Micro reflector array manufacturing method

A technology of a micro-mirror array and a manufacturing method, which is applied in the directions of optical elements, optics, instruments, etc., can solve the problems of high filling factor, high driving voltage, small twist angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

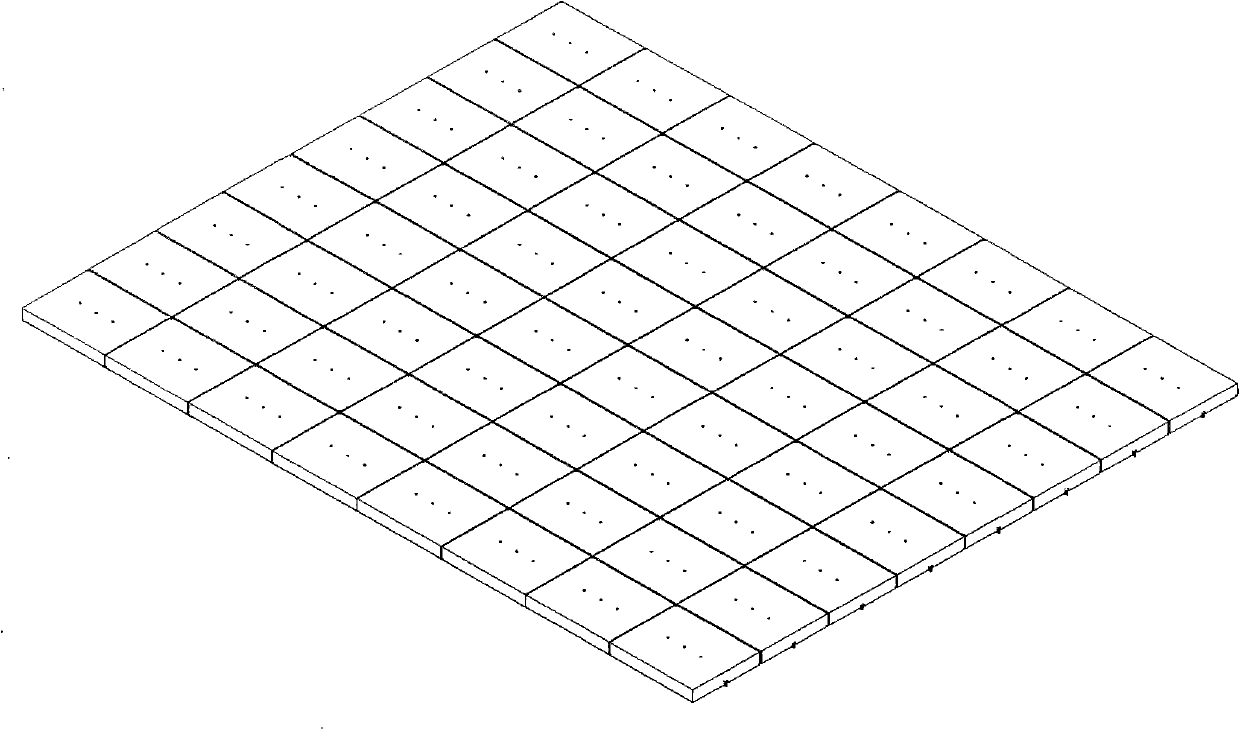

[0034] image 3 It is a top view of a unit in a micro-mirror array. The mirror material is a polished silicon surface. The smooth silicon surface has a high reflectivity to reduce light reflection loss. The surface of the mirror has a supporting pillar release hole.

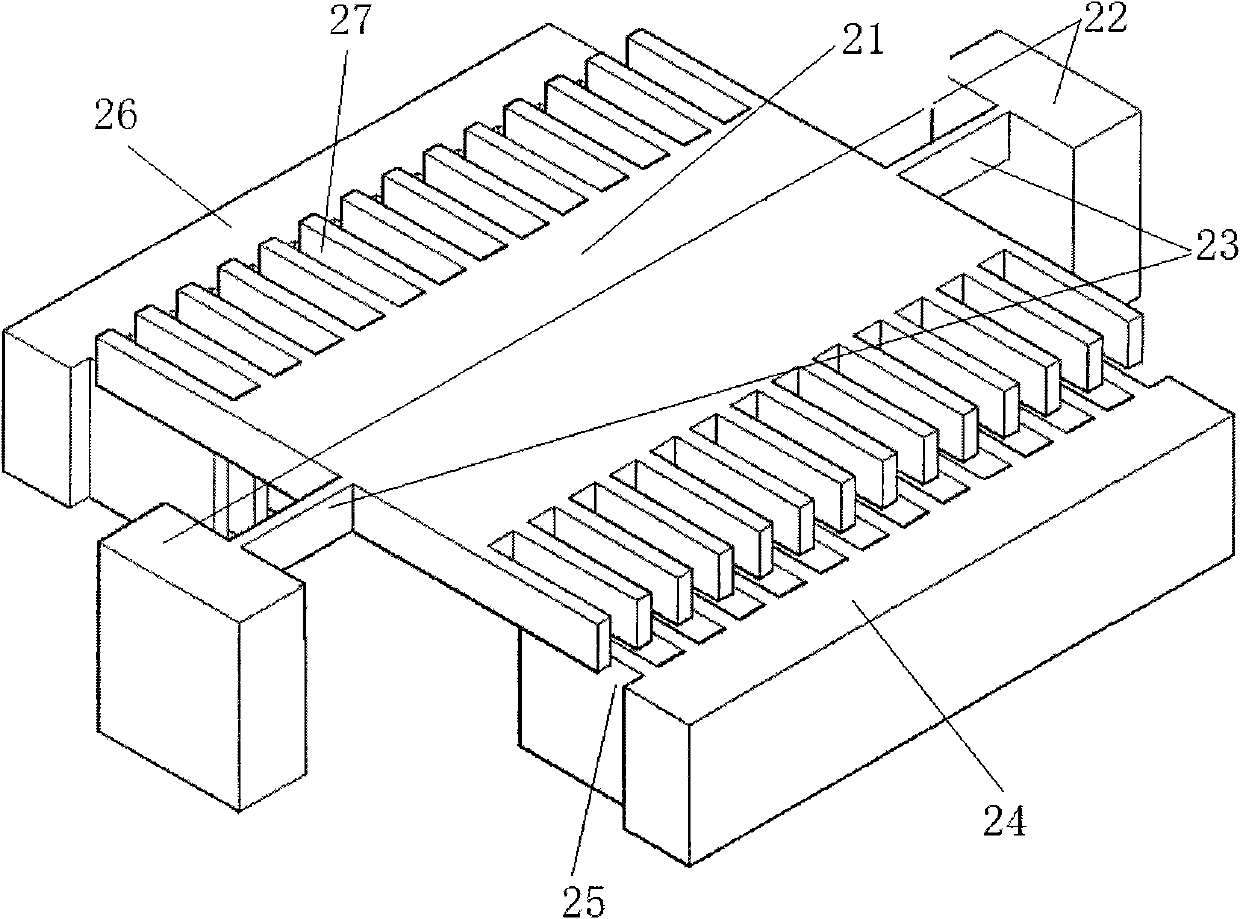

[0035] Figure 4 It is a cross-sectional view of a unit in the micro-mirror array. It consists of a substrate glass sheet 1, a driving structure layer silicon chip 2 and a mirror layer silicon chip 3 bonded together by a wafer bonding process, including a movable driving comb 4, reflecting Mirror 5, bonding metal layer (moving tooth drive electrode) 6, release hole 7, twist beam 8, fixed tooth drive electrode (1) 9, fixed drive comb 10, support column (after release) 11, fixed tooth drive electrode (2) 12, wherein there are metal wiring on the surface of the substrate glass sheet 1 and the driving structure layer silicon sheet 2. The working principle is as follows: the fixed-tooth drive comb 10 is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com