a c 3 S-type sulphoaluminate cement clinker and preparation method thereof

A technology of sulphoaluminate cement and C3S, which is applied in the field of refractory materials, can solve the problems of patent failure, insufficient calcium oxide, and exaggerated calcium oxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

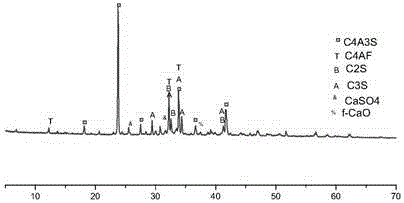

[0046] Clinker chemical composition: CaO49.5%, SiO 2 8.78%, Al 2 o 3 27.95%, Fe 2 o 3 3.07%, SO 3 7.21%, f-CaO3.2%, f-SO 3 0.419%

[0047] Alkalinity coefficient cm: 1.304, aluminum sulfur ratio: 3.6

[0048] CaF 2 Dosage: 0.9%, ZnO dosage: 0.2%

[0049] Firing temperature: 1270°C

[0050] Calculate mineral composition as C 3 S24.63%, C 2 S6.53%, C 4 AF9.33%, C 4 A 3 51.84%

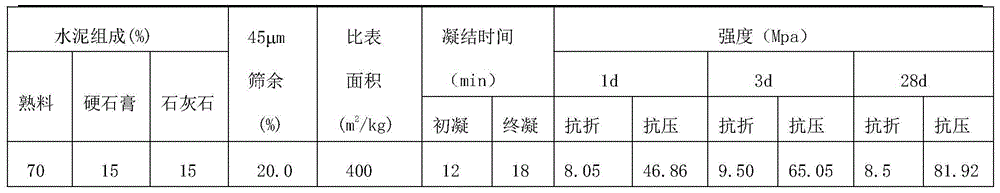

[0051] The parameters and properties of cement prepared with this new type of clinker are shown in the table below. The cement has the characteristics of fast setting, fast hardening, early strength and high strength, especially good strength increase in the later stage.

[0052]

Embodiment 2

[0054] Clinker chemical composition: CaO48.55%, SiO 2 8.58%, Al 2 o 3 28.08%, Fe 2 o 3 2.94%, SO 3 7.33%, f-CaO1.8%, f-SO 3 0.483%

[0055] Alkalinity coefficient cm: 1.29, aluminum sulfur ratio: 3.57

[0056] CaF 2 Dosage: 0.8%, ZnO dosage: 0.1%

[0057] Firing temperature: 1270°C

[0058] Calculate mineral composition as C 3 S27.94%, C 2 S3.46%, C 4 AF9.33%, C 4 A 3 52.27%

[0059] The parameters and properties of cement prepared with this new type of clinker are shown in the table below. The cement has the characteristics of quick setting, early strength, and good later strength increase.

[0060]

Embodiment 3

[0062] Clinker chemical composition: CaO50.8%, SiO 2 9.96%, Al 2 o 3 22.74%, Fe 2 o 3 5.41%, SO 3 5.19%, f-CaO1.5%, f-SO 3 0.152%

[0063] Alkalinity coefficient cm: 1.402, aluminum sulfur ratio: 3.71

[0064] CaF 2 Dosage: 0.5%, ZnO dosage: 0.1%

[0065] Firing temperature: 1270°C

[0066] Calculate mineral composition as C 3 S 35.46%, C 2 S1.74%, C 4 AF16.45%, C 4 A 3 38.46%

[0067] The parameters and properties of cement prepared with this new type of clinker are shown in the table below. Although the C of the clinker 4 A 3 The content is only 38.46%, but the cement still shows the characteristics of rapid hardening and early strength, and good strength increase in the later period.

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com