Double-layer comb tooth driving MEMS scanning mirror for laser radar and preparation method

A laser radar, scanning mirror technology, applied in the field of micro-electromechanical, can solve the problems of high driving voltage, small scanning frequency and torsion angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

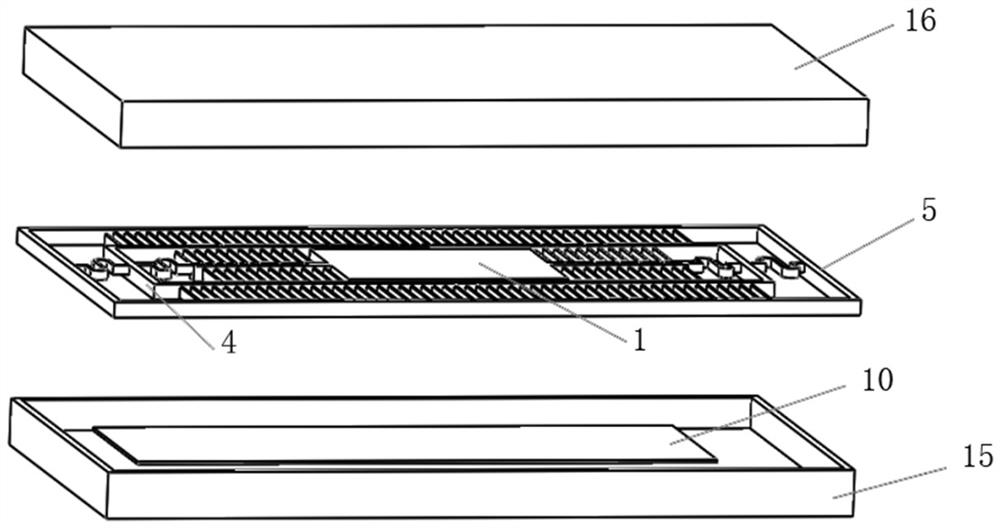

[0063] See Figure 1~2 , a double-layer comb-driven MEMS scanning mirror for lidar, including a transparent glass cap 16, a rotating scanning mirror body and a silicon substrate 15;

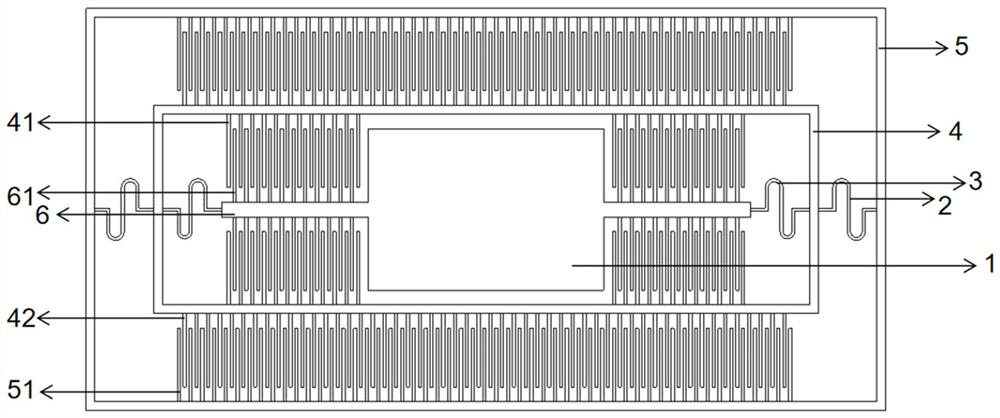

[0064] The body of the rotating scanning mirror is a square structural layer silicon material, and includes a square micromirror 1, a first S-shaped torsion beam 2, a second S-shaped torsion beam 3, a rectangular inner frame 4 and a rectangular outer frame 5;

[0065] The outer frame 5 is coaxially sleeved outside the inner frame 4, and the two ends of the inner frame 4 are respectively connected to the outer frame 5 through the first S-shaped torsion beam 2;

[0066] Both ends of the micromirror 1 are connected to the inner frame 4 through the straight connecting beam 6 and the second S-shaped torsion beam 3, so that the micromirror 1 is movably installed in the middle of the inner frame 4;

[0067] The center of the outer frame 5 is the origin, the length direction of the outer frame 5 is the...

Embodiment 2

[0087] The present invention also includes a method for preparing a double-layer comb-driven MEMS scanning mirror for laser radar, which adopts bulk silicon processing technology and includes the following steps:

[0088] Step (1): Take a double-throw SOI wafer, and include a top silicon layer 100, a middle silicon oxide layer 101, and a bottom silicon layer 102. The layer structure of the double-throw SOI wafer is as follows Figure 7 shown;

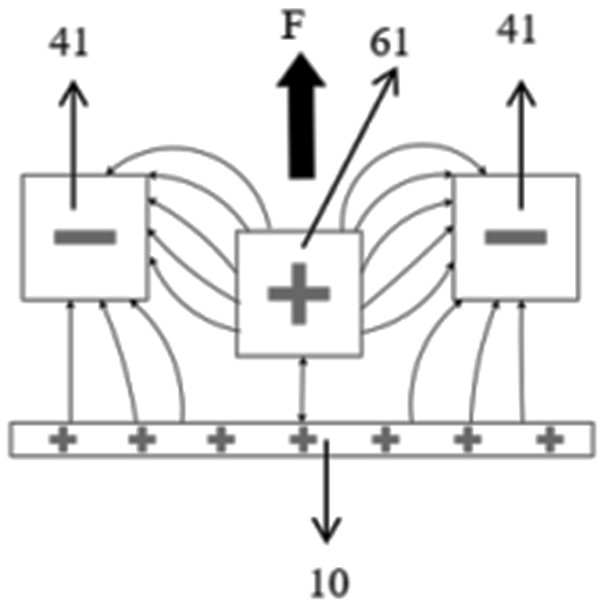

[0089]Deep reactive ion etching is used on the top silicon layer 100 to expose the micromirror 1, the direct connecting beam 6, the first S-shaped torsion beam 2, the second S-shaped torsion beam 3, the inner frame 4, the outer frame 5, Drive combs 61, inner movable combs 41, outer movable combs 42 and fixed combs 51; drive combs 61 and inner movable combs 41 are arranged alternately, outer movable combs 42 and The fixed comb teeth 51 are alternately arranged; as Figure 8 shown.

[0090] Step (2): On the basis of step 1, use a mask ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com