Patents

Literature

36results about How to "Increase the twist angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

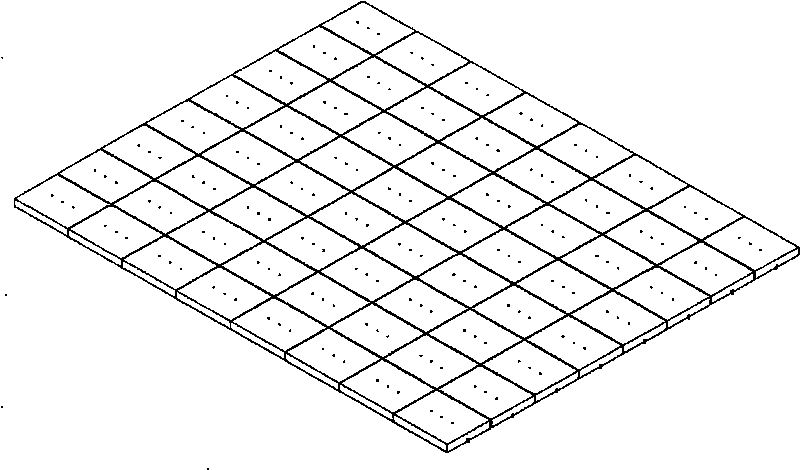

Micro reflector array manufacturing method

ActiveCN101718906AIncrease the effective areaReduce the effective areaOptical elementsEtchingFill factor

The invention discloses a micro reflector array manufacturing method which is used for manufacturing micro reflector array with high fill factors, big-angle torsion and big array. The method adopts bulk-silicon MEMS processing technology, a vertical comb driving mode, wafer bonding technology and etching technology and is characterized in that the wafer is bonded after a middle driver layer is processed, a layer of reflector surface is covered above the driver layer; on the basis, a special deep etching release technology is adopted to release a shore reserved in the driver layer to realize micro reflector torsion, thus realizing the purpose of driving with high fill factors, big-angle torsion and low voltage.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

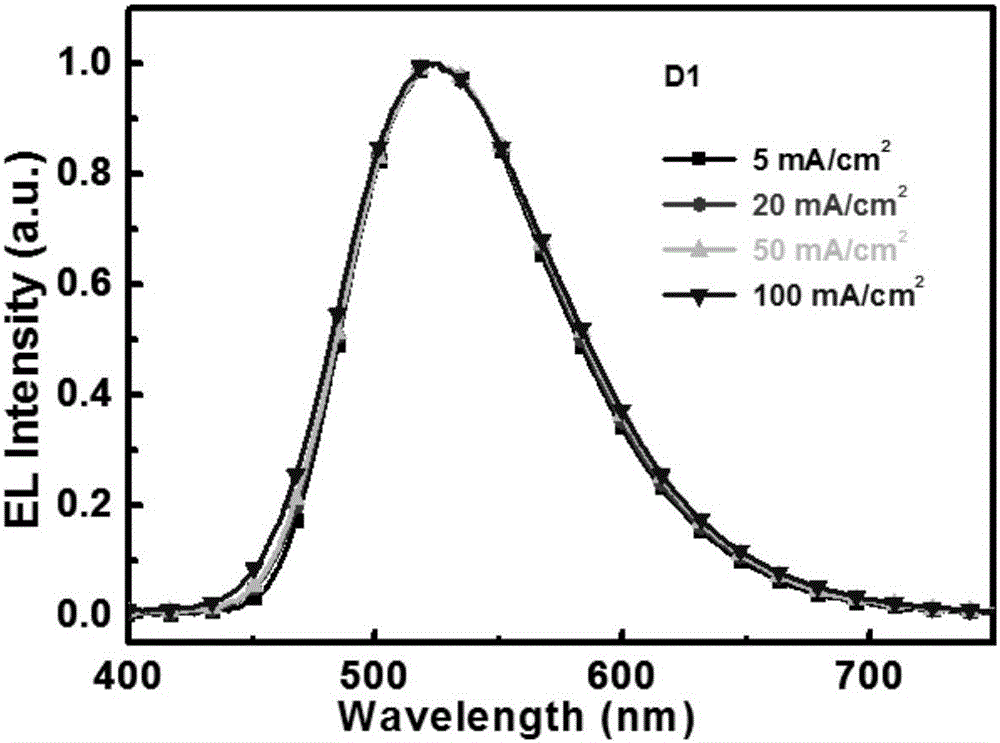

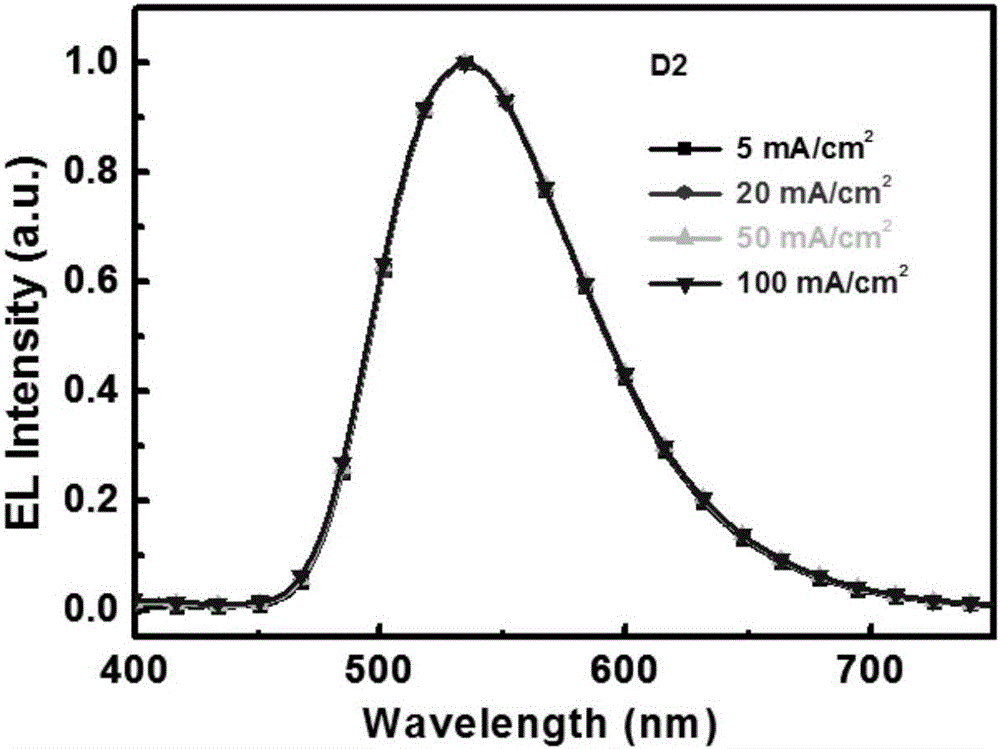

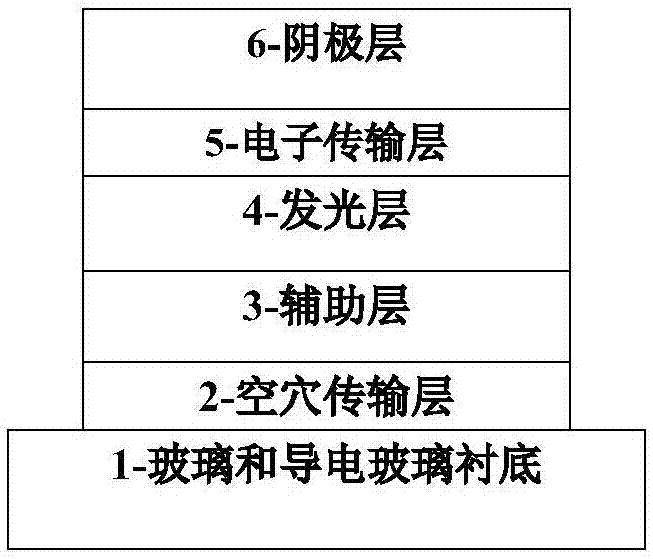

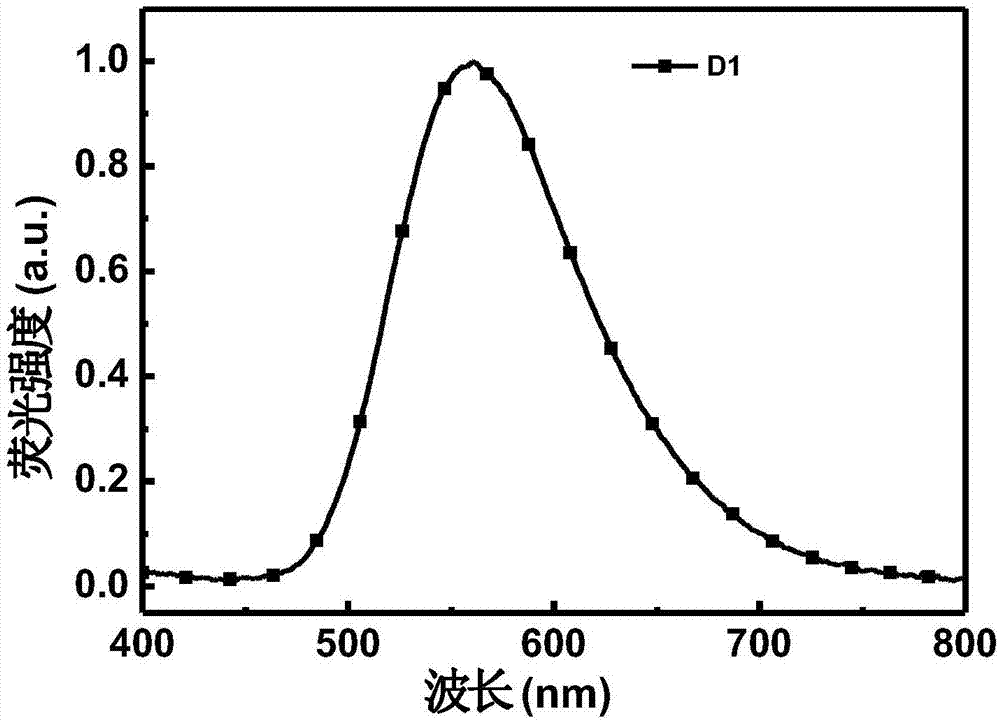

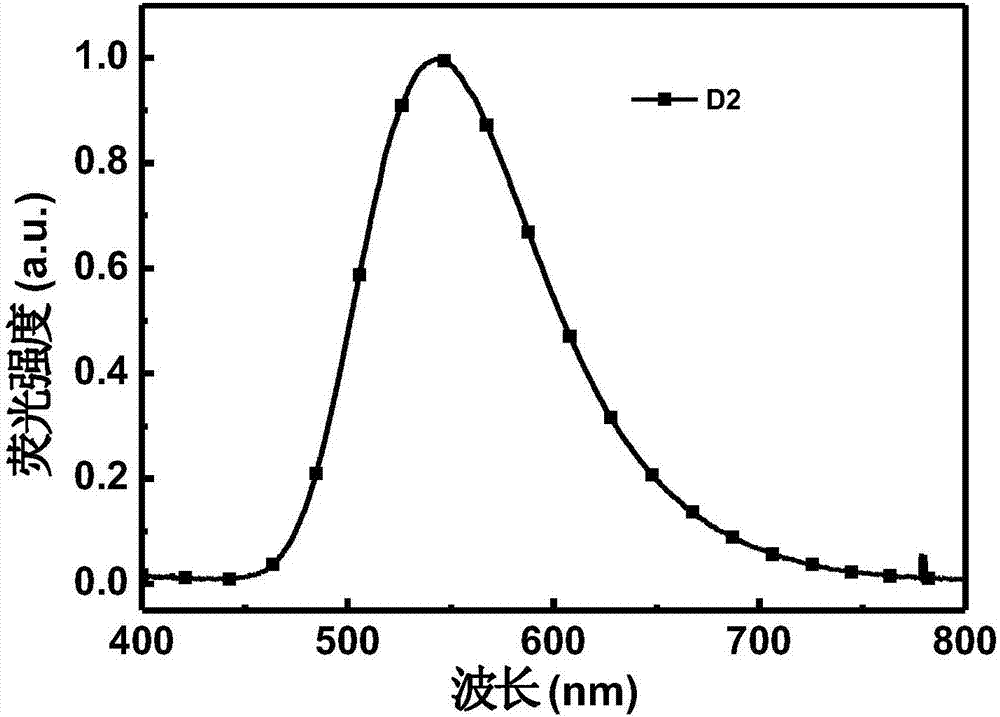

Thermal activation delayed fluorescence material containing 1, 10 phenanthroline unit and application of material

InactiveCN105859714AIncrease the twist angleHigh RISC speedGroup 4/14 element organic compoundsSolid-state devicesFluorescencePhenanthroline

The invention provides a thermally-induced delayed fluorescence material and a preparation method of an organic electroluminescent device. The preparation method includes: using 1, 10 phenanthroline which is rigid as a strong-pull electron centronucleus and a diphenylamine derivative with high electron donating capability as a peripheral connecting group to form a D-A-D strong charge transfer state compound, wherein R1, R2 R3, R4, R5, R6, R7 and R8 are one of aromatic diphenylamine derivatives. The thermal activation delayed fluorescence material is simple to prepare and suitable for wide application. An organic compound obtained by the material can serve as a luminous layer material in OLEDs, and luminous efficiency and stability of the electroluminescent device can be improved by doping proper main materials.

Owner:WUHAN UNIV

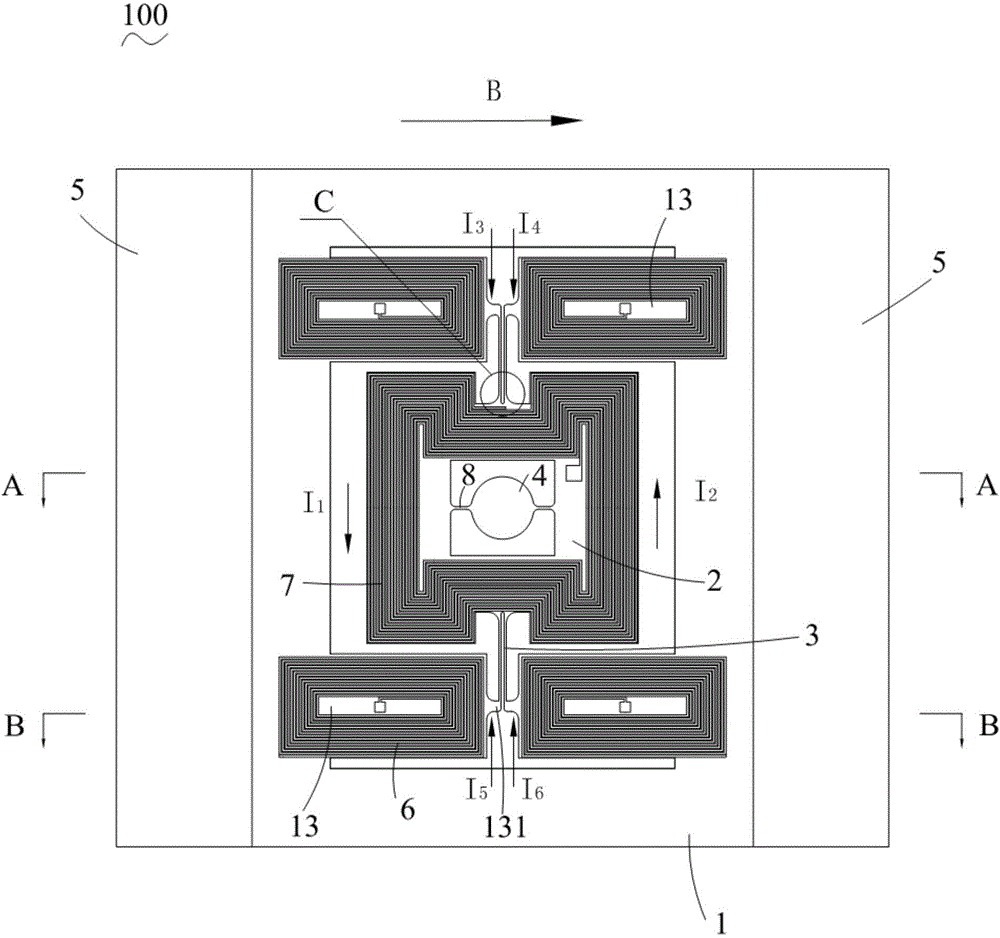

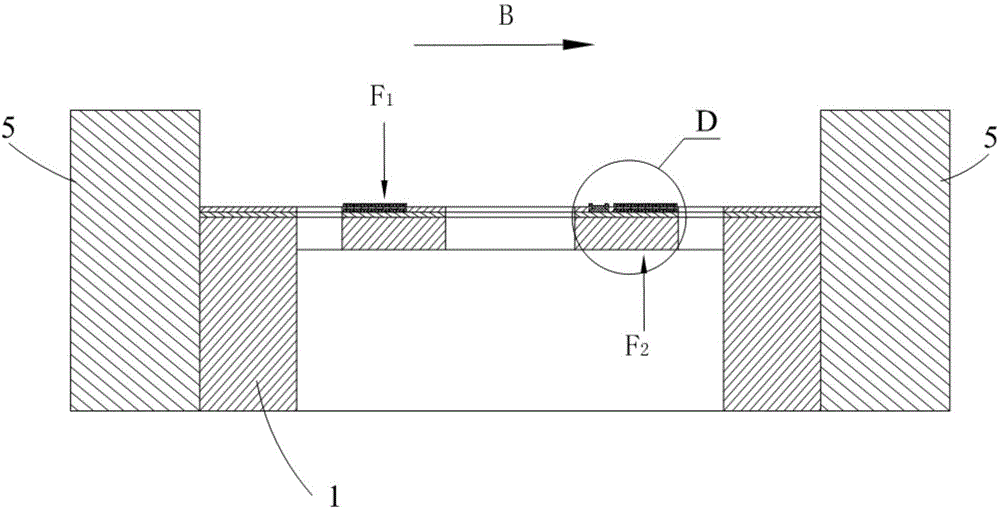

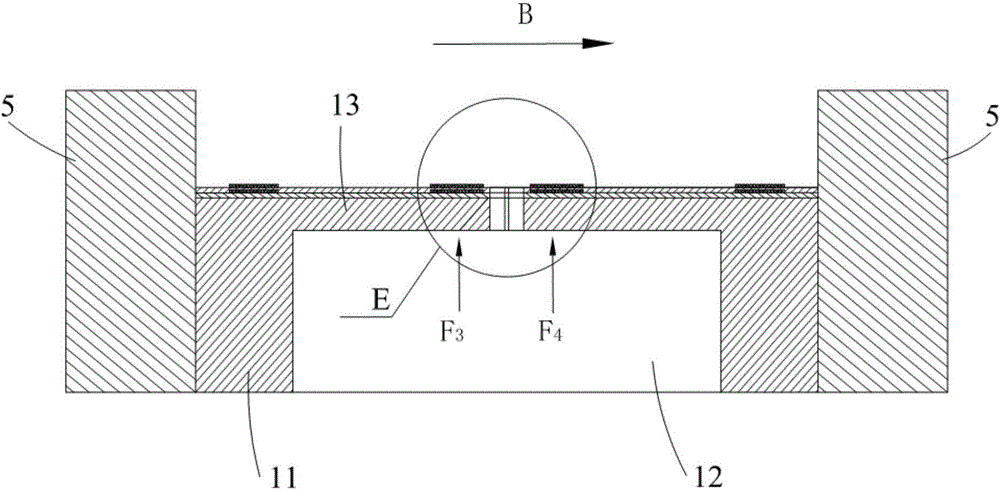

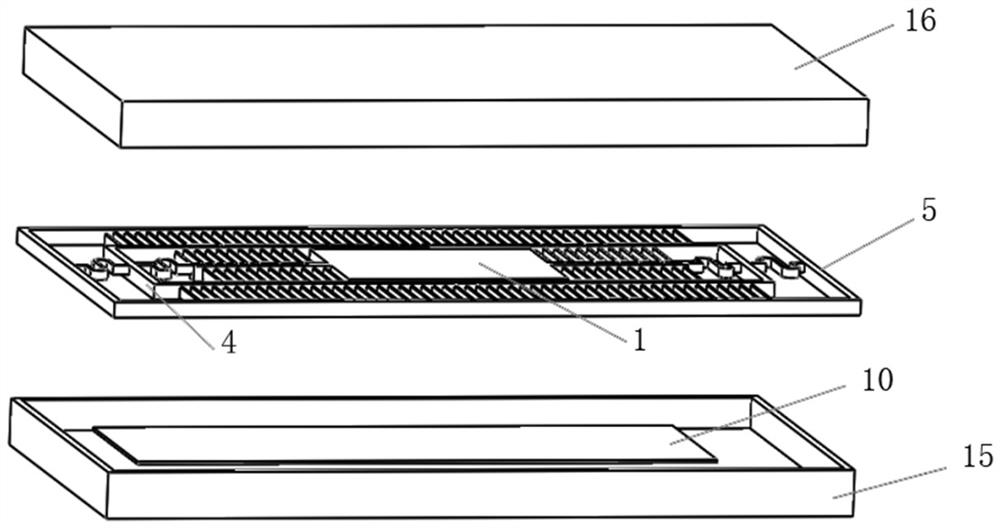

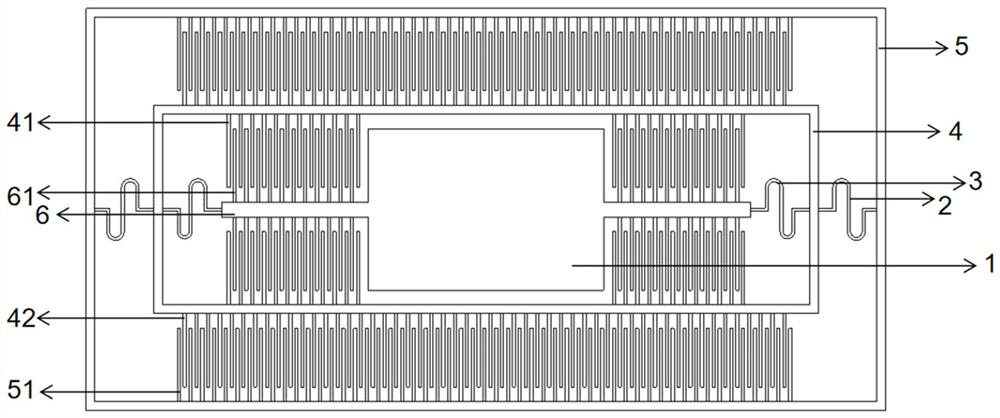

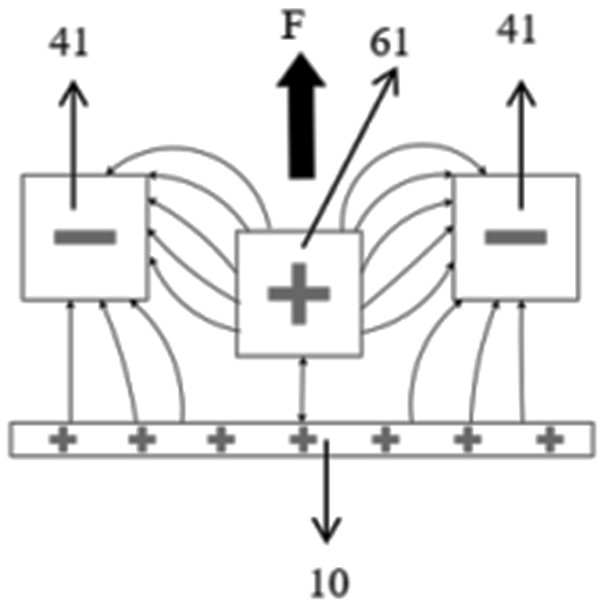

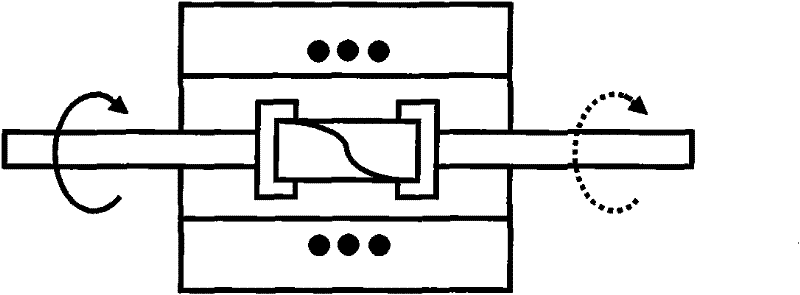

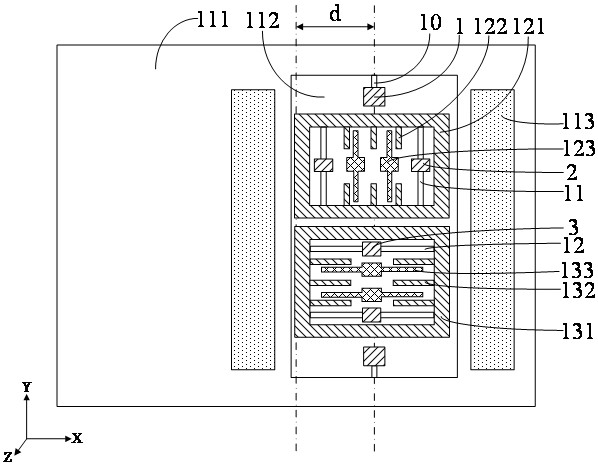

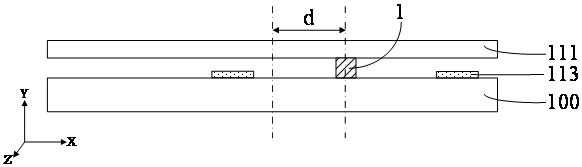

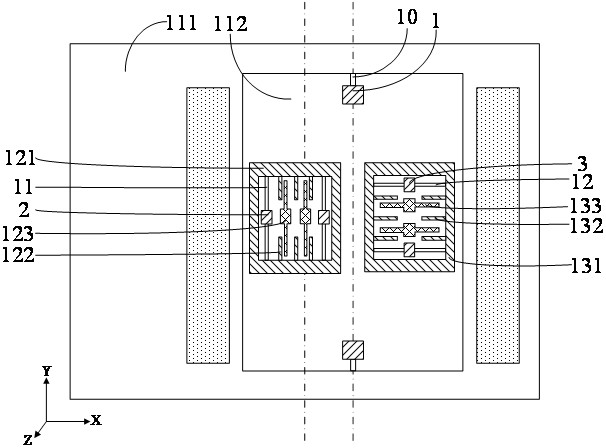

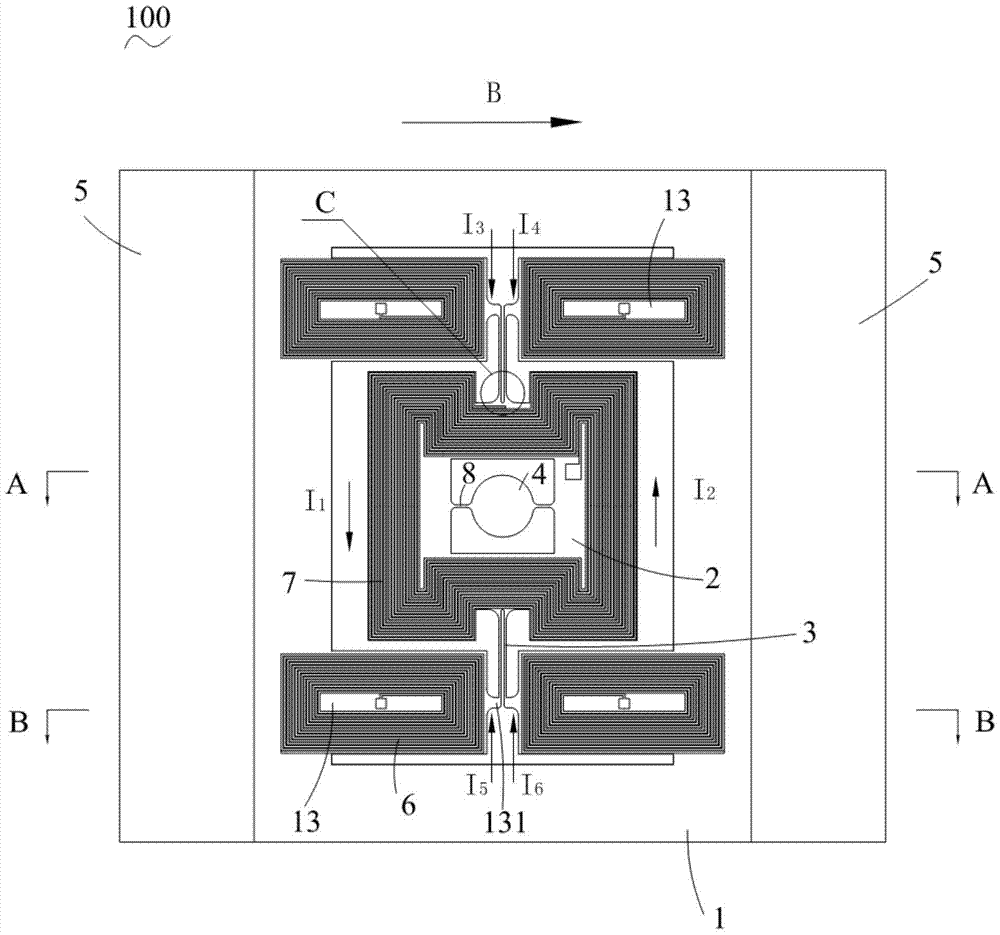

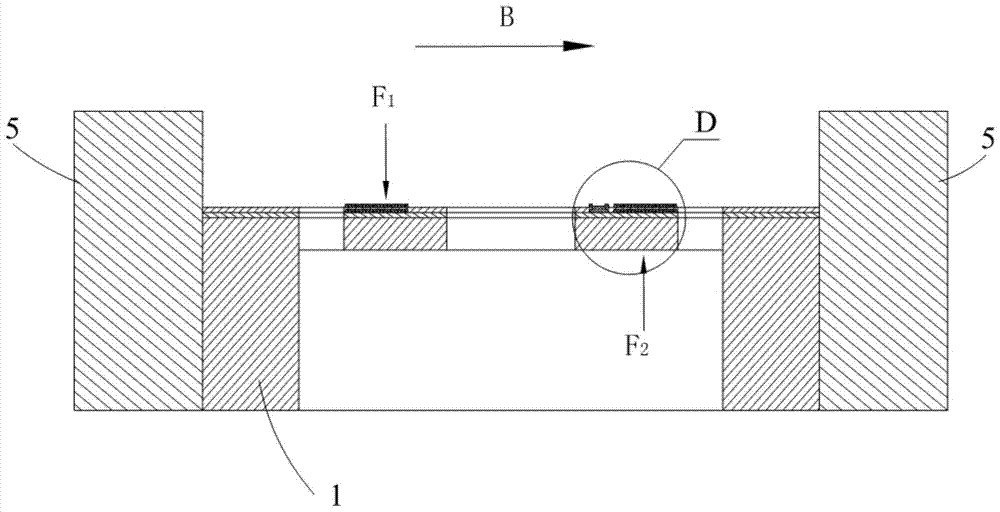

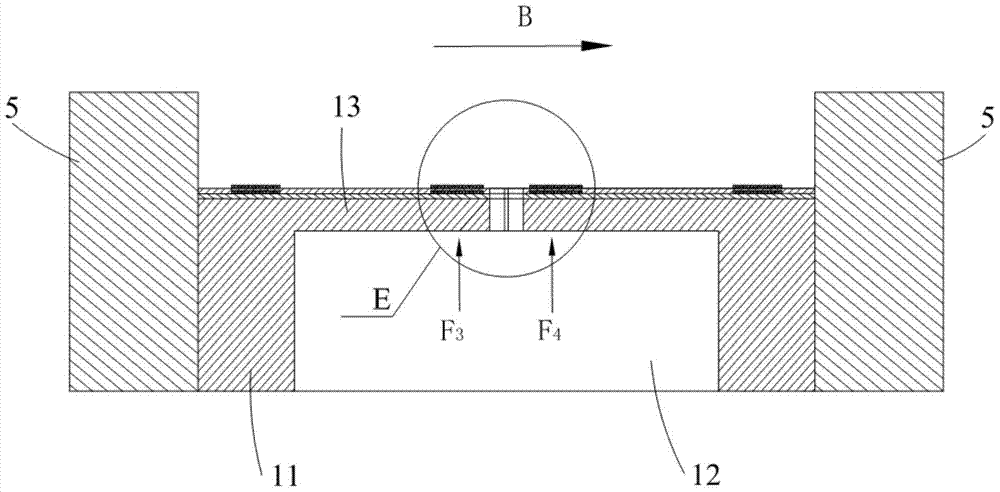

Electromagnetic drive two-dimensional scanning micro mirror for laser scanning display

ActiveCN104597596AReduce mutual interferenceIncrease the twist anglePiezoelectric/electrostrictive devicesFlexible microstructural devicesPower flowLaser scanning

The invention relates to an electromagnetic drive two-dimensional scanning micro mirror for laser scanning display. The micro mirror comprises a peripheral frame, an inner frame arranged in the peripheral frame, a vertical scanning twist beam connecting the peripheral frame and the inner frame, a micro reflecting mirror arranged in the inner frame and a pair of magnets. The peripheral frame is provided with a cantilever; the inner frame is connected to the cantilever of the peripheral frame through the vertical scanning twist beam; the cantilever is provided with a cantilever drive coil, the inner frame is provided with an inner frame drive coil, the magnets are arranged on two sides of the cantilever oppositely, and the magnetic induction lines produced by the magnets are perpendicular to the current directions of the cantilever drive coil and inner frame drive coil after powering. According to the micro mirror, the two groups of drive coils scanning in two directions are controlled independently, interference between two directions is reduced, large twisting angle can be acquired easily, the magnetic field utilization rate can be increased, and the drive scheme is simplified.

Owner:苏州工业园区纳米产业技术研究院有限公司

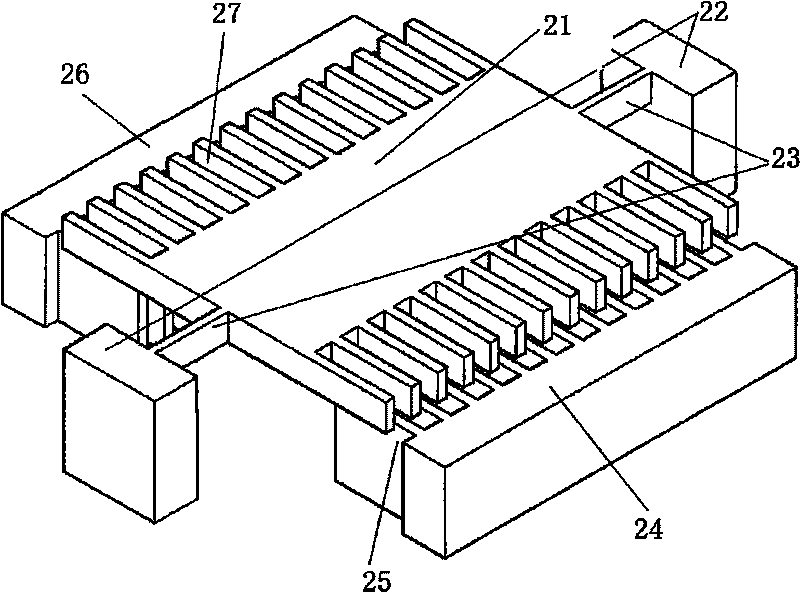

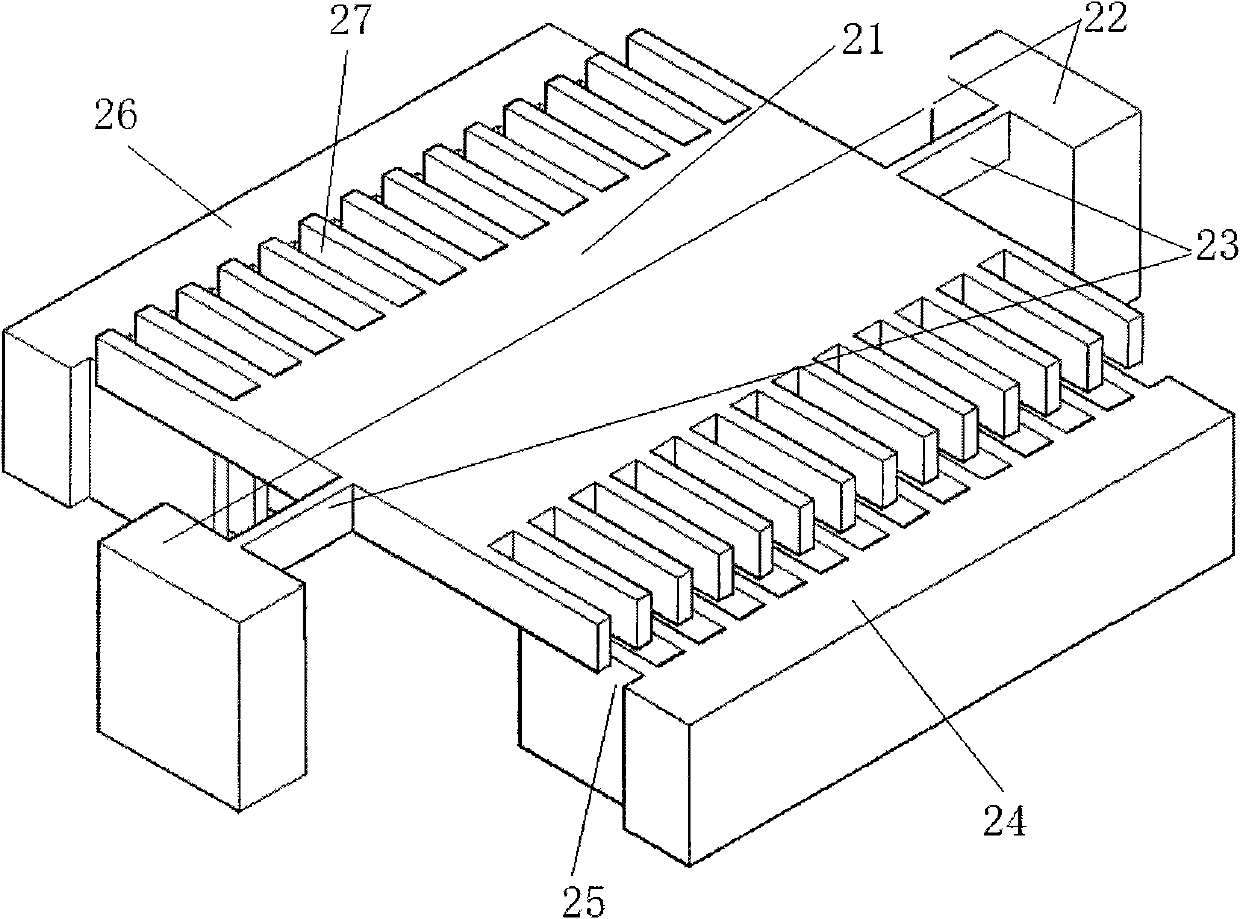

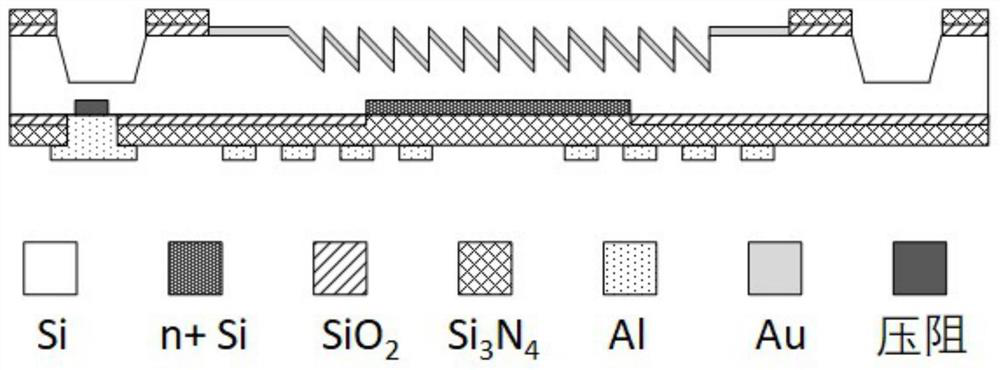

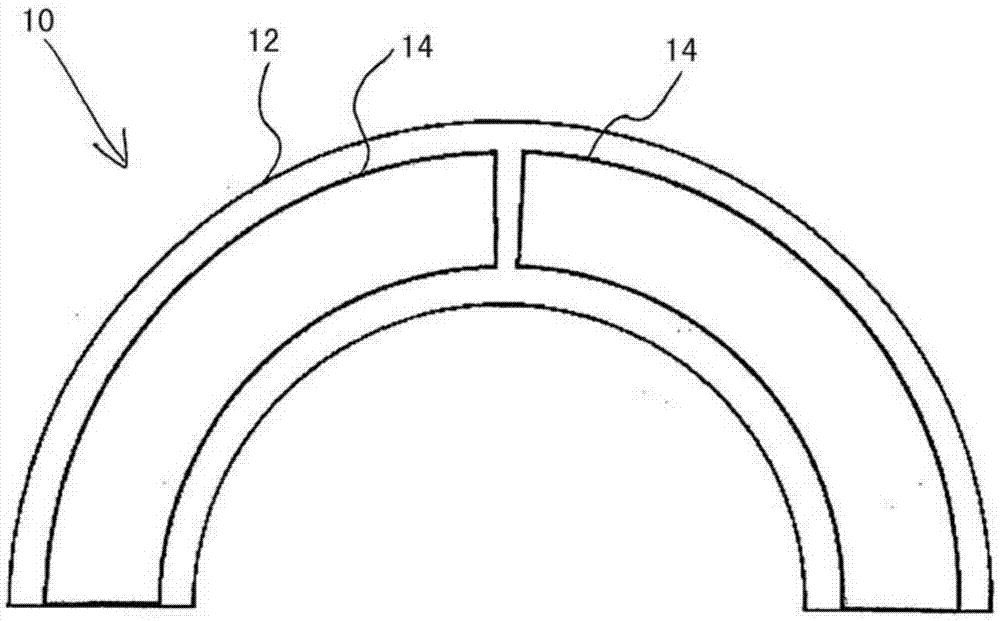

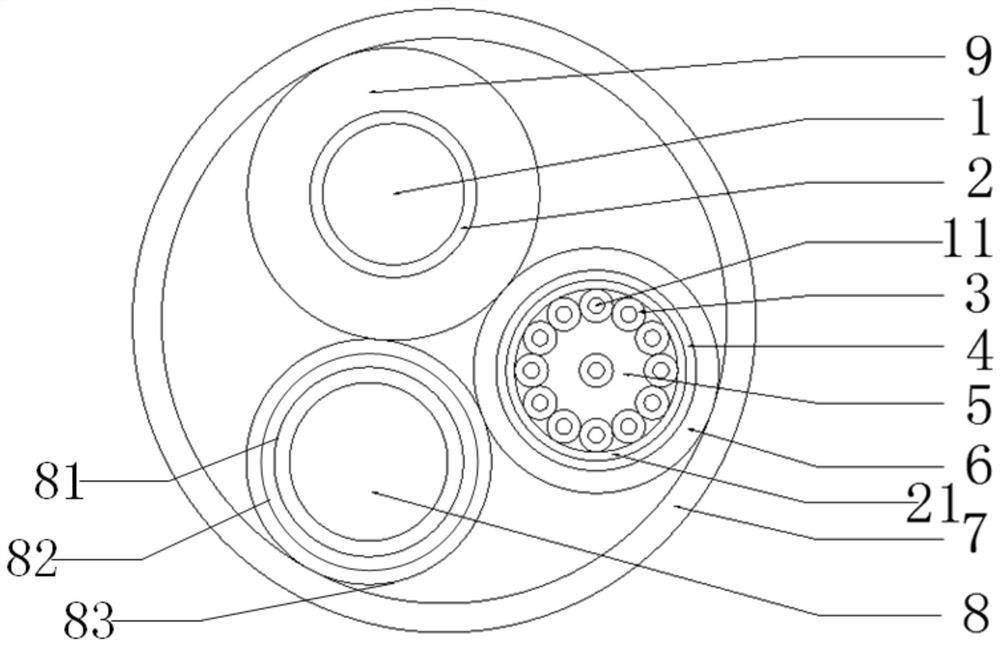

Double-layer comb tooth driving MEMS scanning mirror for laser radar and preparation method

ActiveCN111856430AAchieve maximum deflection angleSmall sensitive shaft stiffnessTelevision system detailsWave based measurement systemsGlass coverEngineering

The invention relates to the technical field of micro electro mechanical systems, in particular to a double-layer comb tooth driving MEMS scanning mirror for a laser radar and a preparation method. The MEMS scanning mirror comprises a transparent glass cap, a rotary scanning mirror body and a silicon substrate. The rotary scanning mirror body comprises a square micro mirror, a first S-shaped torsion beam, a second S-shaped torsion beam, a rectangular inner-layer frame and a rectangular outer-layer frame; the outer-layer frame is coaxially arranged outside the inner-layer frame in a sleeving mode, and the two ends of the inner-layer frame are connected with the outer-layer frame through first S-shaped torsion beams respectively; the two ends of the micro mirror are correspondingly connectedwith the inner-layer frame through a straight connecting beam and a second S-shaped torsion beam in sequence, so that the micro mirror is movably mounted in the middle of the inner-layer frame; and driving voltage is applied to the comb tooth electrode layer, the upper electrode and the lower electrode, so that the micro mirror can rotate in the movable cavity. According to the preparation method, the bulk silicon processing technology and the SOI-based silicon-glass bonding technology are adopted to complete manufacturing and packaging of the MEMS scanning mirror, the processing efficiency is high, and the repeatability is high.

Owner:HEFEI UNIV OF TECH

Fluorescent material containing beta-diketone structure as well as preparation method and application thereof

ActiveCN107445913AOvercome longevityOvercome the shortcomings of weak solid-state luminescenceSilicon organic compoundsSolid-state devicesSorbentElectron donor

The invention relates to a fluorescent material which has thermal activation delayed fluorescence and an excited state proton transfer property simultaneously. A D-pi-A-pi-D type strong charge transfer state compound is formed by taking beta-diketone or a derivative thereof with the excited state proton transfer property as a strong pull electron central nucleus (Acceptor), an amine derivative (Donor, D) with a strong electron donating ability as an electron donor and a benzene ring or other aromatic rings as a bridging group. The fluorescent material provided by the invention is simple to prepare and suitable for wide application. Therefore, the organic compound prepared by the invention can replace a conventional thermal activation delayed fluorescent material and an excited state proton transfer material and has important application value and wide prospect in the fields of fluorescence imaging, biosensing, ultraviolent adsorbents, light-emitting apparatuses and the like.

Owner:WUHAN UNIV

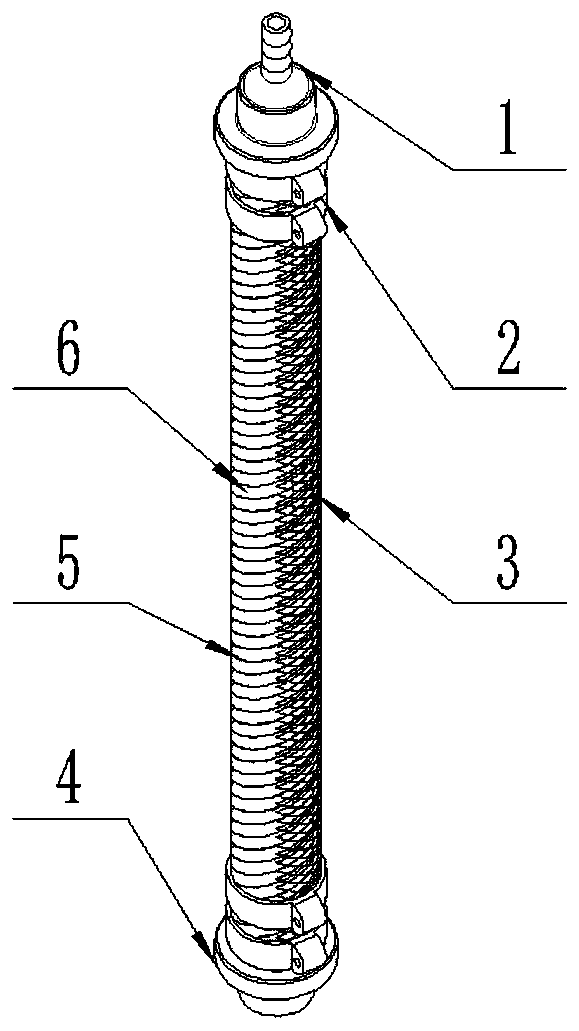

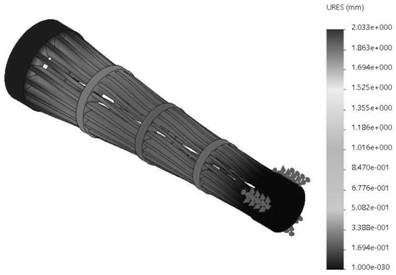

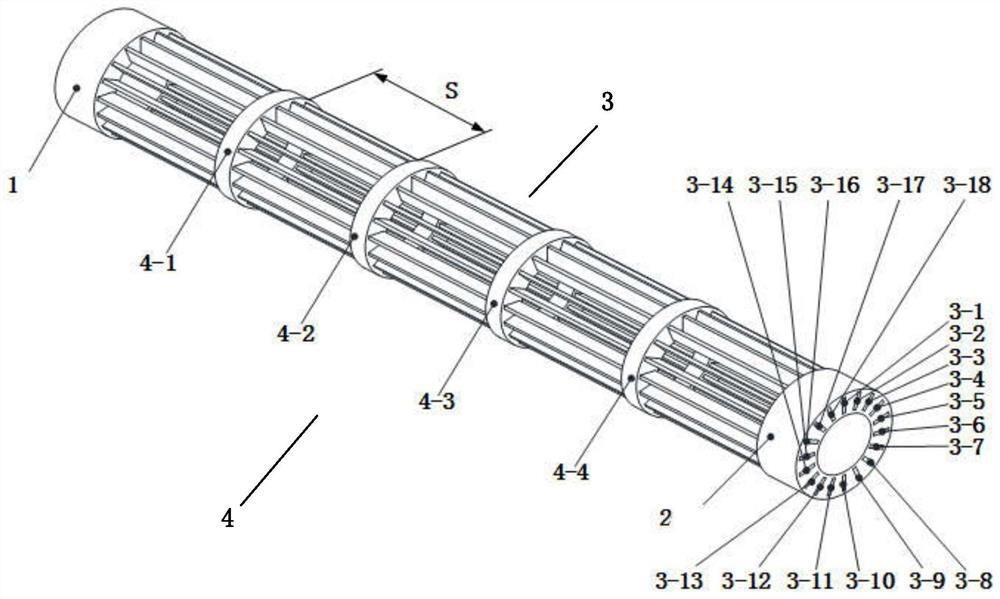

Torsional contraction artificial muscle

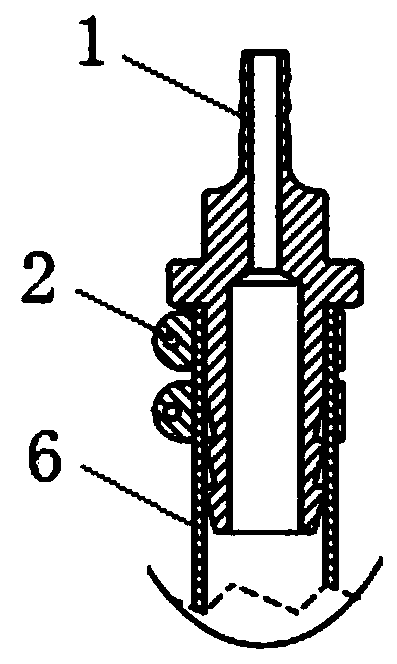

PendingCN110877331ABroad application prospectsSimple structureProgramme-controlled manipulatorRobotic rehabilitationManufacturing engineering

The invention relates to a soft driver, in particular to a torsional contraction artificial muscle. The torsional contraction artificial muscle comprises an outer packaging layer, a fiber winding andan elastomer, wherein the elastomer is of a hollow structure, and radial expansion and axial contraction are achieved by filling the driving medium into a hollow cavity; the fiber winding is arrangedon the outer surface of the elastomer, the fiber winding is of a spiral structure, and the elastomer is driven to twist through the spiral torsion drive; and the outer packaging layer is arranged on the outer side of the elastomer in a sleeving manner and is used for limiting the axial extension of the elastomer, and can axially contract and radially expand along with the elastomer. The torsionalcontraction artificial muscle is simple in structure and low in preparation cost, is not only suitable for hydraulic driving, but also suitable for pneumatic driving, can provide torsional movement and contraction motion and can be applied to different fields such as pipeline robots and rehabilitation devices.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

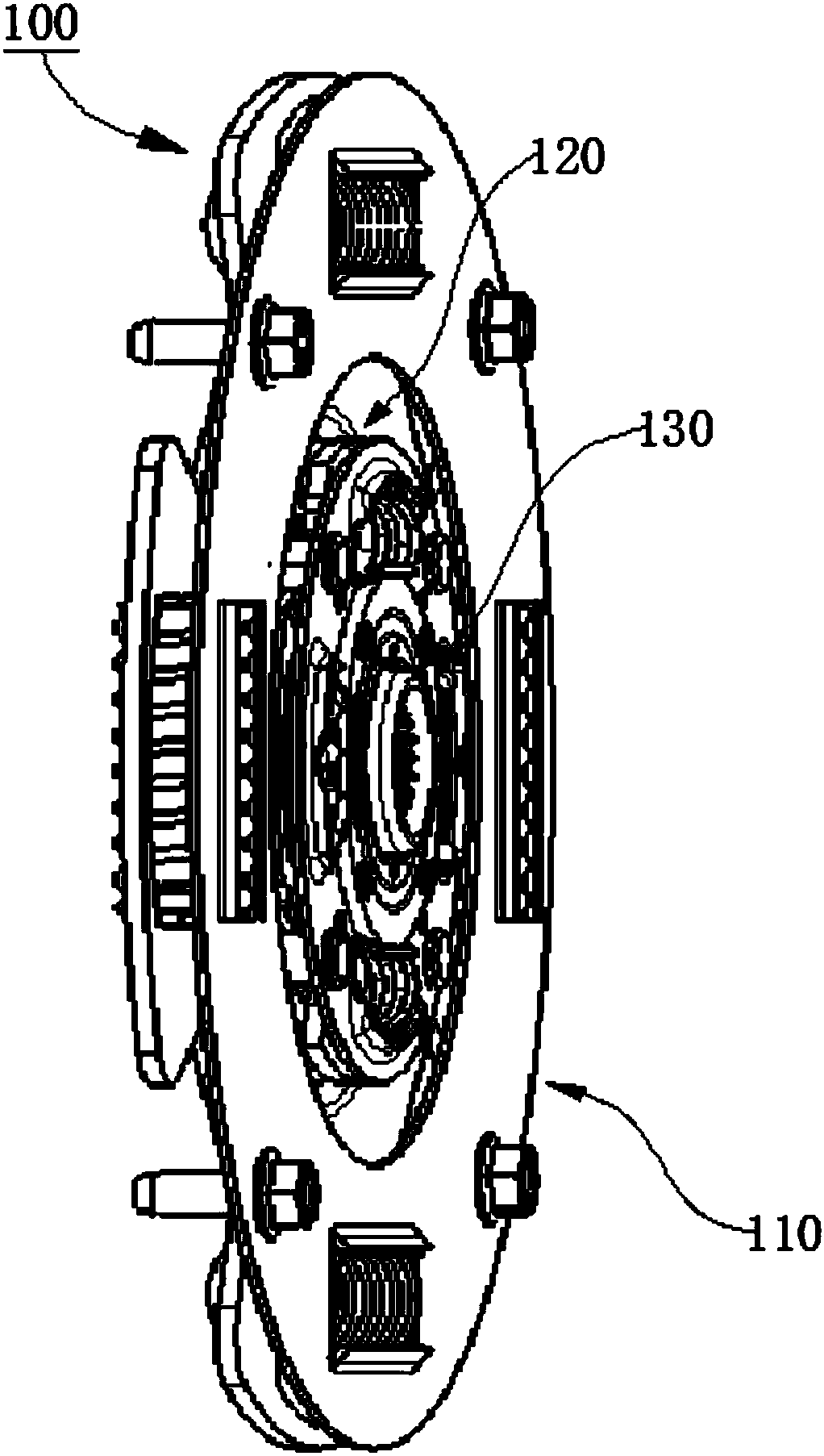

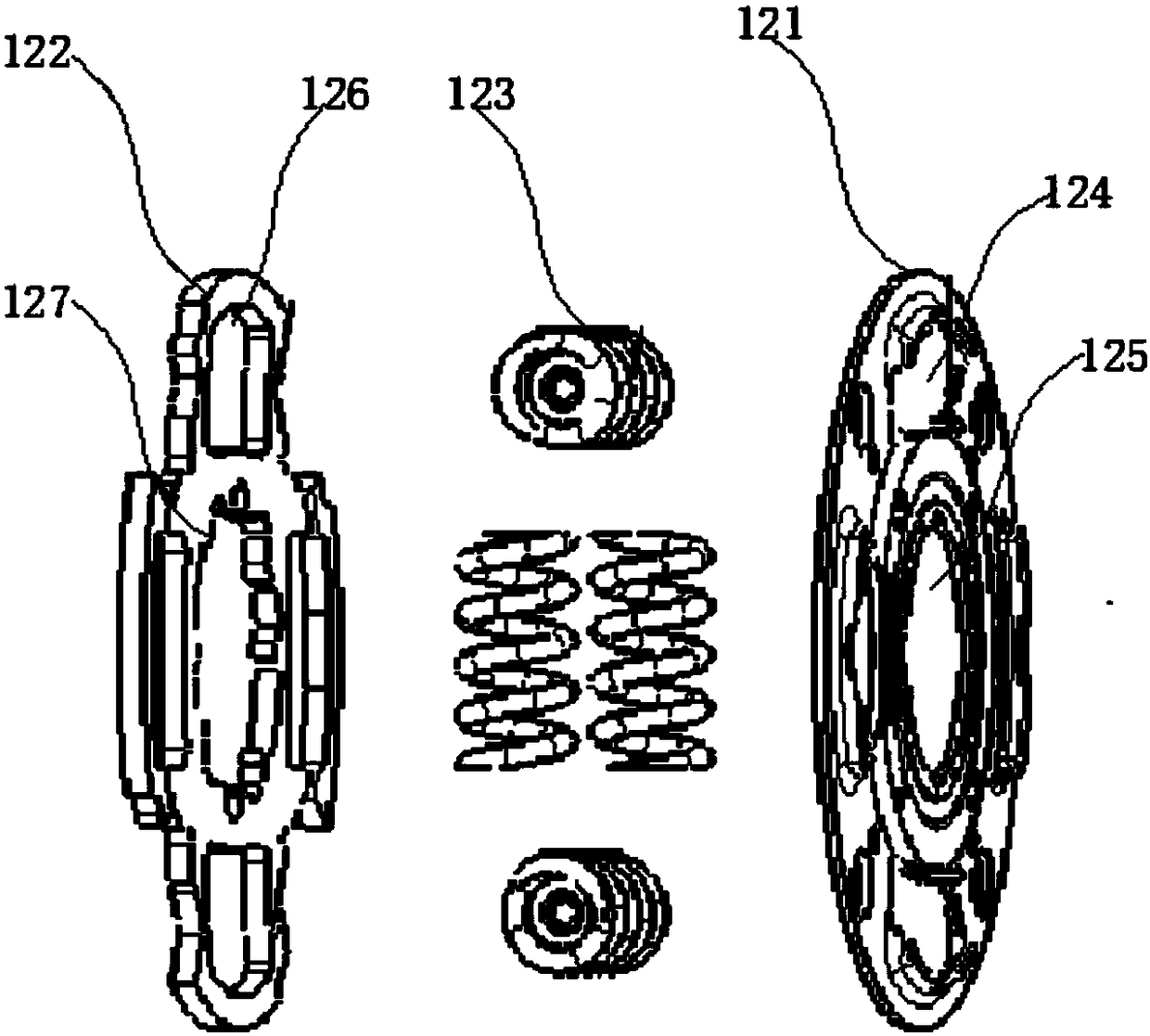

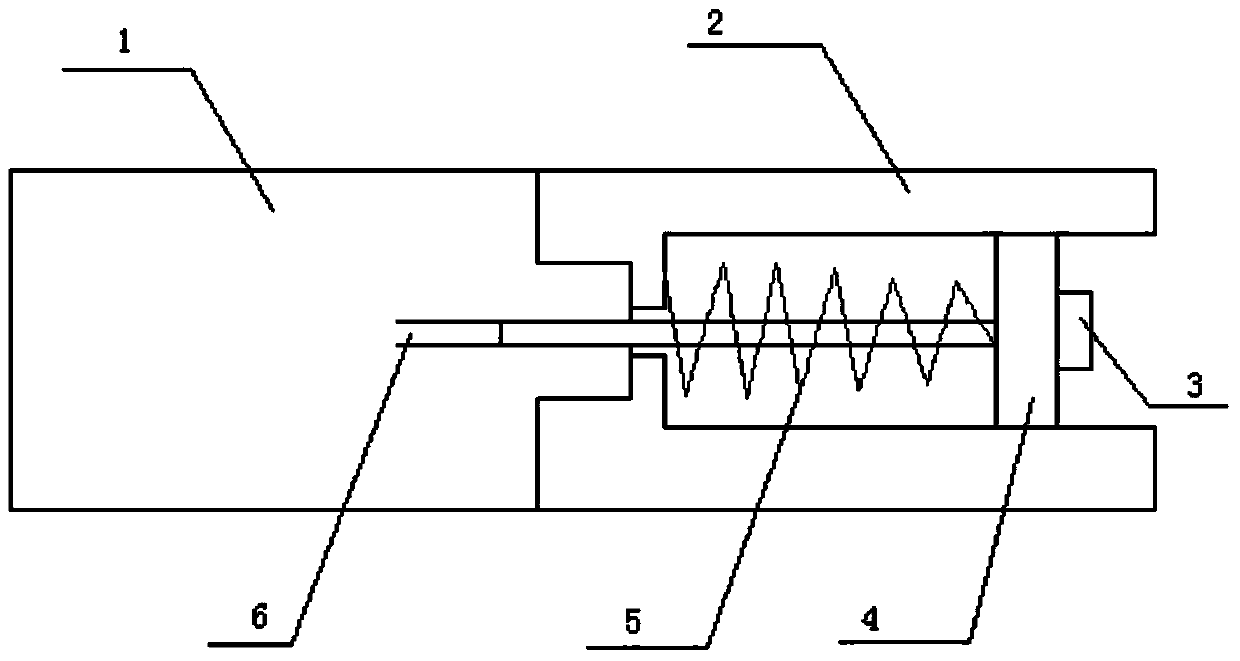

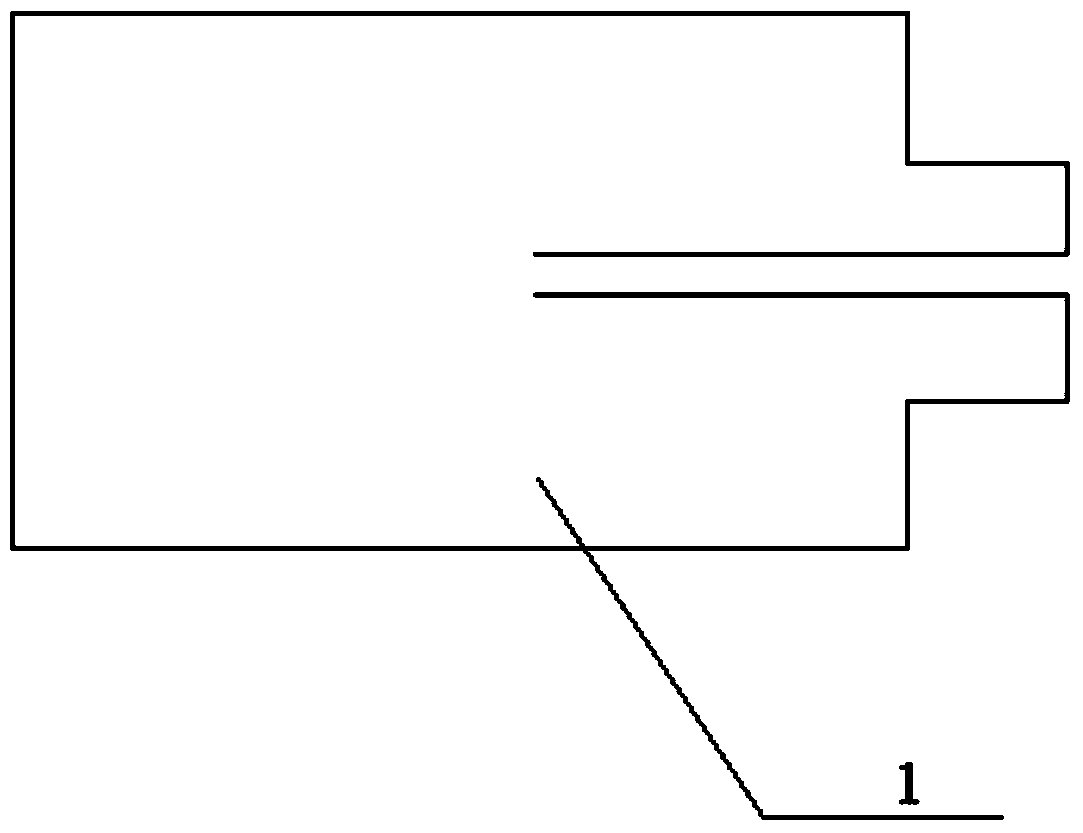

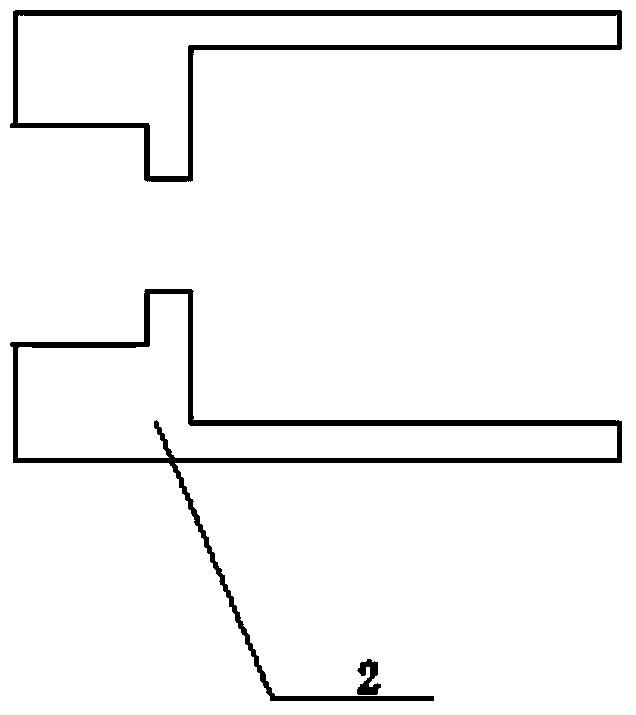

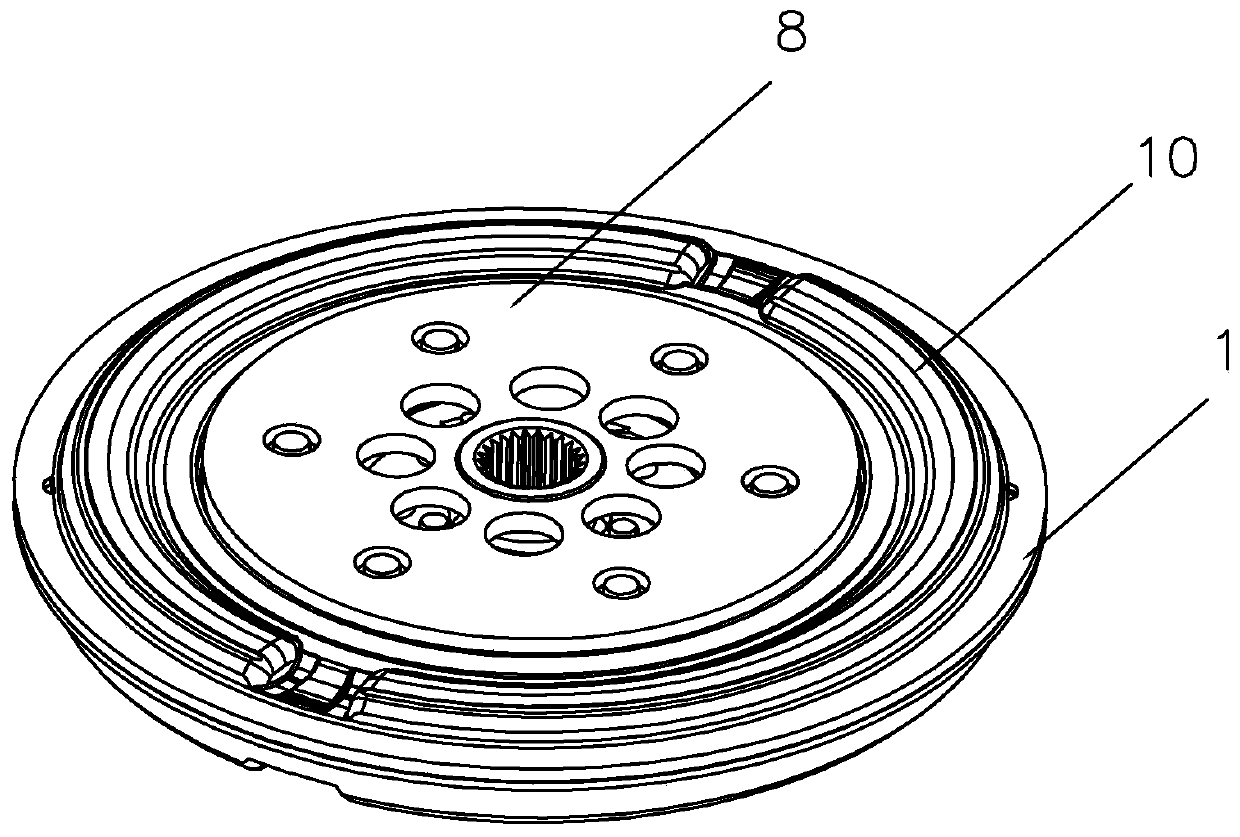

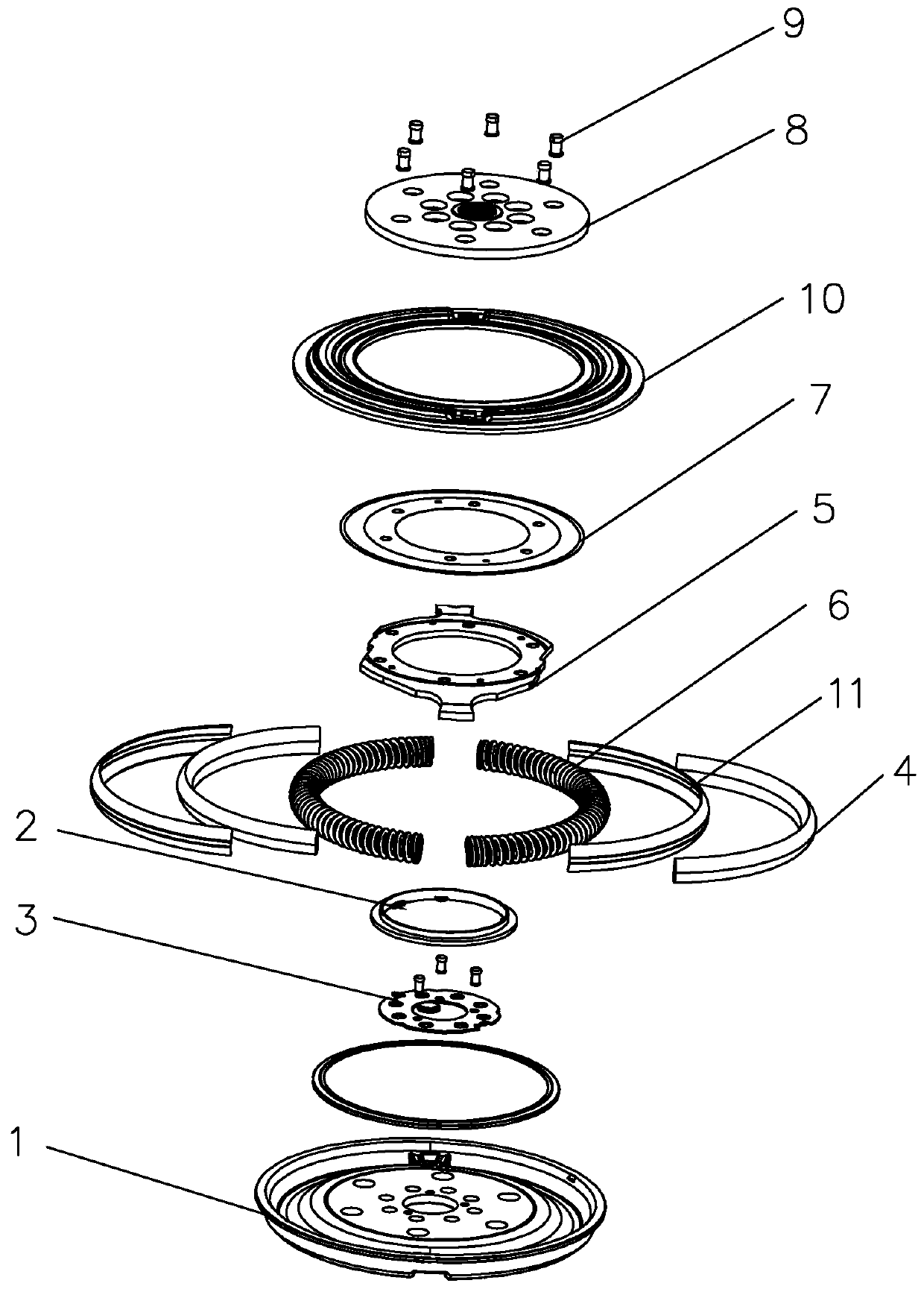

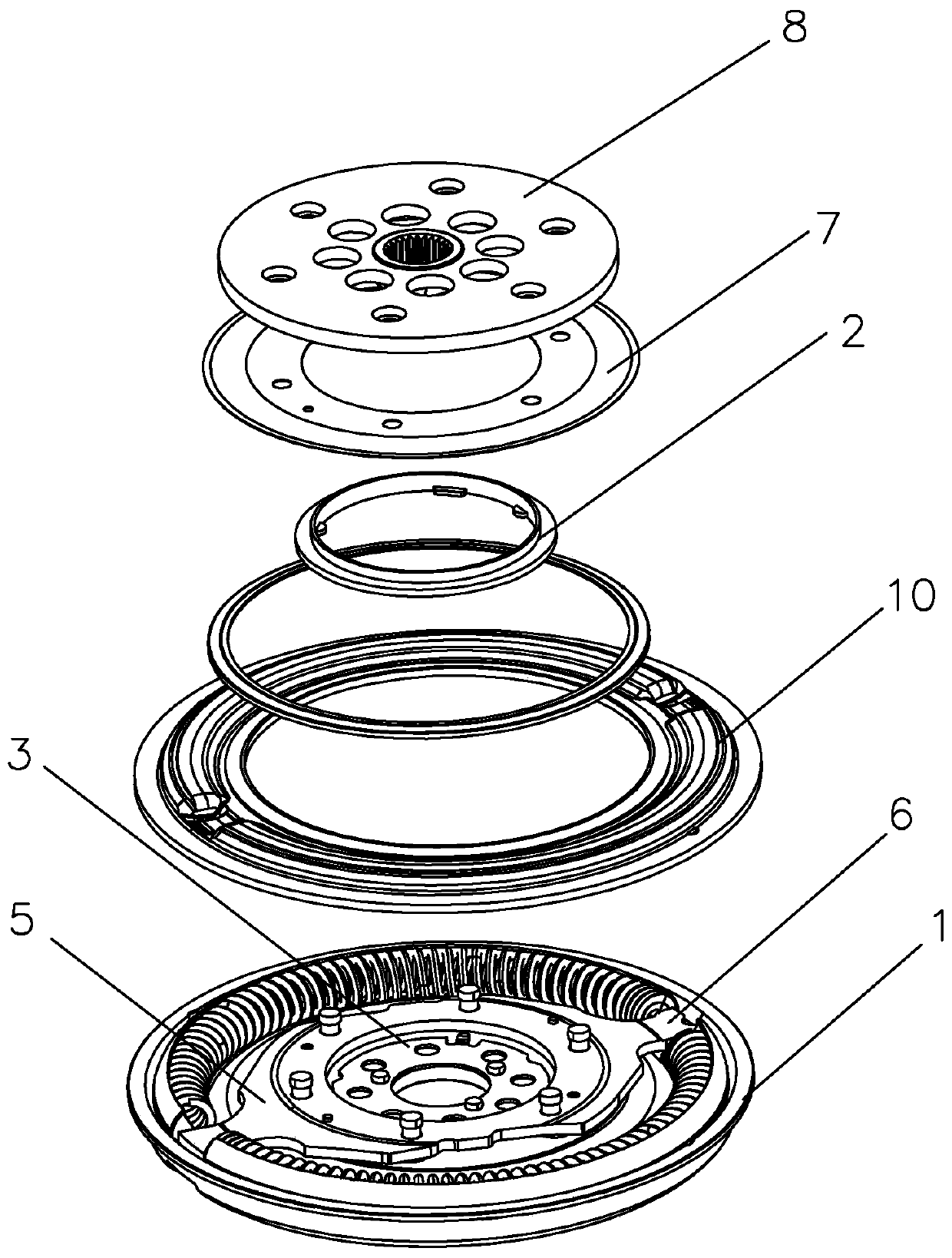

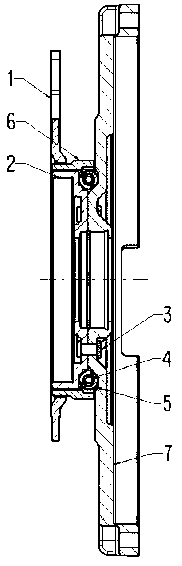

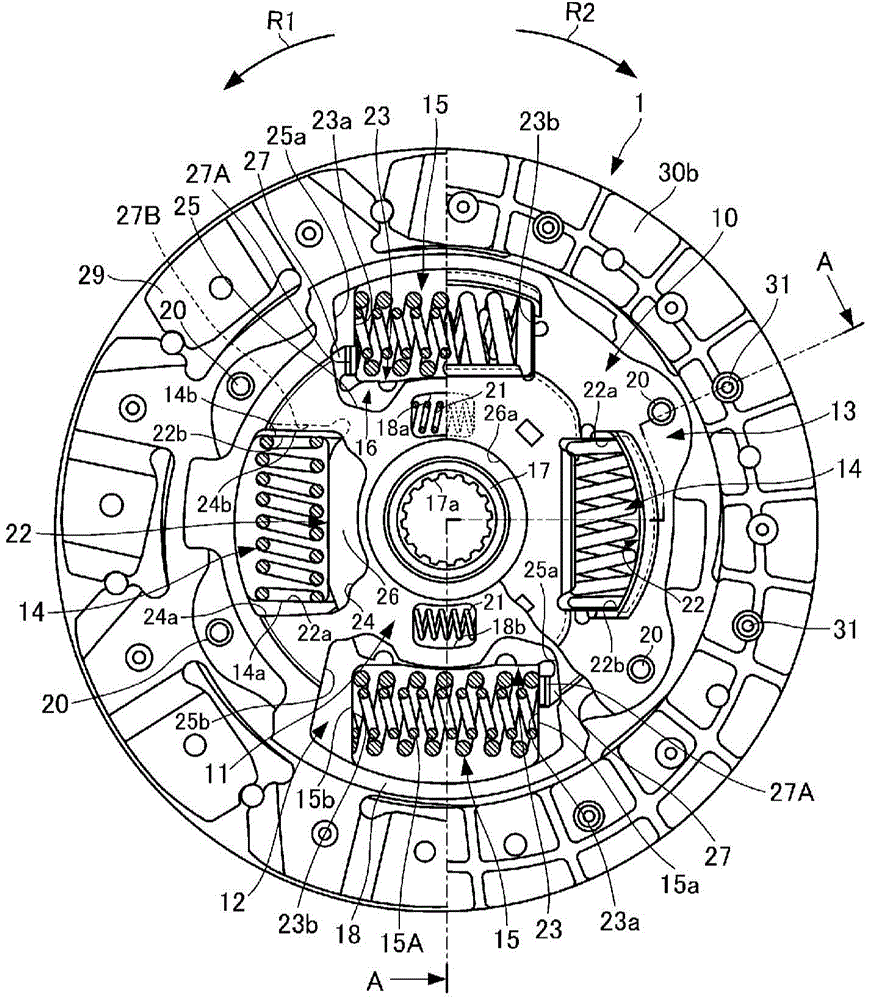

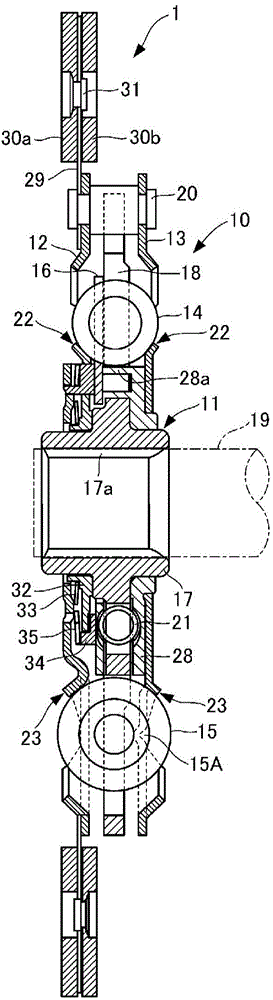

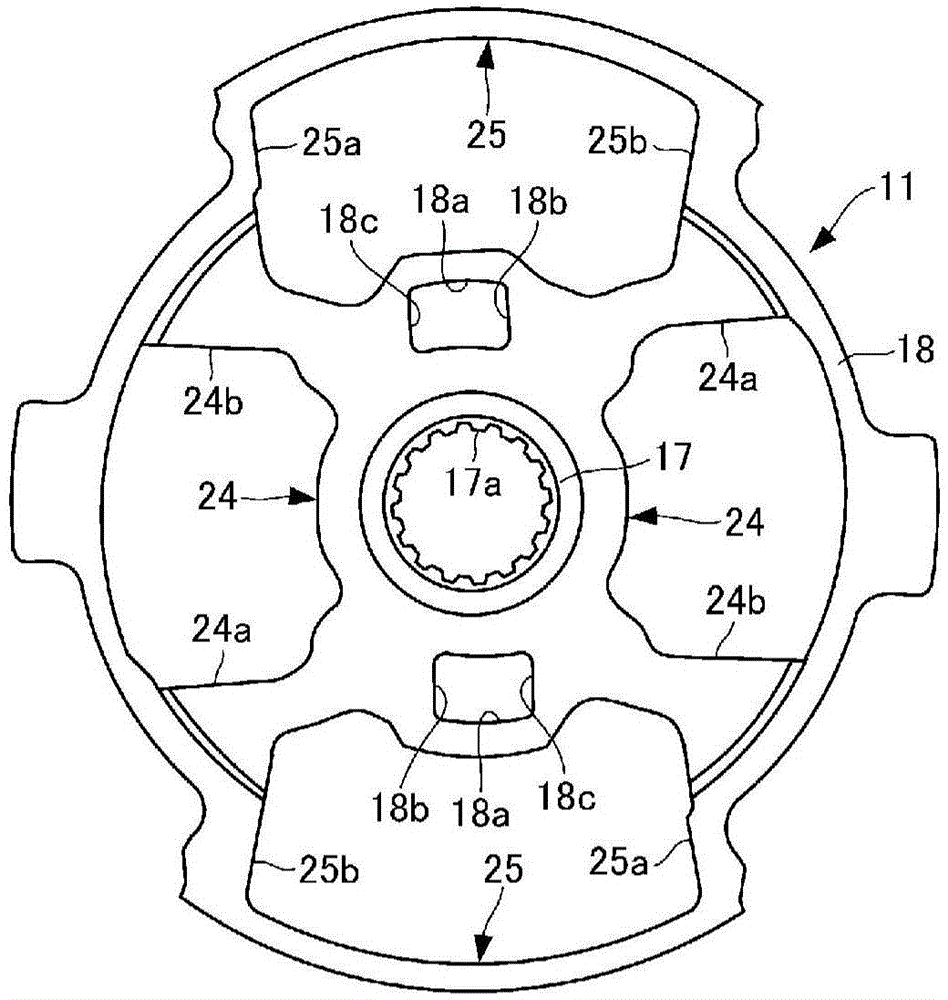

Torsion shock absorption device, flywheel and car transmission system

The invention discloses a torsion shock absorption device, a flywheel and a car transmission system, and belongs to the technical field of shock absorption. The torsion shock absorption device comprises a first shock absorber and a second shock absorber. The first shock absorber comprises a first shock absorption disc, a first elastic part and a first shock absorption disc hub, and the first shockabsorption disc is connected with the first shock absorption disc hub through the first elastic part. The second shock absorber comprises a second shock absorption disc, a second elastic part and a second shock absorption disc hub, the second shock absorption disc is connected with the second shock absorption disc hub through the second elastic part, and the second shock absorption disc is fixedly connected with the first shock absorption disc hub. The flywheel comprises the torsion shock absorption device. The car transmission system comprises the flywheel. The torsion shock absorption device has the characteristics of being large in torsion angle and good in shock absorption effect. The flywheel can effectively reduce vibration generated by transmission between an engine output shaft and a transmission input shaft. The car transmission system can effectively avoid abnormal vibration of a car body and improve the smoothness and comfort during acceleration of a car.

Owner:HAIMA AUTOMOBILE CO LTD

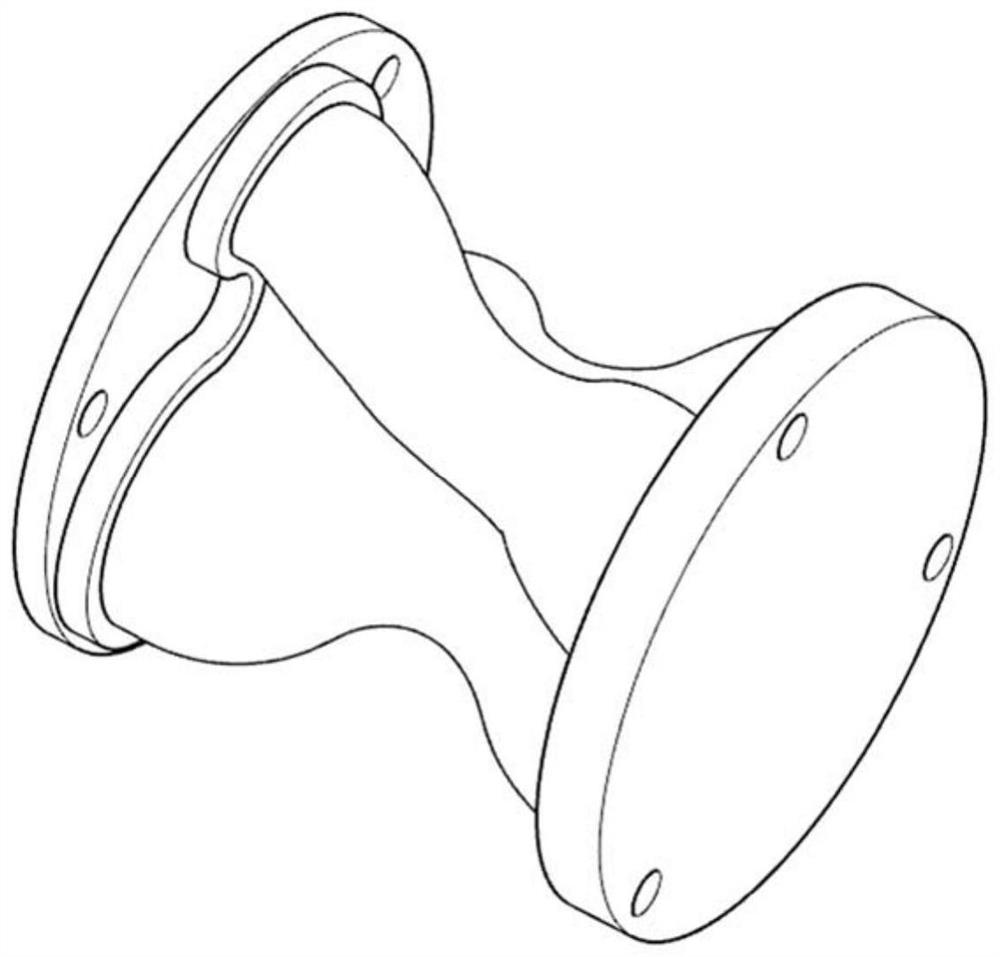

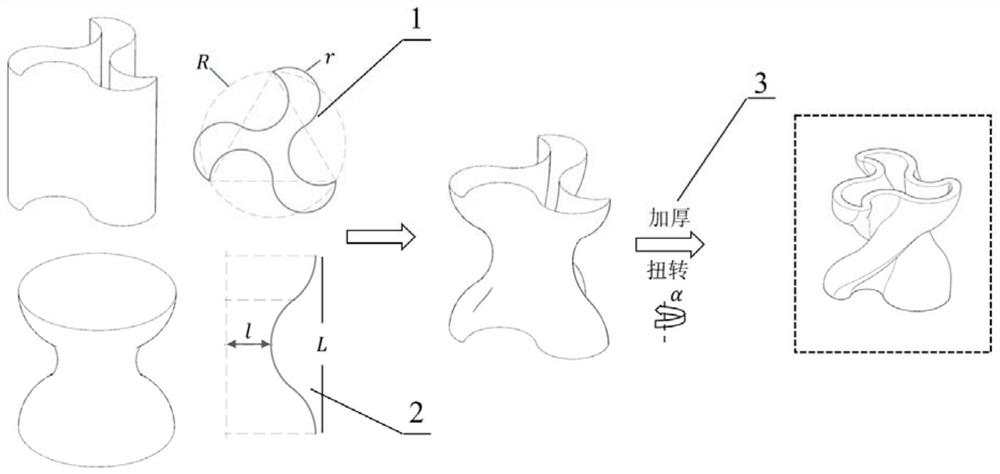

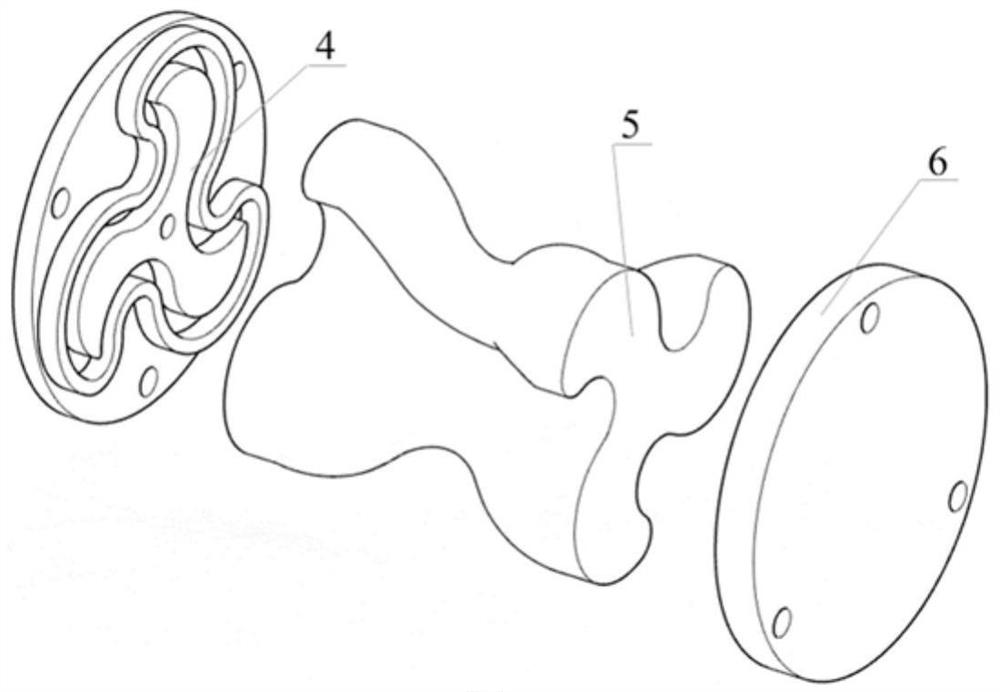

Pneumatic soft-bodied torsion actuator based on cavity body structure design

ActiveCN112894785ALarge strainStrong environmental adaptabilityProgramme-controlled manipulatorPhysicsSoft body

The invention provides a pneumatic soft-bodied torsion actuator based on a cavity body structure design. The pneumatic soft-bodied torsion actuator based on the cavity body structure design comprises a cavity body, a top flange, a bottom end cover and a connecting rod, a top mounting groove matched with the top contour surface of the cavity body is formed in the top flange, a bottom mounting groove matched with the bottom contour surface of the cavity body is formed in the bottom end cover, the top and the bottom of the cavity body are in fit connection with the top flange and the bottom end cover respectively, the connecting rod penetrates through the interior of the cavity body, and the two ends of the connecting rod are connected with the bottom end cover and the top flange respectively. According to the pneumatic soft body torsion driver based on the cavity body structure design, based on the design of a geometrical shape of an air cavity, the end cover, an air pipe, the flange and other parts are combined into a whole, and therefore the performance of an existing soft-bodied torsion actuator is improved; and the pneumatic soft-bodied torsion actuator has the characteristics of large torsion angle per unit length and strong load capacity.

Owner:SHANGHAI JIAO TONG UNIV

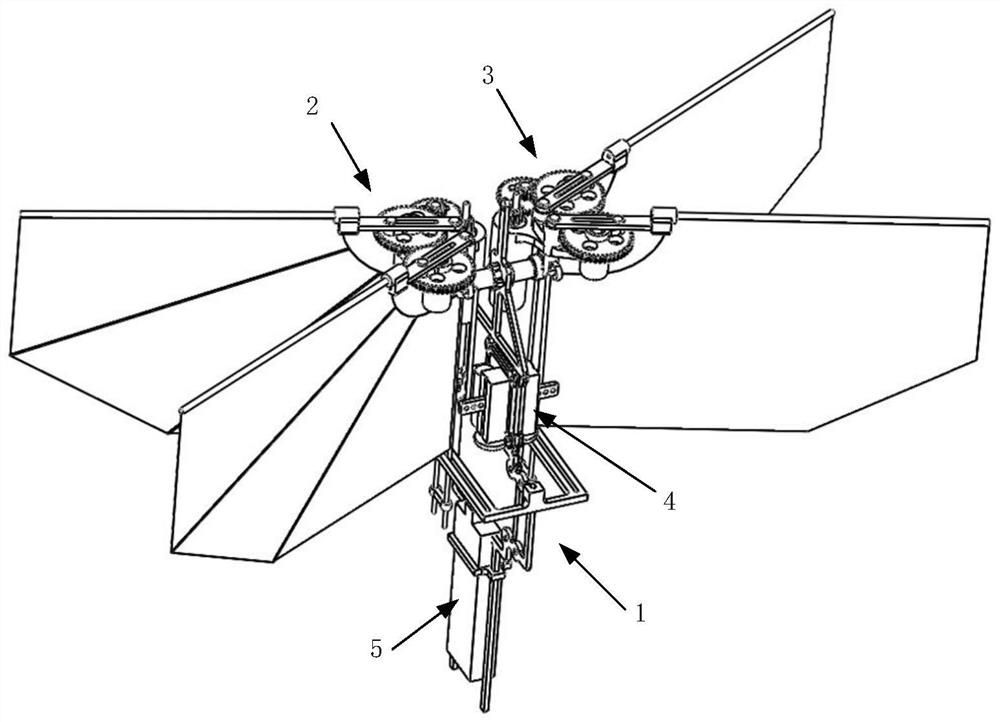

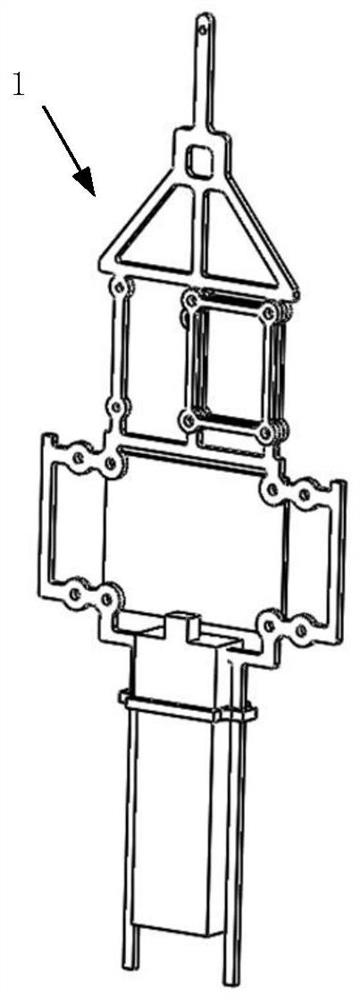

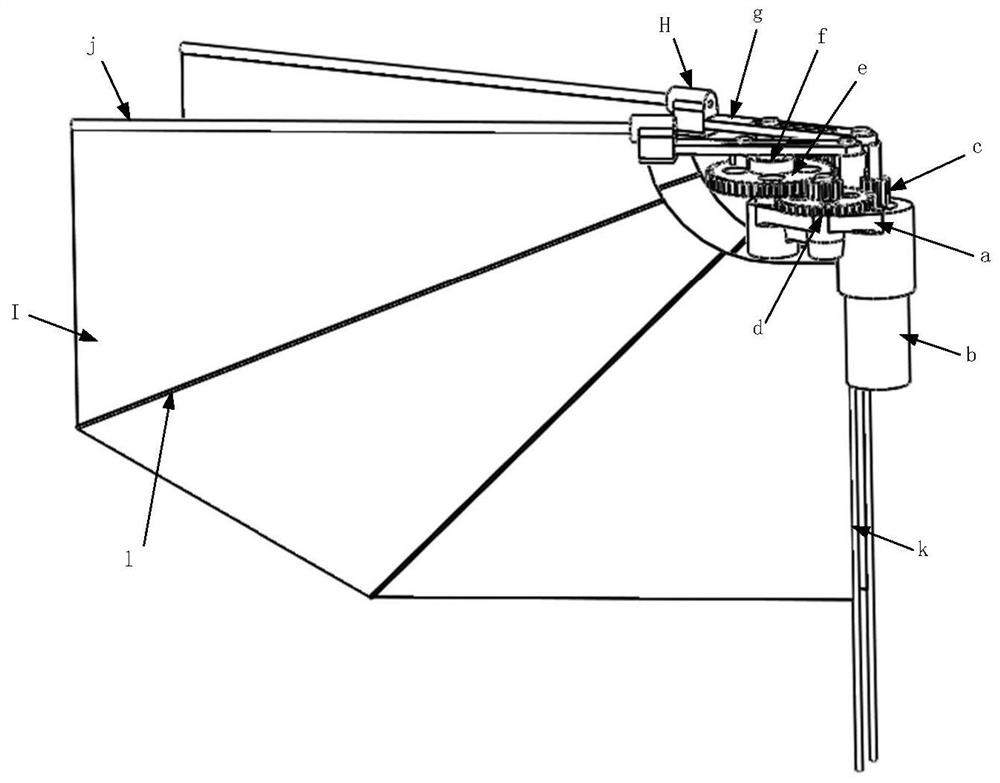

Hovering type miniature bionic double-flapping-wing flying robot

The invention discloses a hovering type miniature bionic double-flapping-wing flying robot which is composed of flapping mechanisms, a control mechanism and a power supply and control system, wherein the flapping mechanisms and the control mechanism are arranged on the two sides of a main machine frame. The flapping mechanism can rotate around the connecting shaft, power is output through the hollow cup motor, flapping motion of the bionic wings is achieved, then aerodynamic force and aerodynamic torque (rolling torque) are generated, when the bionic wings move, high lift force is generated through a clap-fling mechanism similar to insect flapping, and high aerodynamic efficiency is achieved. The control mechanism drives the whole flapping mechanism rack to rotate by virtue of a linear steering engine, so that the flapping plane of the bionic wing is changed, the aerodynamic force / moment direction is changed, and pitching and yawing torques are generated; The power supply and control system is realized by a control circuit board, and the whole system is powered by a battery. The parts are made of carbon fiber plates or 3D printing materials, so that the robot is light and small, the flight efficiency is improved, and the robot has ultrahigh maneuverability.

Owner:BEIHANG UNIV

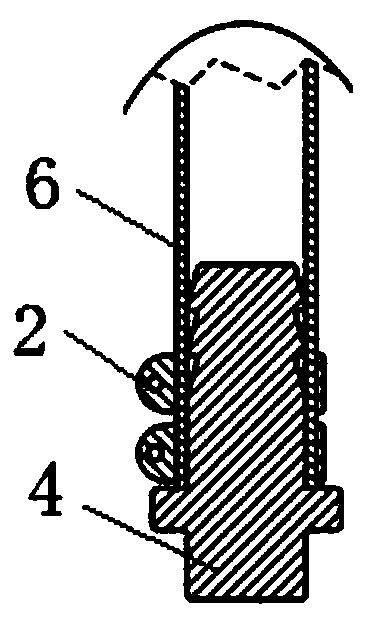

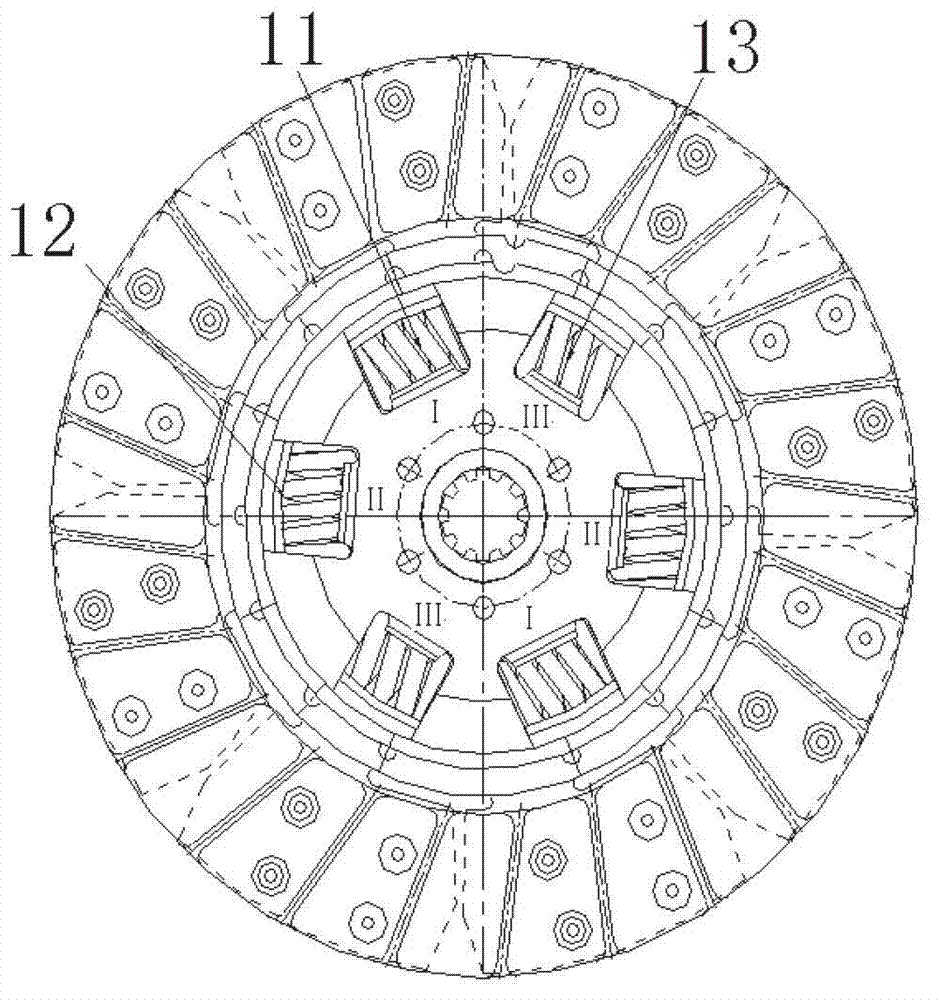

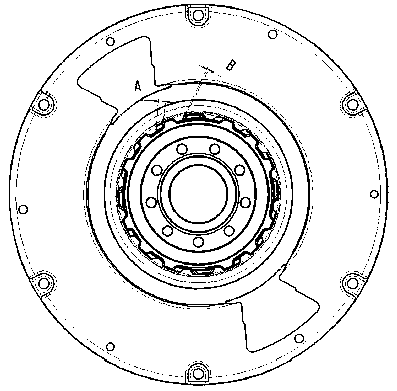

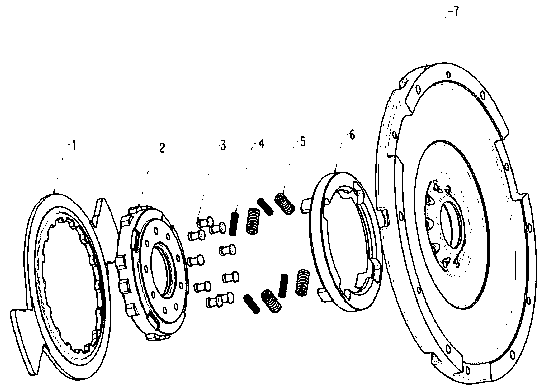

Large-torque driven disc assembly of clutch

InactiveCN102927149AReduced stiffness requirementsVibration reduction is not affectedFriction clutchesEngineeringDISC assembly

The invention discloses a large-torque driven disc assembly of a clutch. The assembly comprises a driven disc, a damping disc, a disc hub disc, a disc hub core, a waveform piece and friction pieces. The driven disc, the damping disc and the disc hub core are connected, the disc hub disc is connected with the waveform piece, the friction pieces are arranged on two sides of the waveform piece, three groups of windows are arranged on the disc hub disc, and three groups of damping springs with different rigidities are arranged in the three groups of windows. The damping spring with smallest rigidity in the disc hub disc is utilized to control the largest torsion angle, the damping spring with smallest rigidity is small in steel wire diameter and large in compression space, so that the driven disc assembly is large in torsion angle, correspondingly increases torque, omits a limit pin and notch limit, is small in disc hub rigidity requirement, and cannot affect damping effect.

Owner:WUHU DAJIE CLUTCH

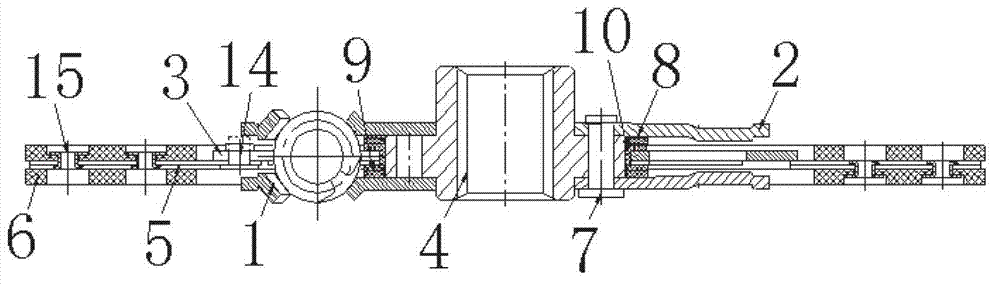

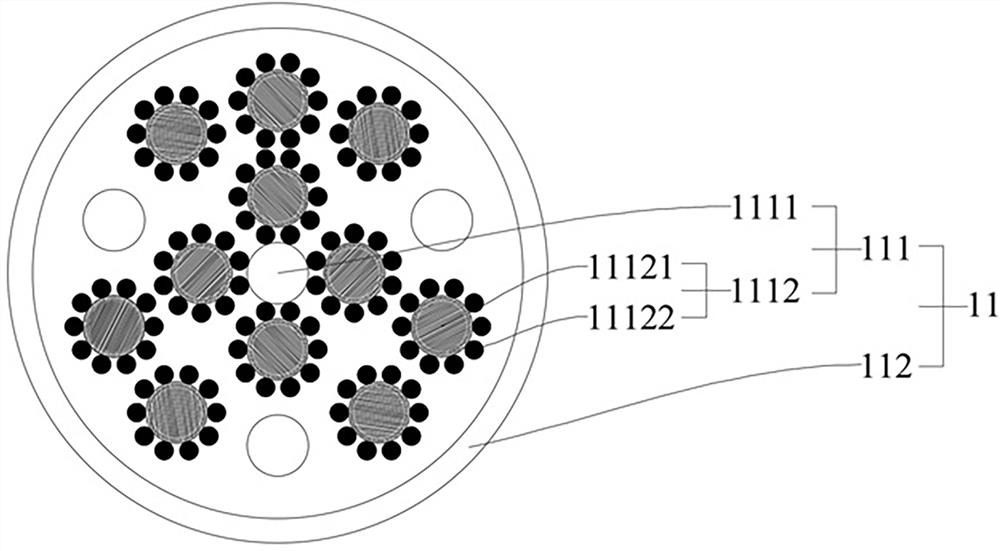

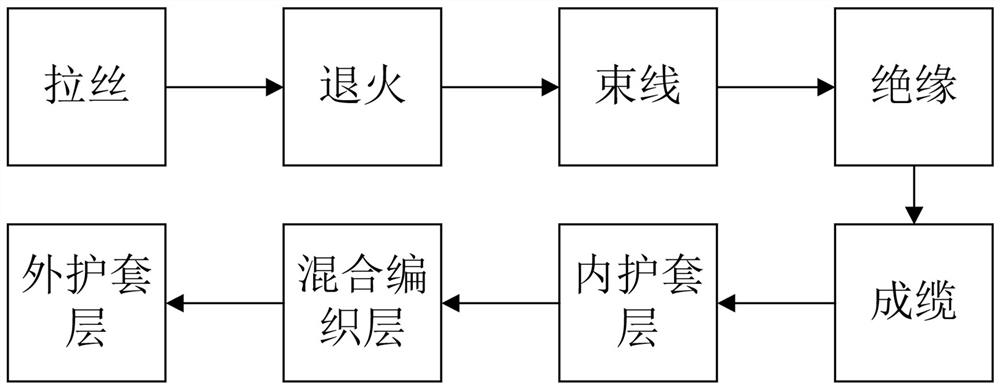

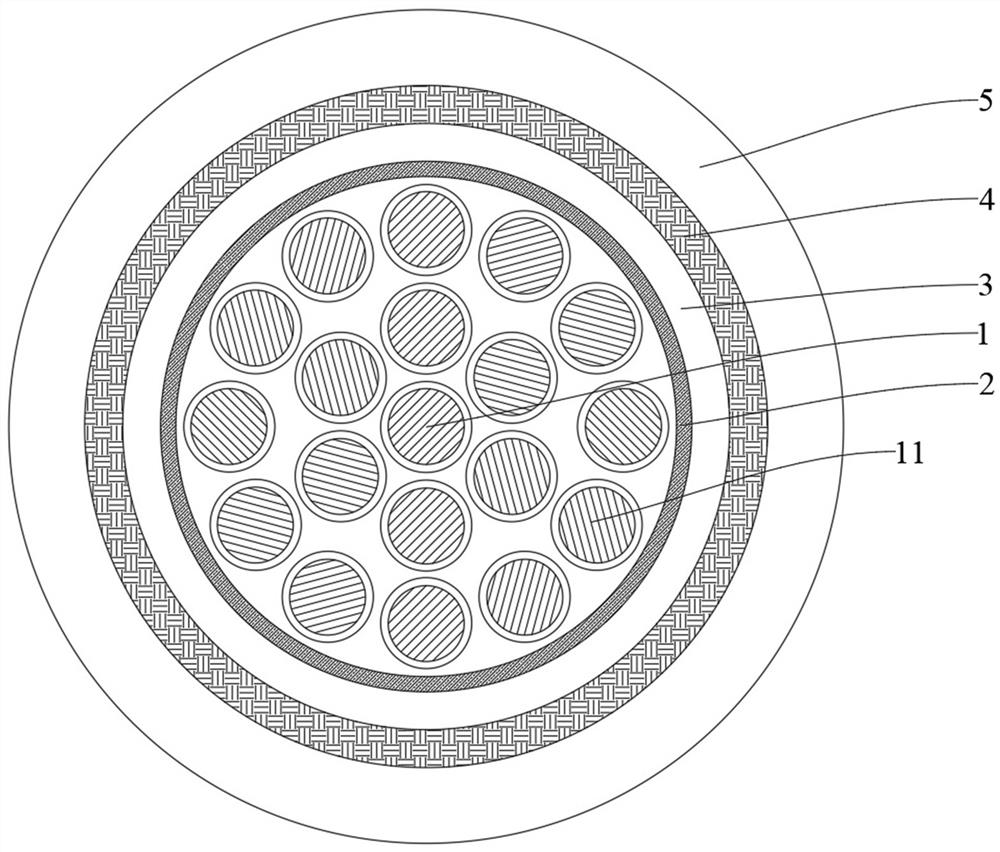

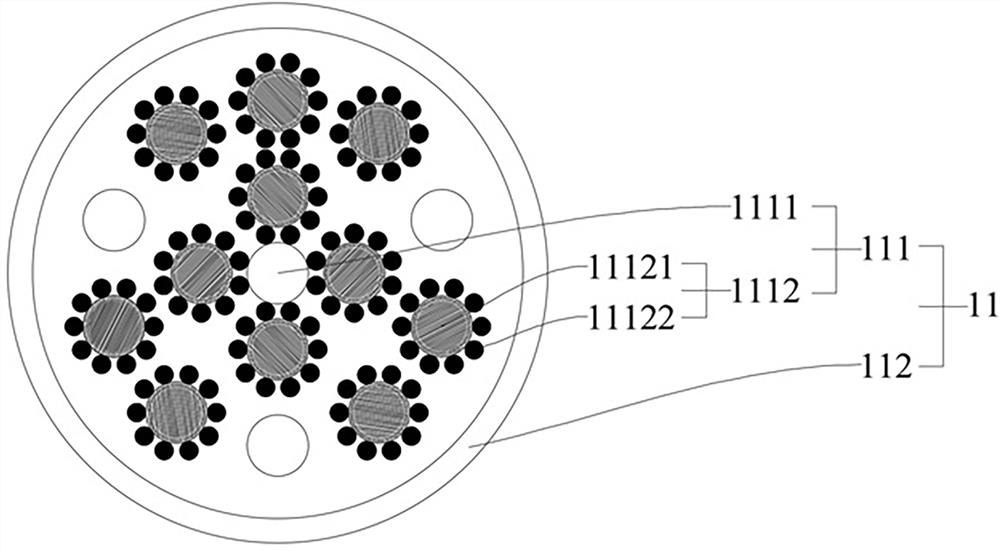

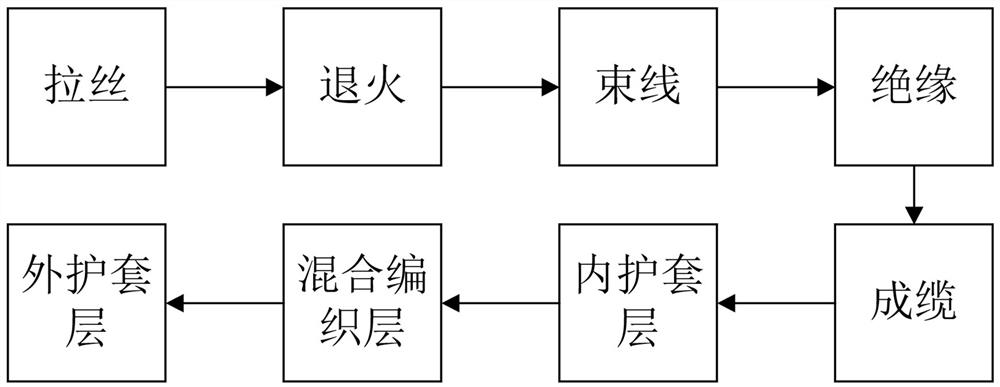

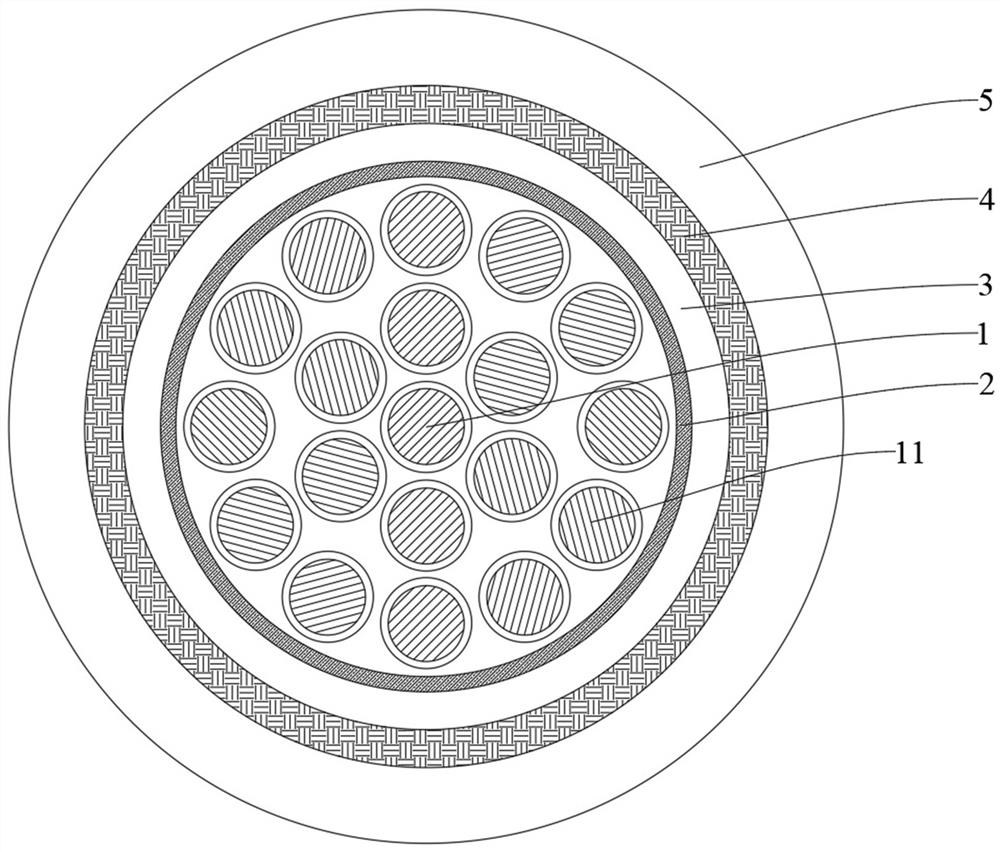

Long-life-cycle anti-torsion cable for offshore wind power

ActiveCN112908539AHigh tensile strengthIncreased torsional strengthPlastic/resin/waxes insulatorsLiquid organic insulatorsFiberElectrical conductor

The invention relates to the field of power cables, in particular to a long-life-cycle anti-torsion cable for offshore wind power, which comprises a cable core formed by a plurality of insulating wire cores and a wrapping tape layer wrapping the surface of the cable core, the outer surface of the wrapping tape layer is coated with an inner sheath layer; the outer surface of the inner sheath layer is coated with a mixed braid layer; and the outer surface of the mixed braid layer is coated with an outer sheath layer. Each insulating wire core comprises a conductor and an insulating layer wrapping the conductor. The conductor is formed by mixing and winding a plurality of copper wires and a plurality of fiber copper composite wires; each fiber copper composite wire comprises an organic fiber in the center and one or more layers of copper foils spirally wound on the outer surface of the organic fiber; the fiber copper composite wires can achieve the purposes of high-strength tensile strength, torsion resistance and light weight; and the cable is applied to a control system of an offshore high-power generator set or a control system of a land wind turbine generator set.

Owner:TBEA DEYANG CABLE CO LTD

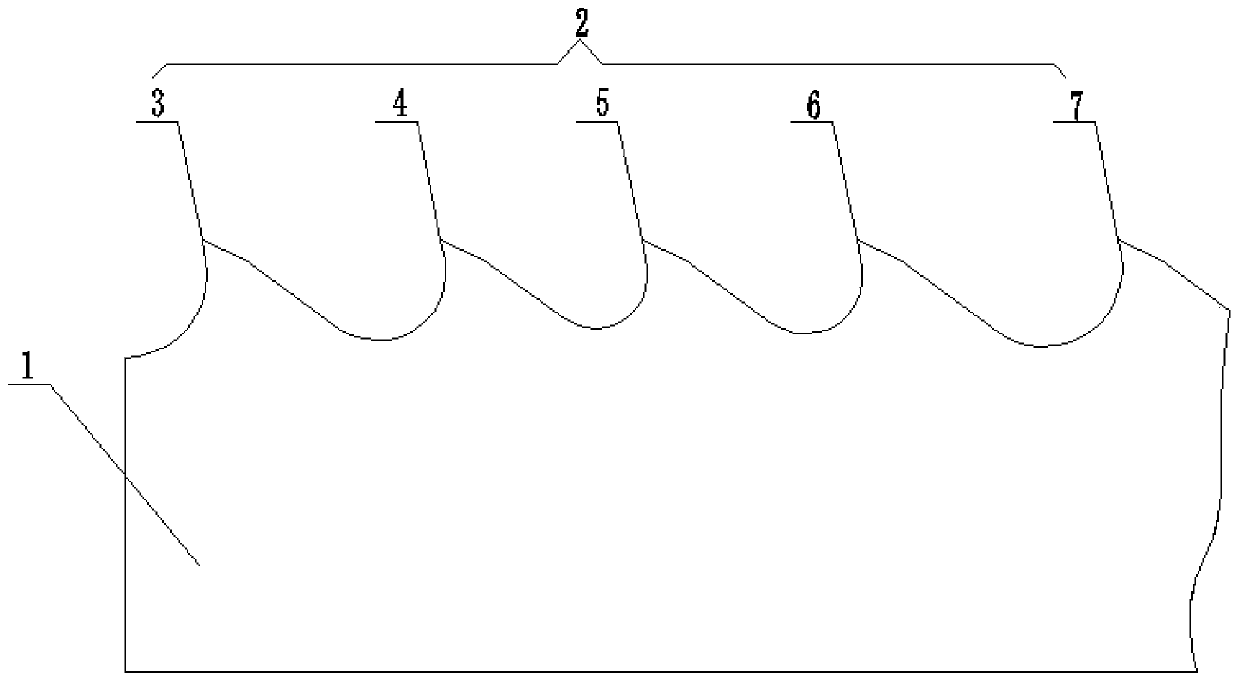

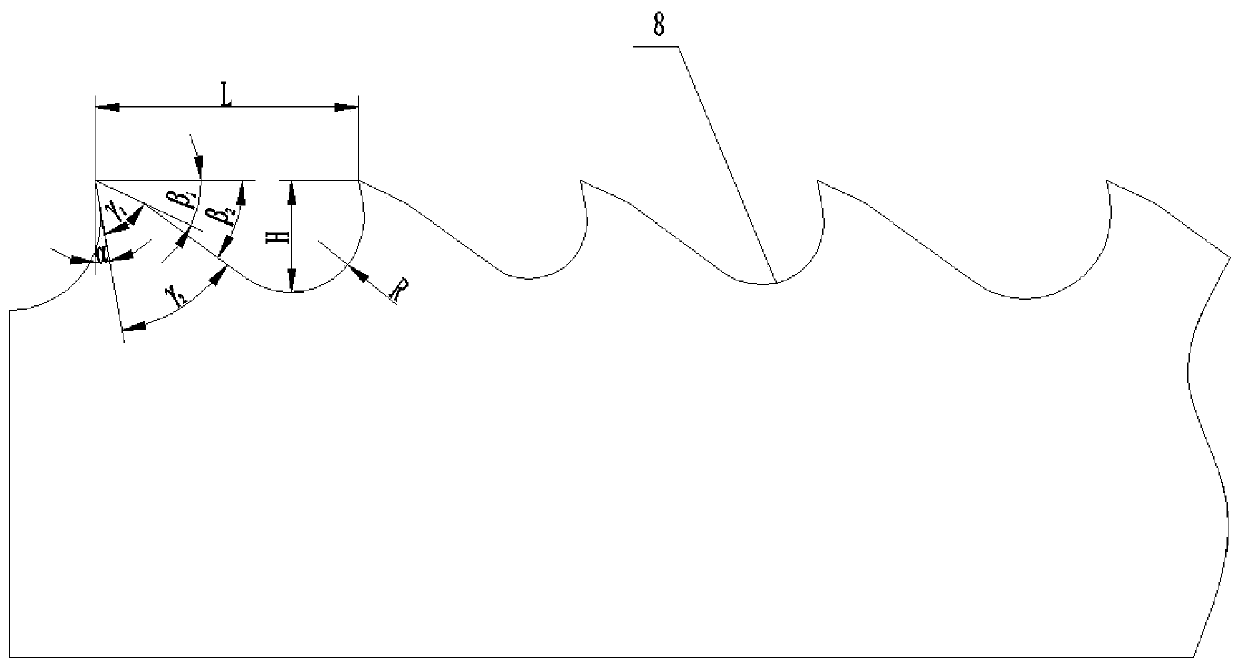

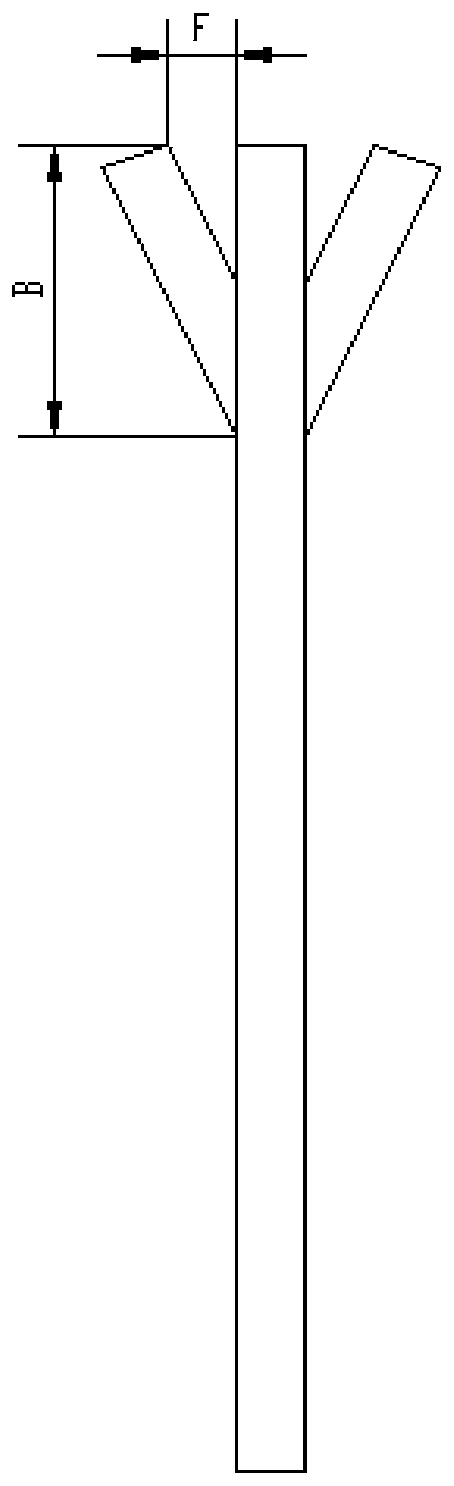

A Bimetallic Band Saw Blade with 2/3t Variational Tooth Quantity and Twisted Tooth Profile

Owner:LIAONING INST OF SCI & TECH +1

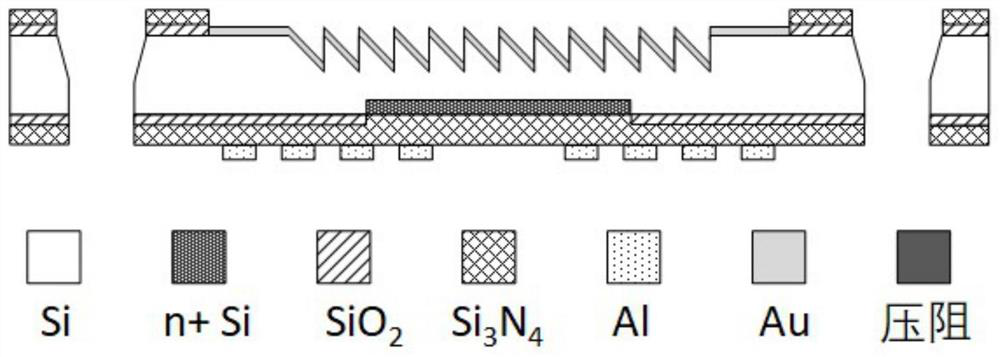

Micro reflector array manufacturing method

ActiveCN101718906BIncrease the effective areaReduce the effective areaOptical elementsEtchingLow voltage

The invention discloses a micro reflector array manufacturing method which is used for manufacturing micro reflector array with high fill factors, big-angle torsion and big array. The method adopts bulk-silicon MEMS processing technology, a vertical comb driving mode, wafer bonding technology and etching technology and is characterized in that the wafer is bonded after a middle driver layer is processed, a layer of reflector surface is covered above the driver layer; on the basis, a deep etching release technology is adopted to release a shore reserved in the driver layer to realize micro reflector torsion, thus realizing the purpose of driving with high fill factors, big-angle torsion and low voltage.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

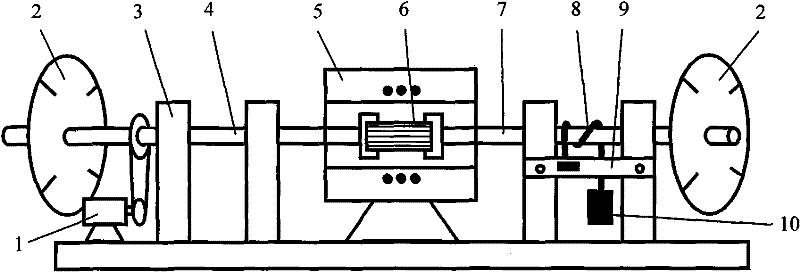

Rotating and twisting device of optical fiber image inverter

ActiveCN101819295BAvoid uniformityIncrease the twist angleBundled fibre light guideEngineeringDistortion

The present invention discloses a rotating and twisting device of an optical fiber image inverter which is a device with braking function, simplicity and practical utility, thus realizing rotational heating and twisting of the optical fiber composite silk rod from beginning to end, overcoming the defects of uneven heating, easy cracking and severe distortion due to falling deviation of a workpiece in an ordinary twisting method of an optical fiber image inverter, and dramatically enhancing the qualified rate of the product quality. The device has the advantages of simplicity, practical utility, low cost of manufacture and easy operation.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

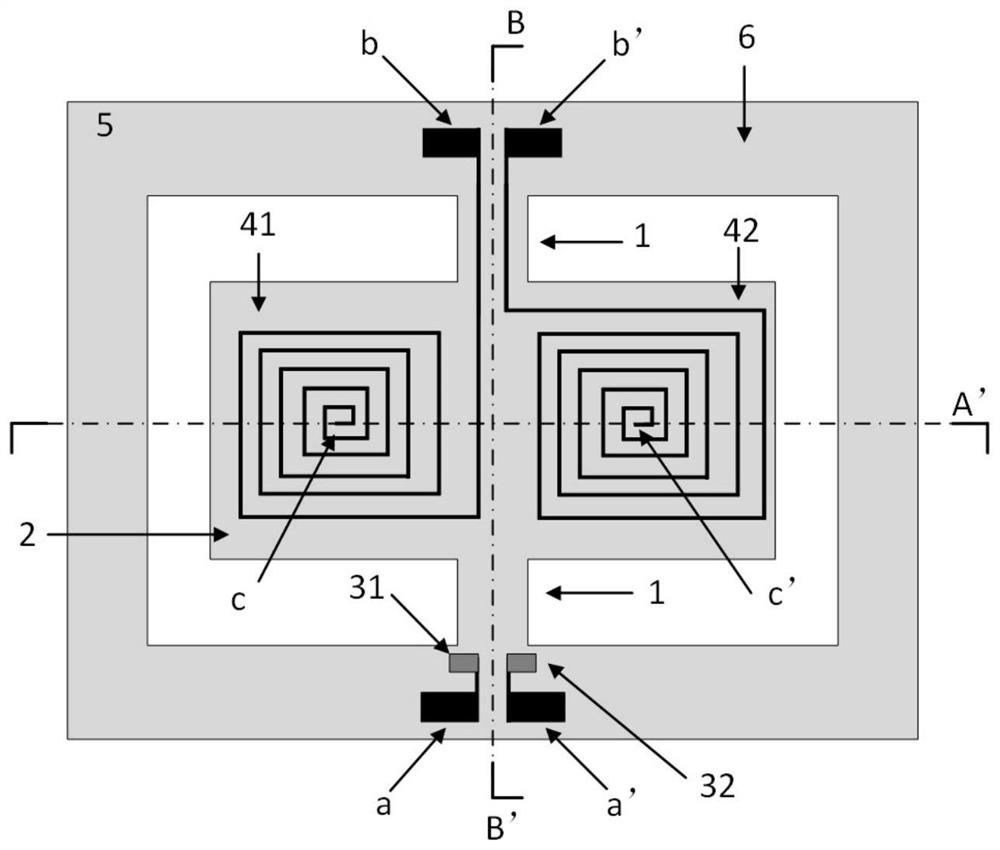

Push-pull scanning grating

The invention provides a push-pull scanning grating, which is characterized by comprising a supporting frame, a reflection grating, a torsion beam, an electromagnetic push-pull driver used for drivingthe reflection grating to be twisted and an angle sensor used for detecting the twisting angle of the grating, wherein the reflecting grating is connected with the supporting frame through two torsion beams which are distributed on the two side edges and are symmetrically arranged; the axes of the two torsion beams coincide with the center line of the side edge of the reflection grating; the angle sensor is arranged at the joint of one of the torsion beams and the supporting frame; the electromagnetic push-pull driver comprises a driving coil and two driving electrodes; and driving signals are input through the driving electrodes, driving coils arranged on the two side edges of the center line of the reflection grating are controlled to form currents with opposite flow directions, and thereflection grating is driven to twist. According to the invention, the structure is simple, the power consumption can be effectively reduced, and the stability of the scanning grating is enhanced.

Owner:CISDI RES & DEV CO LTD

Triaxial accelerometer

InactiveCN114609413AGuaranteed poor qualityEnsure that the Z-axis masses on both sides of the cavity have poor qualityAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsTriaxial accelerometerEngineering

The embodiment of the invention relates to the technical field of accelerometers, in particular to a three-axis accelerometer which comprises a substrate and two first anchor points symmetrically arranged on the substrate, the substrate is further provided with a Z-axis detection structure, the Z-axis detection structure comprises a Z-axis mass block, the Z-axis mass block is provided with a cavity, and the Z-axis mass block is provided with a second anchor point. The two first anchor points are symmetrically arranged on the two opposite sides of the cavity in the first direction. The torsion beam is located in the cavity, the first anchor point is connected with the side wall of the Z-axis mass block in the first direction through the torsion beam, the torsion beam coincides with the center line of the cavity, and the torsion beam deviates from the center line of the Z-axis mass block in the first direction; the X-axis detection structure and the Y-axis detection structure are located in the cavity. According to the embodiment of the invention, the detection precision of the triaxial accelerometer can be improved.

Owner:绍兴圆方半导体有限公司

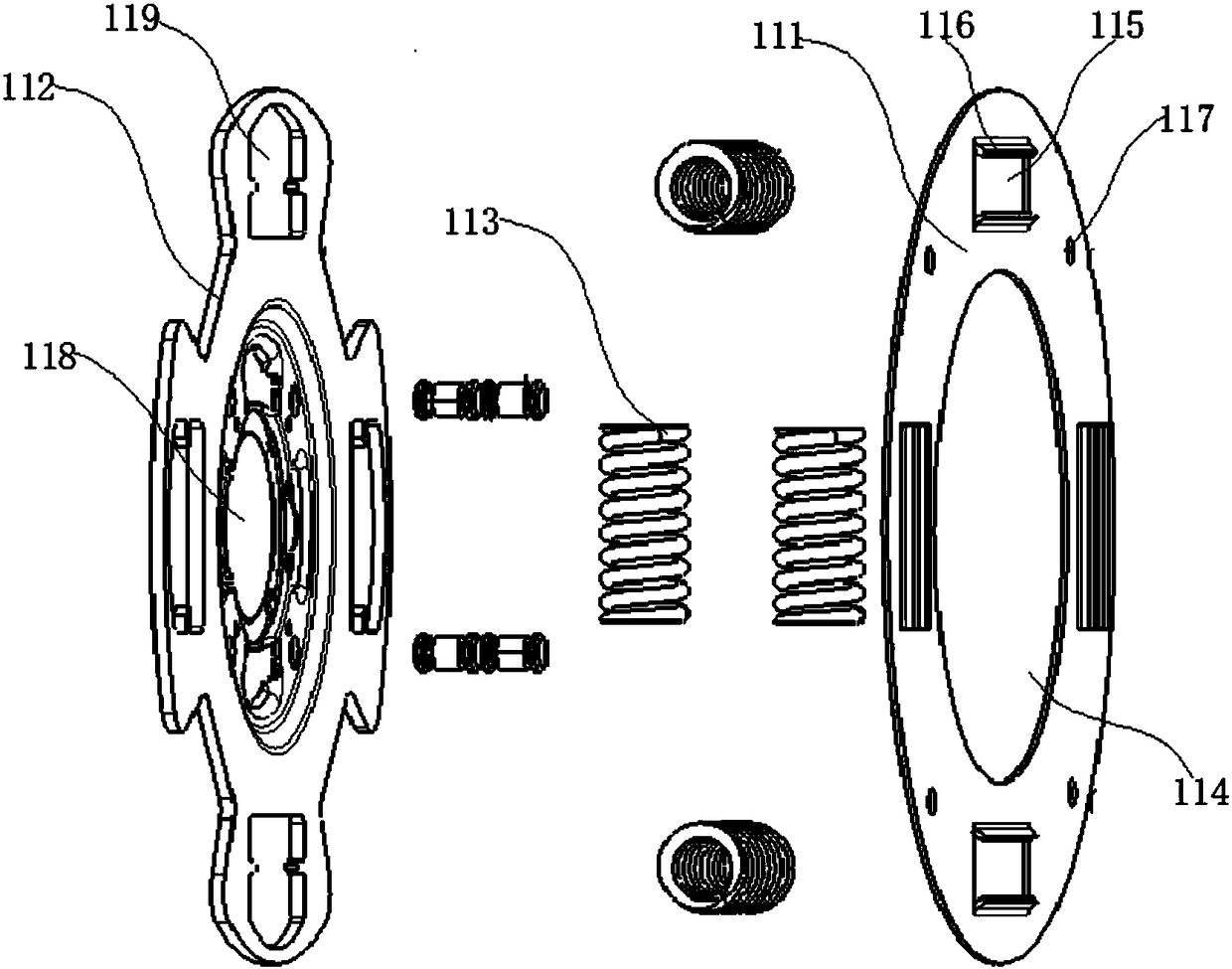

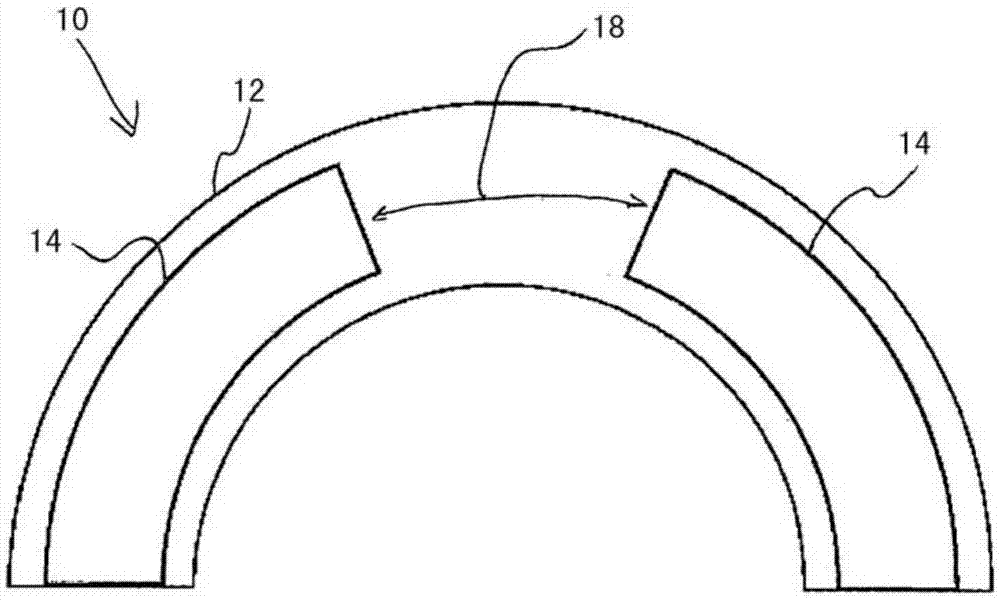

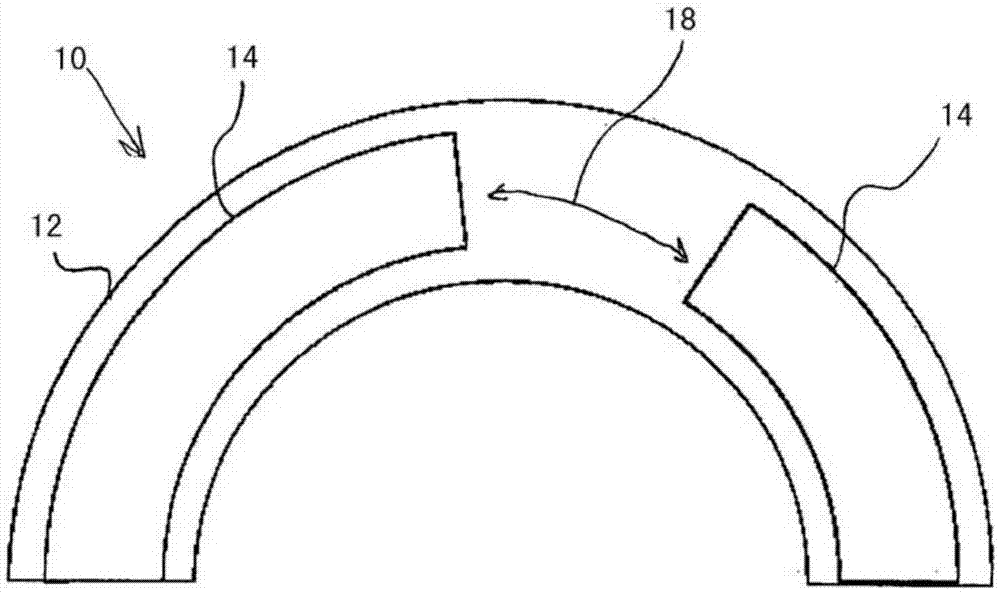

Bow spring system for dual mass flywheels and dual mass flywheels

InactiveCN103765038BLow costReduce the spring rateVibration suppression adjustmentsFlywheelTorsional vibration

The invention relates to a bow spring system for a dual-mass flywheel for damping torsional vibration, provided with a starting bow spring (22) for damping torsional vibration, a first additional bow spring (24) for damping torsional vibration arranged parallel to the starting bow spring and a second additional bow spring (26) for damping torsional vibration arranged parallel to the starting bow spring (22), wherein the second additional bow spring (26) is connected in series with the first additional bow spring, wherein the starting bow spring has a spring constant Ds that is less than the spring constant D of the first additional bow spring and less than the spring constant D2 of the second additional bow spring, wherein upon compression of the bow spring system over a total spring path Sges the second additional bow spring blocks before the first additional bow spring and before the starting bow spring.

Owner:SCHAEFFLER TECH AG & CO KG

Stiffness adjustable large flexible torsion spring for steering gear loading

ActiveCN111173871BAdjustable stiffnessGuaranteed geometric stabilityVibration dampersTorsion springsEngineeringTorsion spring

Owner:哈尔滨工大航博科技有限公司

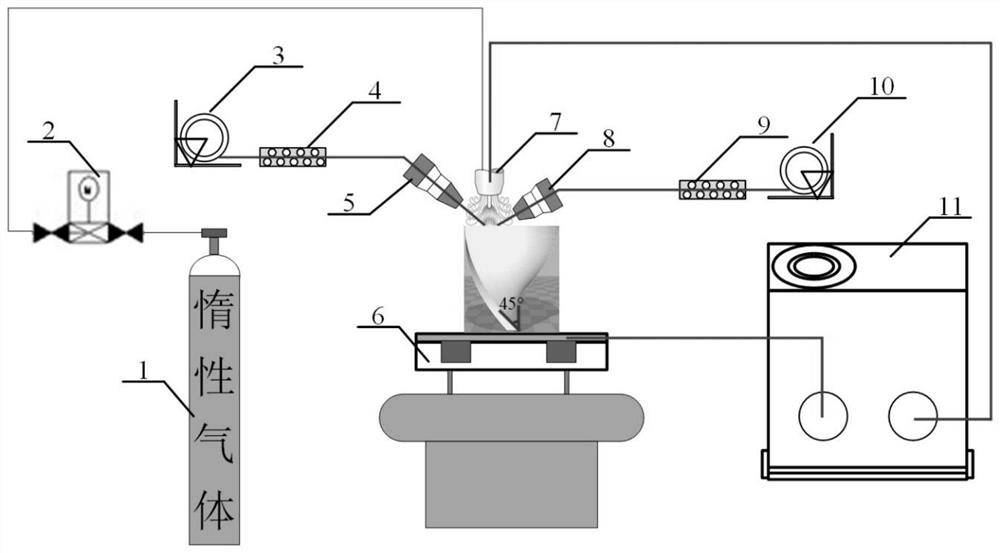

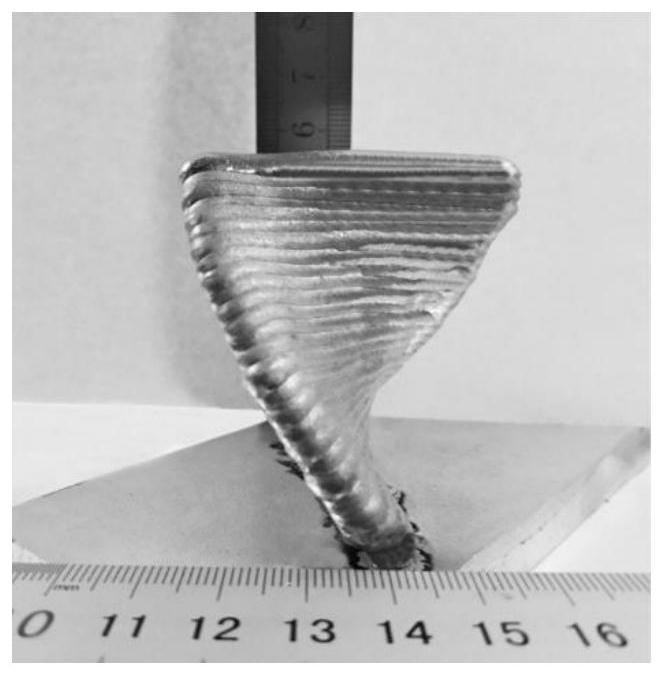

Low-energy-consumption heterogeneous multi-wire pre-melting-TIG additive manufacturing method

ActiveCN114346372ASolve the problem of poor synchronization of meltingImprove stabilityIncreasing energy efficiencyWelding accessoriesProcess engineeringEnergy consumption

The invention belongs to the technical field of additive manufacturing, and relates to a low-energy-consumption heterogeneous multi-wire pre-melting-TIG additive manufacturing method, an electric arc additive manufacturing system 3D printing system is adopted for forming manufacturing, a plurality of wire feeding units are arranged in the electric arc additive manufacturing system 3D printing system, and welding wires on the wire feeding units are made of different materials; a preheating system is arranged in a 3D printing system of the electric arc additive manufacturing system, a welding wire is preheated through the preheating system to be used for supplementing melting energy difference values needed by welding wires made of different materials under the same forming current in a differentiated mode, and then 3D printing is conducted through a TIG welding gun. According to the method, energy differentiation treatment of welding wires made of different materials is achieved by accurately controlling preheating, the arc current in the forming process is reduced, energy consumption is reduced, low-energy-consumption additive manufacturing of multiple materials under the same arc is achieved while the forming speed is increased, and heterogeneous material components with uniform components are obtained.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

multifunctional wrist

InactiveCN103432721BPlay a role in self-defensePositive pressure increases or decreasesDumb-bellsResilient force resistorsEngineeringCylindrical lens

The invention discloses a multifunctional wrist force measurer which comprises a handle I and a handle II which are connected with each other. The key technical point is that the handle I comprises a columnar body I and a cylindrical bulge; the cylindrical bulge is coaxial with the columnar body; a bolt hole is formed in the axis of the cylindrical bulge; the handle II comprises a columnar body II; a cylindrical groove I butted with the cylindrical bulge is formed in the inner end face of the columnar body II; a cylindrical groove II is formed in the outer end face of the columnar body II; a through hole is formed in the center of a columnar body connected with the cylindrical groove I and the cylindrical groove II; a spring is arranged in the cylindrical groove II; the inner end of the spring is in contact with the bottom of the groove II, and the outer end of the spring is in contact with a bearing; a bolt runs through the bearing, the spring and the through hole and then is screwed into the bolt hole in the handle I to be fixed; a detachable hand shank is also arranged at each of two ends of the multifunctional wrist force measurer. The multifunctional wrist force measurer is simple in structure, easy to mount and operate, economical, practical and convenient to carry.

Owner:潘峰

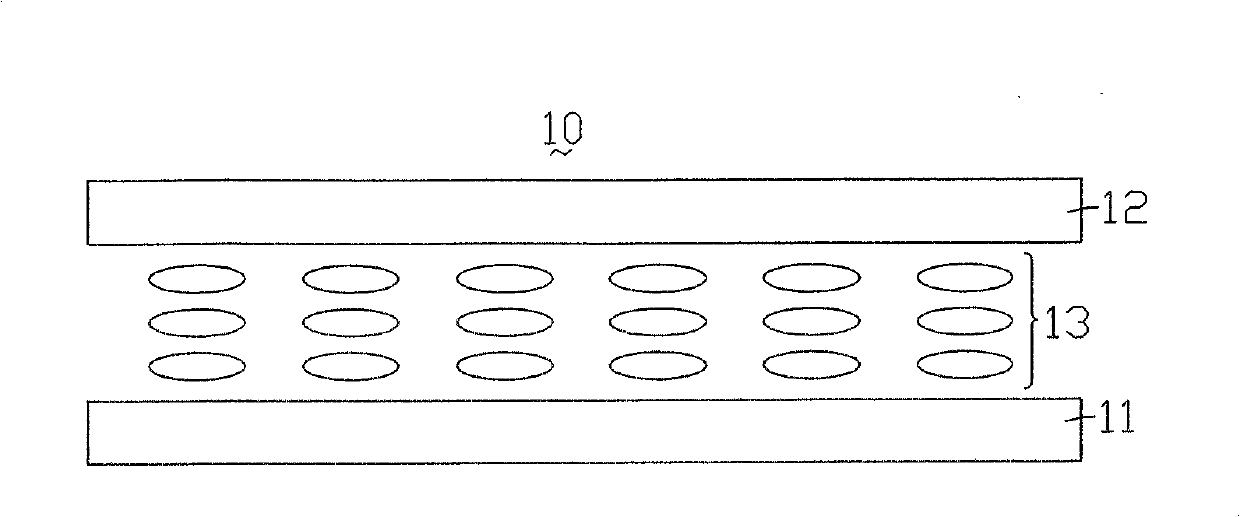

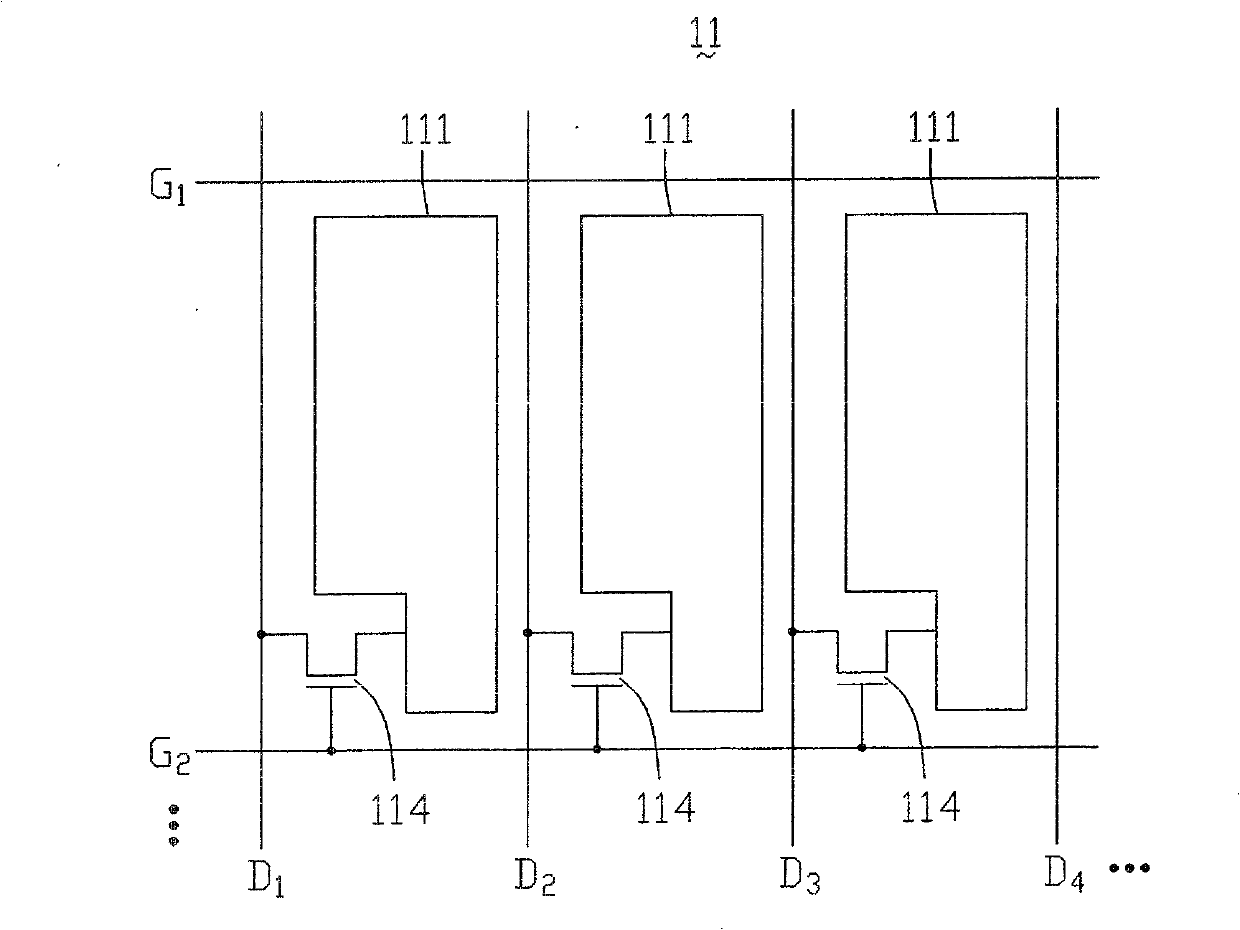

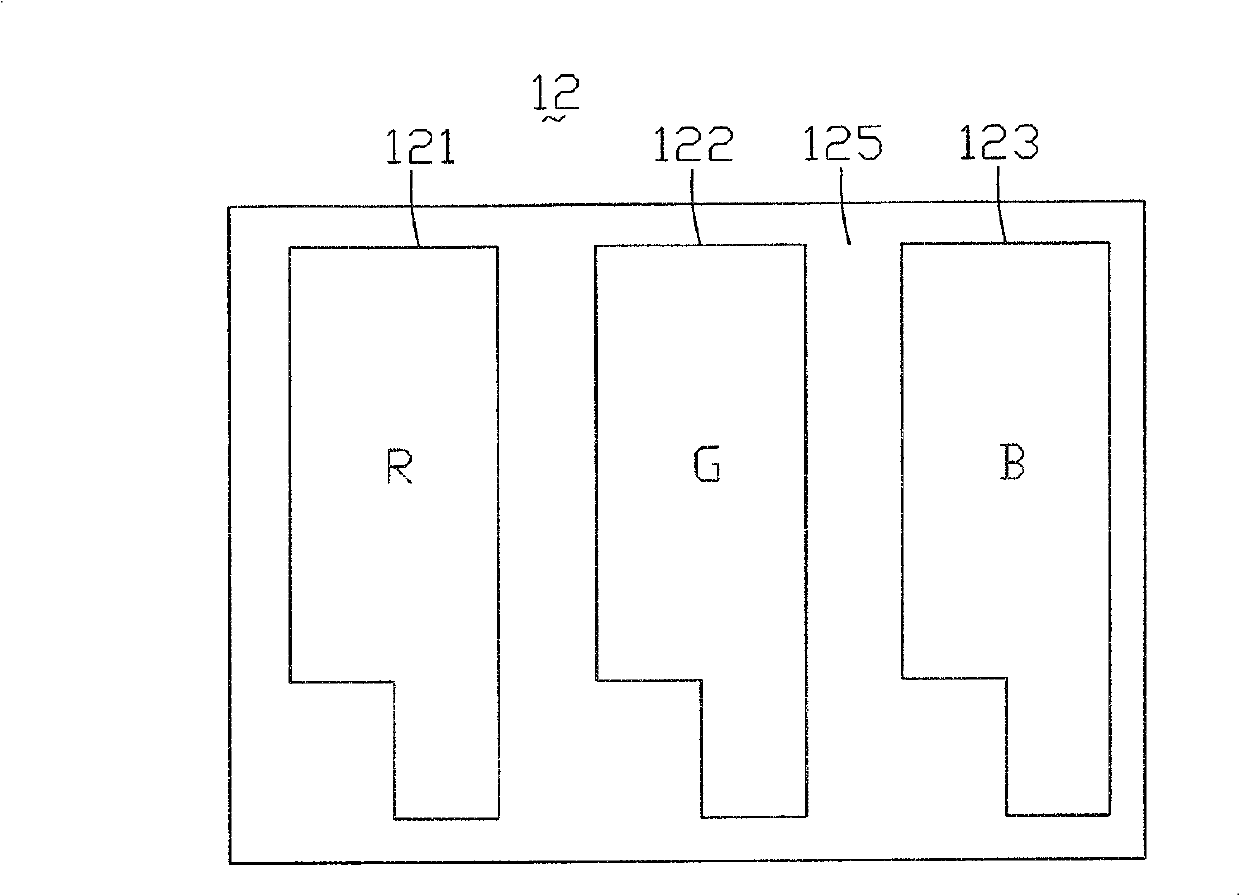

Liquid crystal display device and its driving method

InactiveCN100516998CShort response timeIncrease the twist angleStatic indicating devicesNon-linear opticsLiquid-crystal displayComputer science

The invention provides a liquid crystal display which comprises a plurality of picture elements, a plurality of scanning lines and a plurality of datawires, wherein each picture element comprises a red sub-pixel, a green sub-pixel and a blue sub-pixel. The red sub pixel comprises a first red sub-pixel and a second red sub-pixel, the same scanning line provides sweep signals for the first and the second red sub-pixels, and two datawires respectively provide data voltage for the first and the second red sub-pixel. The green sub-pixel comprises a first green sub-pixel and a second green sub-pixel, the same scanning line provides sweep signals for the first green sub-pixel and the second green sub-pixel, and two datawires respectively provide data voltage for the first green sub-pixel and the second green sub-pixel. The blue sub-pixel comprises a first blue sub-pixel and a second blue sub-pixel, the same scanning line provides sweep signals for the first blue sub-pixel and the second blue sub-pixel, and two datawires respectively provide data voltage for the first blue sub-pixel and the second blue sub-pixel.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

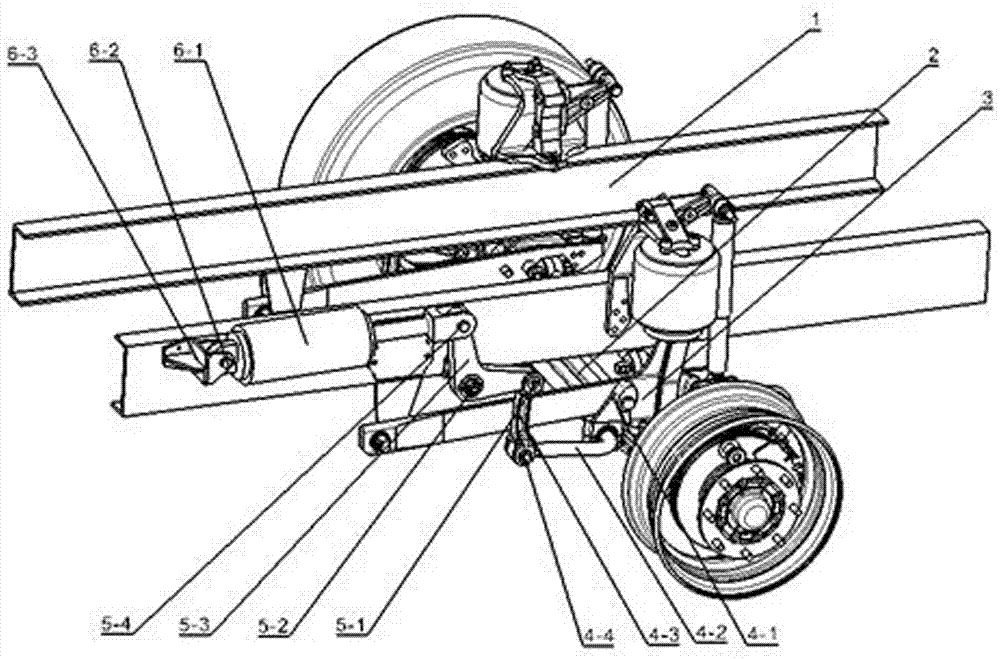

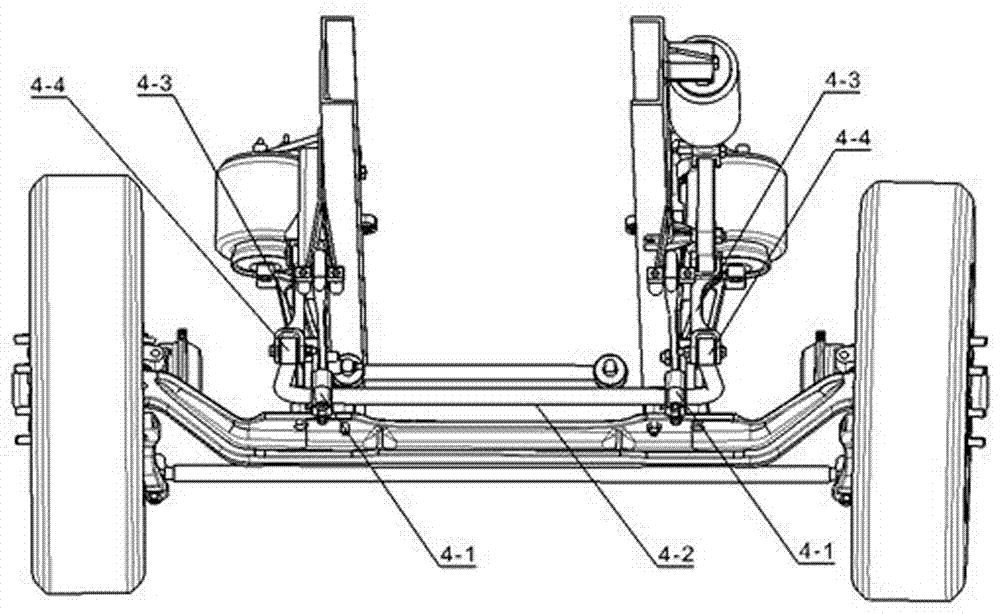

A vehicle and its active lateral stabilizing device

ActiveCN104325858BImprove ride comfort performanceLow anti-tilting momentInterconnection systemsEngineeringPower output

The invention relates to a vehicle and an active transverse stabilizing device thereof. The active transverse stabilizing device comprises a transverse stabilizing rod and a driving device, wherein the transverse stabilizing rod is used for being arranged on a corresponding suspension, and the driving device is arranged at at least one end of the transverse stabilizing rod; the driving device comprises a power output member which is used for being arranged on a corresponding vehicle body, and the driving device is provided with a power output end which is in transmission connection with a corresponding end of the transverse stabilizing rod so as to drive the transverse stabilizing rod to twist. The invention provides the active transverse stabilizing device, which can actively adjust the rolling resisting moment of the transverse stabilizing rod to the vehicle body, and the vehicle employing the active transverse stabilizing device.

Owner:ZHENGZHOU YUTONG BUS CO LTD

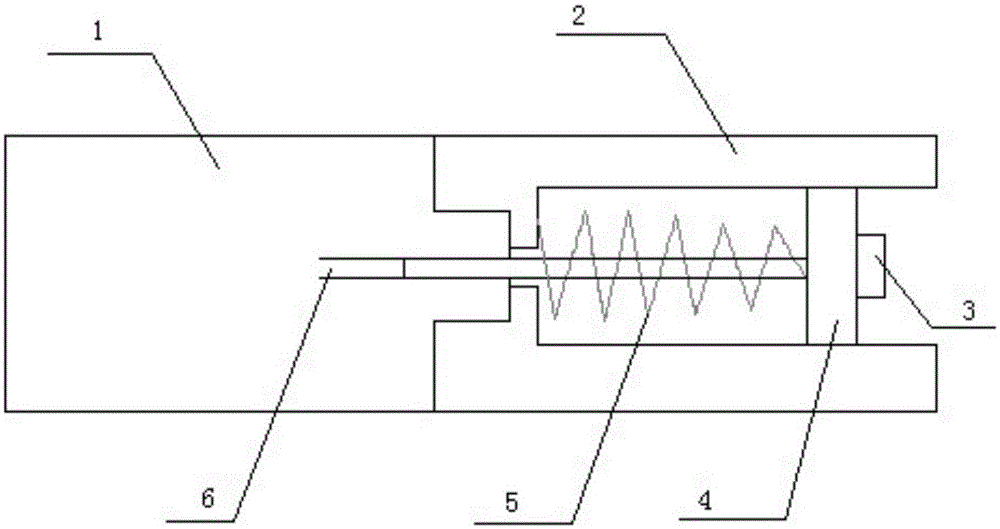

Multifunctional wrist force measurer

InactiveCN103432721APlay a role in self-defensePositive pressure increases or decreasesDumb-bellsResilient force resistorsEngineeringWrist

The invention discloses a multifunctional wrist force measurer which comprises a handle I and a handle II which are connected with each other. The key technical point is that the handle I comprises a columnar body I and a cylindrical bulge; the cylindrical bulge is coaxial with the columnar body; a bolt hole is formed in the axis of the cylindrical bulge; the handle II comprises a columnar body II; a cylindrical groove I butted with the cylindrical bulge is formed in the inner end face of the columnar body II; a cylindrical groove II is formed in the outer end face of the columnar body II; a through hole is formed in the center of a columnar body connected with the cylindrical groove I and the cylindrical groove II; a spring is arranged in the cylindrical groove II; the inner end of the spring is in contact with the bottom of the groove II, and the outer end of the spring is in contact with a bearing; a bolt runs through the bearing, the spring and the through hole and then is screwed into the bolt hole in the handle I to be fixed; a detachable hand shank is also arranged at each of two ends of the multifunctional wrist force measurer. The multifunctional wrist force measurer is simple in structure, easy to mount and operate, economical, practical and convenient to carry.

Owner:潘峰

A kind of arc spring shock absorber

ActiveCN106481731BExtended service lifeSolving NVH challengesVibration suppression adjustmentsTransmitted powerEngineering

The invention discloses a circular-arc spring shock absorber. The circular-arc spring shock absorber comprises a drive disc as well as a flange and a cover plate which are fixedly arranged on the drive disc, wherein a slide slot is formed between the drive disc and the cover plate; an arc-shaped spring is arranged in the slide slot; and the two ends of the arc-shaped spring are connected with the flange. According to the circular-arc spring shock absorber disclosed by the invention, the arc-shaped spring is arranged in the slide slot between the drive plate and the cover plate, power of the drive disc is transmitted to the arc-shaped spring, power is transmitted to the flange through the arc-shaped spring, and the flange is used for transmitting power to a driven disc; when the arc-shaped spring is compressed to twist in the slide slot, a twisting angle which is twice that of a common shock absorber can be obtained, and torque is as large as that of the common shock absorber, so that twisting rigidity which is only one half that of the common shock absorber is obtained. The invention provides the shock absorber capable of simultaneously meeting requirements of low rigidity and large torque, so that a car transmission system has large torque and low rigidity, and therefore, the NVH problem of the car transmission system is solved.

Owner:CHINA & CANTON CLUTCH

Spline structure integrated with multi-stage vibration absorbing function

PendingCN110594398AEliminate backlashAvoid knocking noiseFlywheelsGearing detailsTorque transmissionMissing tooth

The invention discloses a spline structure integrated with a multi-stage vibration absorbing function. The spline structure integrated with the multi-stage vibration absorbing function comprises a main body spline and a vibration absorbing spline; the positions, corresponding to missing teeth on the main body spline, on spline teeth arranged on the vibration absorbing spline are assembled in a filled and embedded manner to form a complete spline structure in which the spline teeth on the vibration absorbing spline and the spline teeth on the main body spline are uniformly distributed in a non-radial direction; spring components are embedded into a spring grooves in the main body spline and the vibration absorbing spline to be assembled and fixed to the position of a spring groove in a flywheel disc in a corresponding manner and then are connected with the spline teeth arranged on a torque transmission plate to transmit a torque; the torque transmission plate is connected with an inputof a main vibration absorber; and the spline structure is formed to optimize a primary vibration absorbing torque and a secondary vibration absorbing torque of the main vibration absorber. The splinestructure integrated with the multi-stage vibration absorbing function has the advantages that the problem of limited vibration absorbing ability of the main vibration absorber in a whole vehicle is solved, the torsion angle of a whole vibration absorbing system is increased, and the driving comfort of the whole vehicle is improved.

Owner:华域动力总成部件系统(上海)有限公司

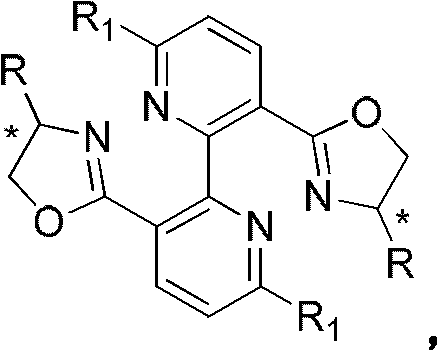

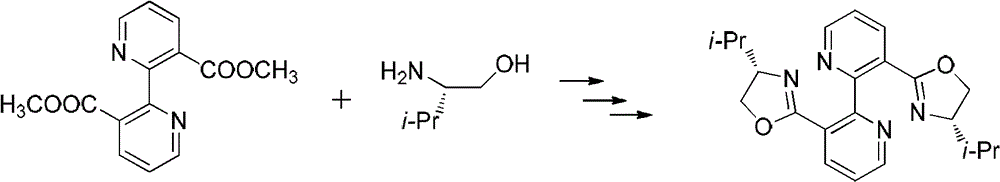

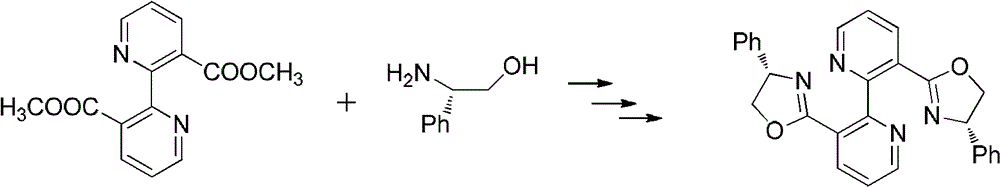

Axially unstable bipyridine-bisoxazoline chiral ligands and their preparation and application

InactiveCN102649789BIncrease the twist angleSmall torsion angleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsStructural formulaBipyridine

The invention provides an axis-unfixed bipyridyl-bis-oxazoline chiral ligand in the technical field of catalysts, and the preparation and the application thereof. The structural formula of the ligand is figured. The invention has the advantages as follows: the method is simple, the yield is higher, and the prepared ligand is coordinated with palladium, copper, silver and zinc, thereby having a fine application prospect in lots of catalytic reactions.

Owner:SHANGHAI JIAOTONG UNIV

Torsional oscillation attenuation device

InactiveCN103502683BIncrease the twist anglePrevent attenuation performance degradationVibration suppression adjustmentsVibration attenuationTorsional oscillations

A torsional vibration attenuation device capable of increasing the torsion angle between an intermediate rotating member and a driven side rotating member when the driven side rotating member is returned to a neutral position from a state of being twisted to the negative side relative to the driving side rotating member, The third elastic member can be greatly elastically deformed to prevent the decrease in attenuation performance. A return spring (36) is provided on the disc (12). The return spring (36) is located on the hub liner (11) relative to the disc (12, 12, 13) When twisted to the negative side, it comes into contact with the sub-plate (16) and bends between the sub-plate (16) and the circular plate (12), thereby facing the positive side end (25a) of the spring receiving window (25) ) and the bending part (27A) exerts force on the sub-plate (16) in the direction in which the gap increases.

Owner:TOYOTA JIDOSHA KK

A high-life cycle torsion-resistant cable for offshore wind power

ActiveCN112908539BHigh tensile strengthIncreased torsional strengthPlastic/resin/waxes insulatorsLiquid organic insulatorsFiberElectrical conductor

The invention relates to the field of power cables, in particular to a high-life cycle anti-torsion cable for offshore wind power, which includes a cable core composed of a plurality of insulated cores, and a tape layer covering the surface of the cable core; The surface is covered with an inner sheath layer; the outer surface of the inner sheath layer is covered with a mixed braiding layer; the outer surface of the mixed braiding layer is covered with an outer sheath layer; the insulated wire core includes a conductor and is covered in An insulating layer on a conductor; the conductor is formed by mixing and winding a plurality of copper wires and a plurality of fiber-copper composite wires; the fiber-copper composite wire includes an organic fiber at the center and one or more layers spirally wound on the outer surface of the organic fiber Copper foil; its fiber-copper composite wire can achieve high-strength tensile and torsion resistance and light weight; the above-mentioned cables are used in the control system of high-power offshore generators or the control system of land wind turbines.

Owner:TBEA DEYANG CABLE CO LTD

Electromagnetically driven two-dimensional scanning micromirrors for laser scanning display

ActiveCN104597596BReduce mutual interferenceIncrease the twist anglePiezoelectric/electrostrictive devicesFlexible microstructural devicesPower flowLaser scanning

The invention relates to an electromagnetically driven two-dimensional scanning micromirror for laser scanning display, which comprises an outer frame, an inner frame arranged in the outer frame, a vertical scanning torsion beam connecting the outer frame and the inner frame, and an inner frame arranged The inner micro-mirror and a pair of magnets, the outer frame has a cantilever, the inner frame is connected to the cantilever of the outer frame through a vertical scanning torsion beam, the cantilever driving coil is arranged on the cantilever, and the inner frame driving coil is arranged on the inner frame. The magnets are respectively arranged on both sides of the cantilever. The magnetic field lines generated by the magnets are perpendicular to the current direction of the cantilever drive coil and the inner frame drive coil. The mutual interference between the two directions is reduced, and a large torsion angle can be easily obtained. In addition, the utilization rate of the magnetic field can be improved, and the driving scheme is simplified.

Owner:苏州工业园区纳米产业技术研究院有限公司

Combination cable for industrial automatic robot arm

InactiveCN113793721AGood flexibilityImprove torsion resistanceFlexible cablesFlexible conductorsPolyesterFiber

The invention discloses a combination cable for an industrial automatic robot arm, and the cable comprises a cable core and a carbon fiber nylon woven outer protective layer coated outside the cable core; the cable core is formed by twisting a power cable, a signal cable and a protective gas pipe; the power cable comprises a first copper conductor, a first polyester film layer wrapped outside the first copper conductor and a chloroprene rubber sheath layer wrapped outside the first polyester film layer; the signal cable comprises a flexible polyvinyl chloride sheath, a shielding layer, a second polyester film layer and a signal core body which are sequentially arranged from outside to inside, and a filling layer is arranged in a gap of the signal core body. The cable is formed by combining the power cable, the signal cable and the protective gas pipe, installation is easy, the defect that the cable is loose during installation is reduced, unified protection is facilitated, the installation space is saved, the flexibility and torsion resistance of the cable are greatly improved, the use requirement can be completely met, the cost performance is high, and conversion of scientific and technological achievements is achieved.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com