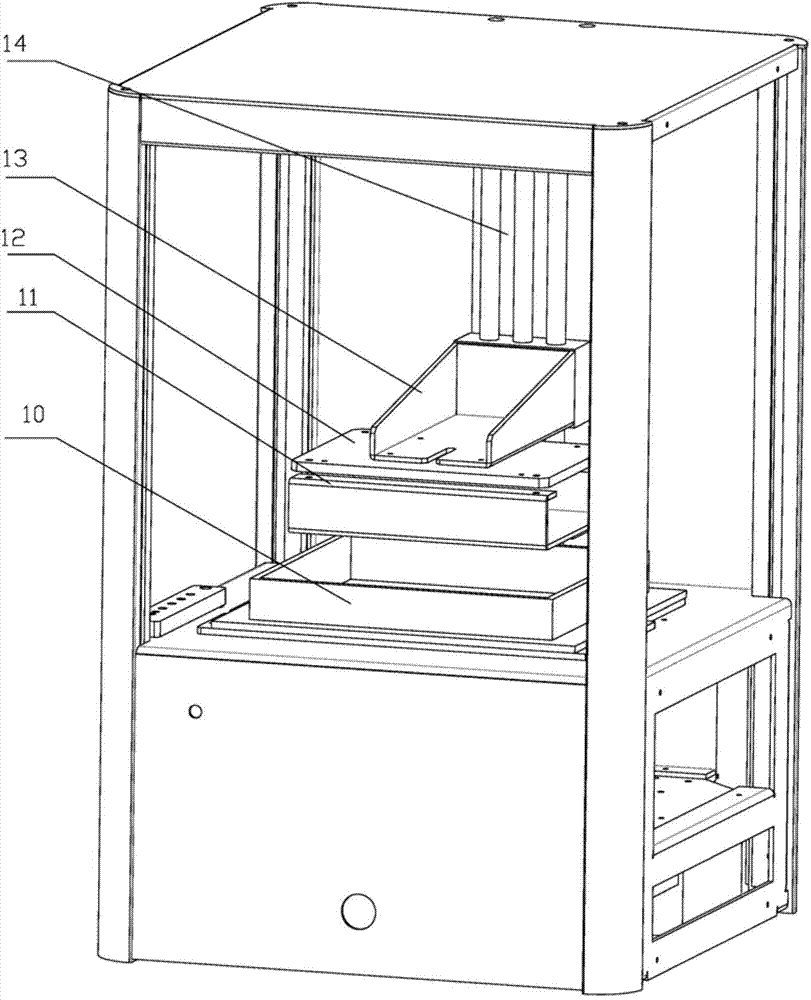

[0025] Embodiment 1: A 3D printer formed by high-precision light-cured resin. The printing size range of this printer is 160*110*200mm (length*width*height). The technical solution adopted is:

[0026] Including the LED light source 3, the power of the LED light source 3 is 200W, and the specification is 14 strings and 14 parallels. The bottom of the LED light source 3 is provided with a heat conduction unit 2 and a heat dissipation unit 1, the heat conduction unit 2 adopts a heat pipe or a heat plate, the heat dissipation unit 1 is provided with fins and a fan for heat dissipation, and the fan outlet is arranged at the bottom of the printer to exhaust air.

[0027] The LED light source 3 is an ultraviolet LED light source with a wavelength of 375-405NM, and a luminous flux 4 is arranged between the periphery of the LED light source 3 and the upper Fresnel lens 6; the luminous flux 4 adopts an aluminum alloy plate.

[0028] The area of the Fresnel lens 6 can cover the liquid...

Embodiment 2

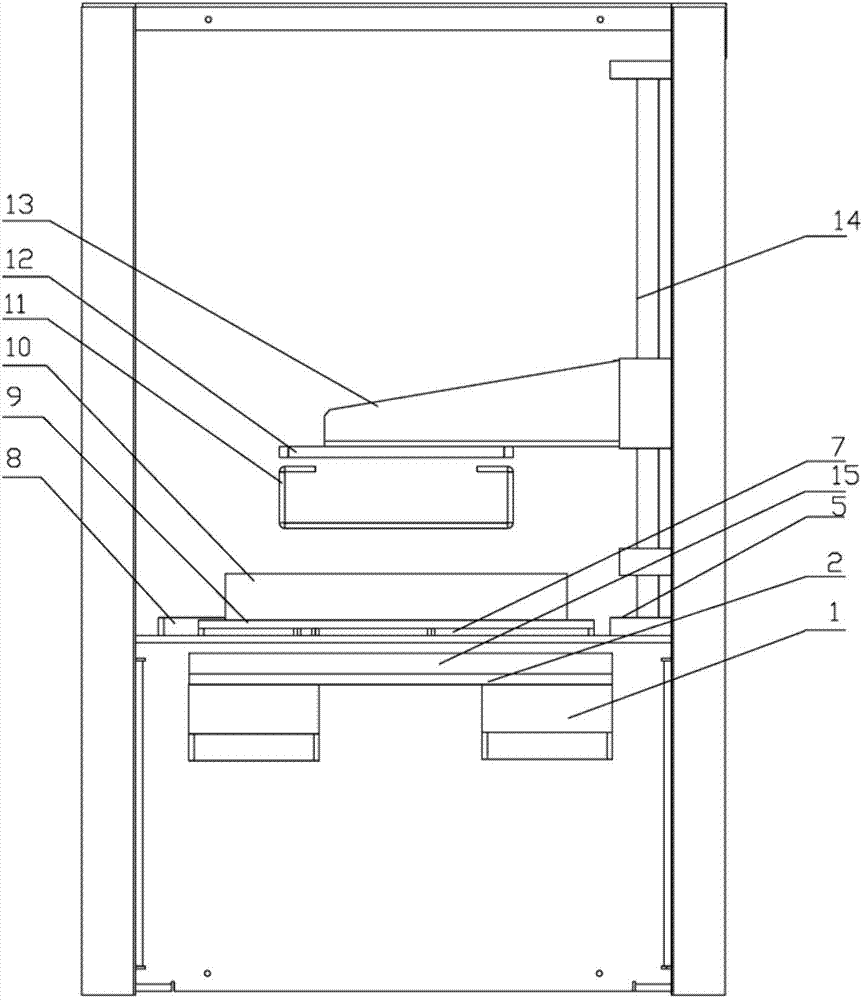

[0044] Such as image 3 As shown, as another embodiment, the light source of the present invention adopts a plane LED light board 15, and the area of the plane LED light board 15 is larger than that of the liquid crystal screen 7, and the distance between the two is about 10mm. The Fresnel lens is canceled, and the plane LED light board 15 The light from the light directly hits the liquid crystal screen 7, and in this embodiment, there is basically no light spots, no dark corners are formed, the light loss is small, and the printing accuracy is improved. The heat dissipation of the flat LED light board 15 adopts the heat conduction unit 2 and the heat dissipation unit 1 , and the heat conduction unit 2 adopts a high-efficiency heat plate to dissipate the heat of the plane LDE light board 15 and the liquid crystal screen 7 . The planar LDE light plate 15 selects an ultraviolet light source with a wavelength of 375-405NM.

Embodiment 3

[0046] As another embodiment, the printing platform 11 is a hollow or solid structure, its side view is a rectangular structure, the upper surface is a whole plane, and the bottom plate of the printing platform 11 is also a whole plane, which is used for bonding the printed product top. The upper surface of the printing platform 11 is provided with 4 pull-up threaded holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap