A vehicle and its active lateral stabilizing device

A technology of a lateral stabilizer and a stabilizer bar, which is applied to vehicle components, transportation and packaging, interconnection systems, etc., can solve the problems of large roll angle, increase the torsional stiffness of the stabilizer bar, increase the cost, etc., and reduce the vibration of the roll angle. , Provide the effect of ride smoothness and large anti-rolling moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

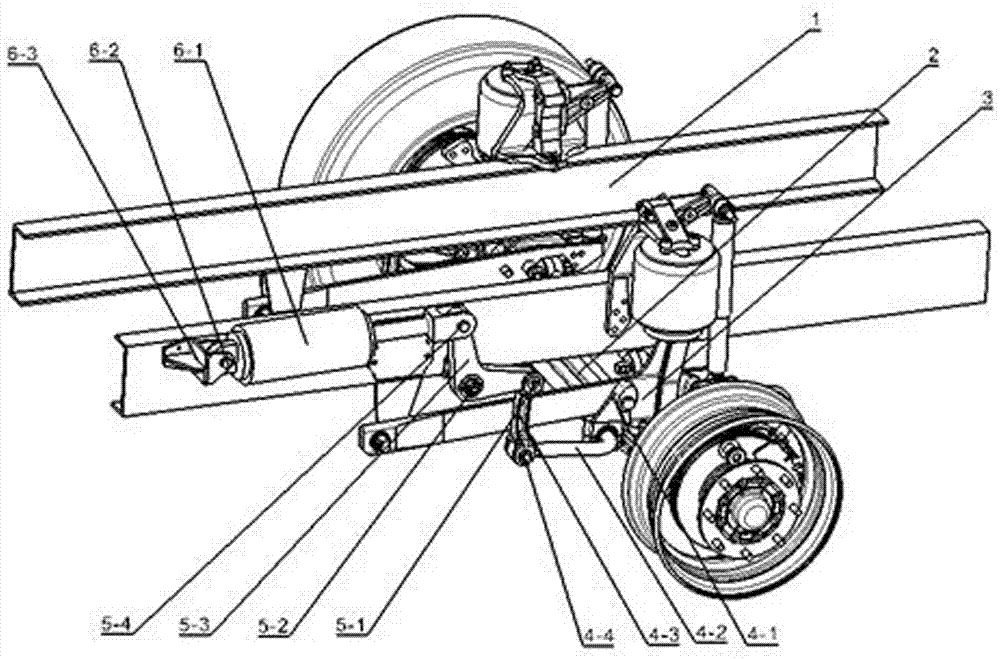

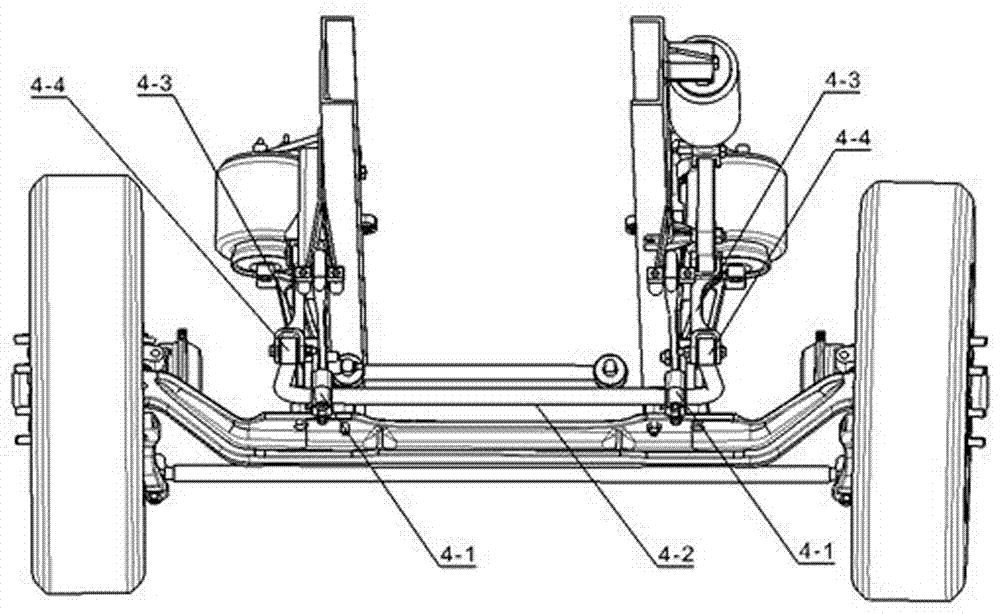

[0015] An example of a vehicle such as Figure 1~2 Shown: including body 1, suspension 3 and active lateral stabilization device arranged between the body and suspension, axle 2 is arranged at the lower end of suspension 3, and active lateral stabilization device includes a lateral stabilizer bar arranged on suspension 3 4-2 and the drive devices respectively arranged at both ends of the stabilizer bar. The stabilizer bar is a complete U-shaped bar structure. Each drive device includes a power output piece. The drive device is connected with the corresponding end of the stabilizer bar to drive The torsion power output end of the stabilizer bar. The two driving devices at both ends of the stabilizer bar have the same structure. Only one of the driving devices will be described in detail. The driving device includes a power output crank arm whose rotation axis extends laterally. The power input crank arm is fixed on the top, and the power output crank arm and the power input cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com