Integral-installation lifting rope-arranging structure of movable-arm tower type crane

A tower crane and integral installation technology, applied in the direction of the crane, the spring mechanism, the hoisting device, etc., can solve the problems of the hoisting wire rope entry angle, etc., and achieve the effect of reducing the entry angle, easy installation, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

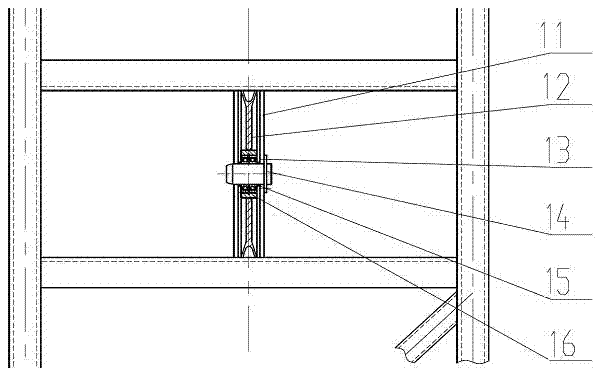

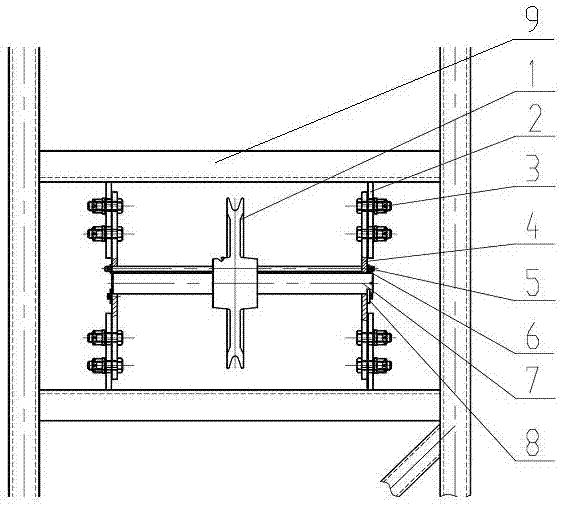

[0023] The present invention is a hoisting and arranging device that can be installed and disassembled as a whole, such as figure 2 As shown, the overall structure is located between the two cross-web bars of the gable frame, including the lifting pulley 1, the long axis 7 of the lifting pulley running through its center, and two side plates 4 respectively connected to the two ends of the long axis 7 of the lifting pulley The lifting pulley 1 is no longer limited by the spacer in the prior art, and can move axially along the major axis 7 of the lifting pulley, thereby realizing the function of arranging ropes.

[0024] In addition, in order to facilitate the installation and connection between the two ends of the long axis 7 of the lifting pulley and the side plate, the side plate 4 is provided with mounting holes that match the ends of the long axis 7 of the lifting pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com