Combination cable for industrial automatic robot arm

A robot arm, industrial automation technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problem of wear resistance, oil resistance and corrosion resistance, poor insulation and sheath softness, and cables that cannot be worn for a long time. problems, to achieve the effect of increasing the service life, strengthening the electrical continuity, and enhancing the resistance to tilting and swaying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The raw materials for the preparation of the highly flexible soft polyvinyl chloride insulating layer 3 include the following components in parts by weight: 50-80 parts of polyvinyl chloride, 10-30 parts of nitrile rubber elastomer, 3-10 parts of castor oil, 5- 15 parts, 0.2-6 parts of stearic acid.

[0035] The raw materials for the preparation of the flexible polyvinyl chloride sheath 6 include the following components in parts by weight: 45-85 parts of polyvinyl chloride, 7-25 parts of nitrile rubber elastomer, 5-15 parts of castor oil, and 5-15 parts of silicon micropowder , 1-8 parts of stearic acid.

[0036] The neoprene sheath layer 9 is made of special neoprene anti-twist sheath material, and the flexible PVC sheath 6 and the highly flexible soft PVC insulating layer 3 are respectively made of highly flexible soft PVC material, so that the cable can Increase to more than 10 million reciprocating movements, which has the effect of improving the torsional service...

Embodiment 1

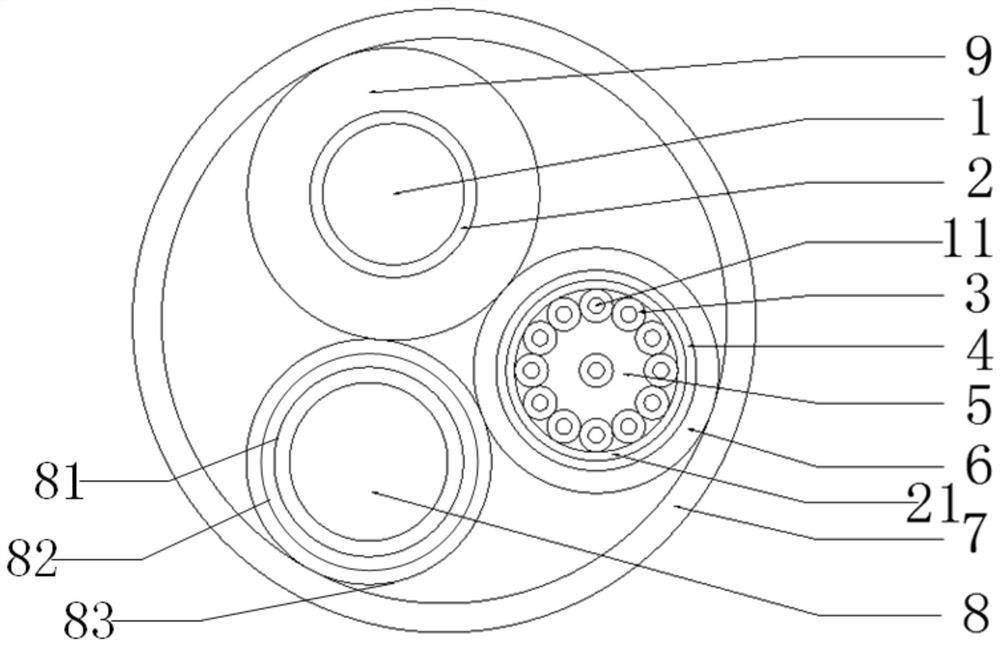

[0039] Such as figure 1As shown, a combined cable for an industrial automation robot arm includes a cable core and a carbon fiber nylon braided outer sheath 7 coated on the outside of the cable core. The cable core is formed by twisting a power cable, a signal cable and a protective gas tube 8. The carbon fiber nylon braided outer sheath 7 is woven from a special carbon fiber nylon bag, which is oil-resistant, corrosion-resistant, wear-resistant, and torsion-resistant.

[0040] The power cable includes a first copper conductor 1 , a first polyester film layer 2 wrapped around the first copper conductor 1 , and a neoprene sheath layer 9 wrapped outside the first polyester film layer 2 .

[0041] The signal cable includes a flexible polyvinyl chloride sheath 6, a shielding layer 4, a second polyester film layer 21 and a signal core arranged in sequence from the outside to the inside. The signal core consists of thirteen second copper conductors 11 according to 1+12 It is combin...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the raw materials for the preparation of the highly flexible soft polyvinyl chloride insulating layer 3 of this embodiment include the following components in parts by weight: 65 parts of polyvinyl chloride, 22 parts of nitrile rubber elastomer, 8 parts of castor oil, 12 parts of silicon micropowder, 1 part of stearic acid.

[0050] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com