A high-life cycle torsion-resistant cable for offshore wind power

A life cycle, offshore wind power technology, applied in the direction of power cables, power cables for overhead applications, insulated cables, etc., can solve problems such as conductor fatigue and broken cores, low tensile strength, and deformation of insulating cores, and achieve processing Good performance, low cohesive energy of ether bonds, and increased torsion times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

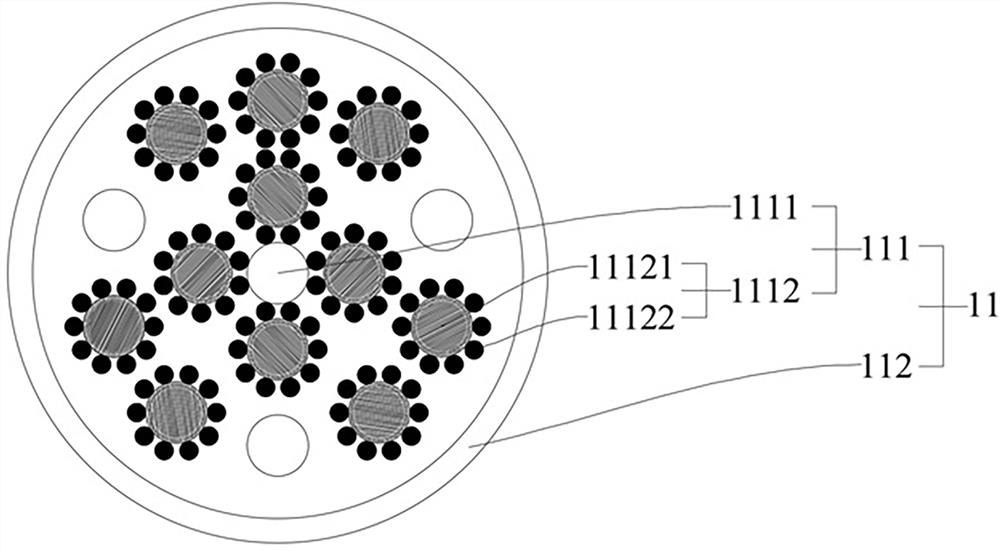

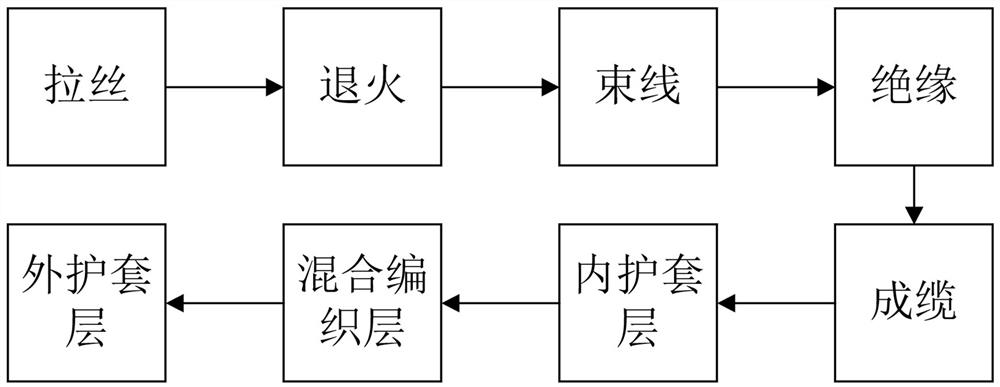

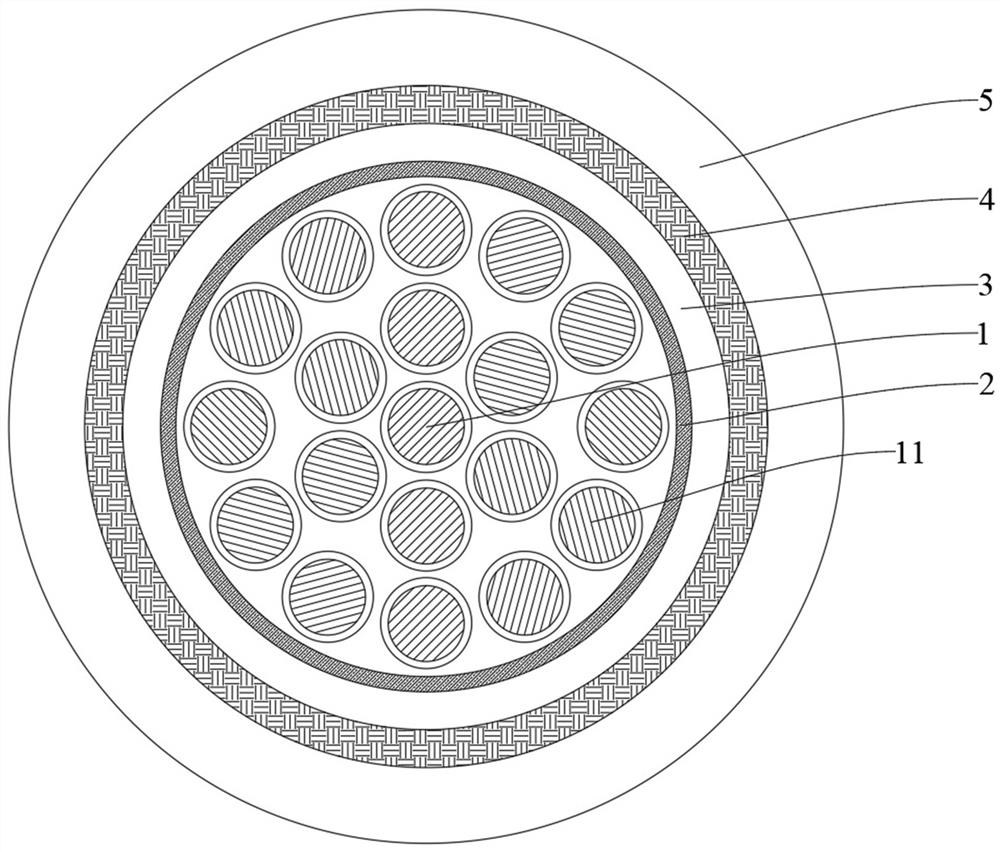

[0051] like figure 1 and figure 2 As shown, a high-life-cycle torsion-resistant cable for offshore wind power includes a cable core 1 composed of a plurality of insulated cores 11, and a tape layer 2 coated on the surface of the cable core 1;

[0052] The outer surface of the tape layer 2 is covered with an inner sheath layer 3; the outer surface of the inner sheath layer 3 is covered with a mixed braided layer 4; the outer surface of the mixed braided layer 4 is covered with an outer sheath jacket 5;

[0053] The insulated core 11 includes a conductor 111 and an insulating layer 112 coated on the conductor 111; the conductor 111 is formed by mixing and winding a plurality of copper wires 1111 and a plurality of fiber copper composite wires 1112;

[0054] The fiber copper composite wire 1112 includes an organic fiber 11121 at the center and two layers of copper foil 11122 spirally wound on the outer surface of the organic fiber 11121 .

[0055] In order to further achieve ...

Embodiment 2

[0076] The organic fiber 11121 adopts the aramid fiber with a fiber count of 50D, and the fiber copper composite wire 1112 adopts a diameter of 0.1mm; the elastomer compound is changed to the following parts by weight Ingredients: 18 parts of polypropylene, 33 parts of styrene-ethylene-butylene-styrene block copolymer SEBS-501, 23 parts of white oil, 5 parts of calcium carbonate, 8 parts of high-impact polystyrene HIPS, 0.2 part of antioxidant 1010, 0.1 part of high molecular weight hindered amine anti-ultraviolet stabilizer 783; described cable core 1 is made of multi-layer insulated wire core 11 according to the same direction of cabling and 30 times the pitch diameter Than cabling; the said wrapping layer 2 adopts double-layer polyester tape materials to overlap and wrap, and the overlapping rate is controlled at 10%; the braiding density of the mixed braided layer 4 is controlled at 60%, The angle is controlled at 20°, the diameter of the metal wire is 0.1mm, and the metal...

Embodiment 3

[0078] The organic fiber 11121 adopts the aramid fiber with a fiber count of 300D, and the fiber copper composite wire 1112 adopts a diameter of 0.25mm; the elastomer compound is changed to the following parts by weight Ingredients: 25 parts of polypropylene, 37 parts of styrene-ethylene-butylene-styrene block copolymer SEBS-501, 27 parts of white oil, 8 parts of calcium carbonate, 13 parts of high-impact polystyrene HIPS, 0.6 parts of antioxidant 1010, 0.3 parts of high molecular weight hindered amine anti-ultraviolet stabilizer 783; said cable core 1 is made of multi-layer insulated wire core 11 according to the same cable forming direction and 40 times the pitch diameter Than cabling; the said wrapping layer 2 adopts single-layer polyester tape material to be overlapped and wrapped, and the overlap rate is controlled at 25%; the braiding density of the mixed braided layer 4 is controlled at 90%, and the braiding angle Control at 65°, the diameter of the wire is 0.3mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com