Frying system of domestic oil press

A technology of oil press and frying material, which is applied in the field of frying material system, which can solve the problems of reducing the sealing of the bottom of the frying pan, inconvenient disassembly and cleaning, and the complicated structure of the bottom of the frying pan, so as to achieve transparent heating of the oil and prevent oil leakage , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

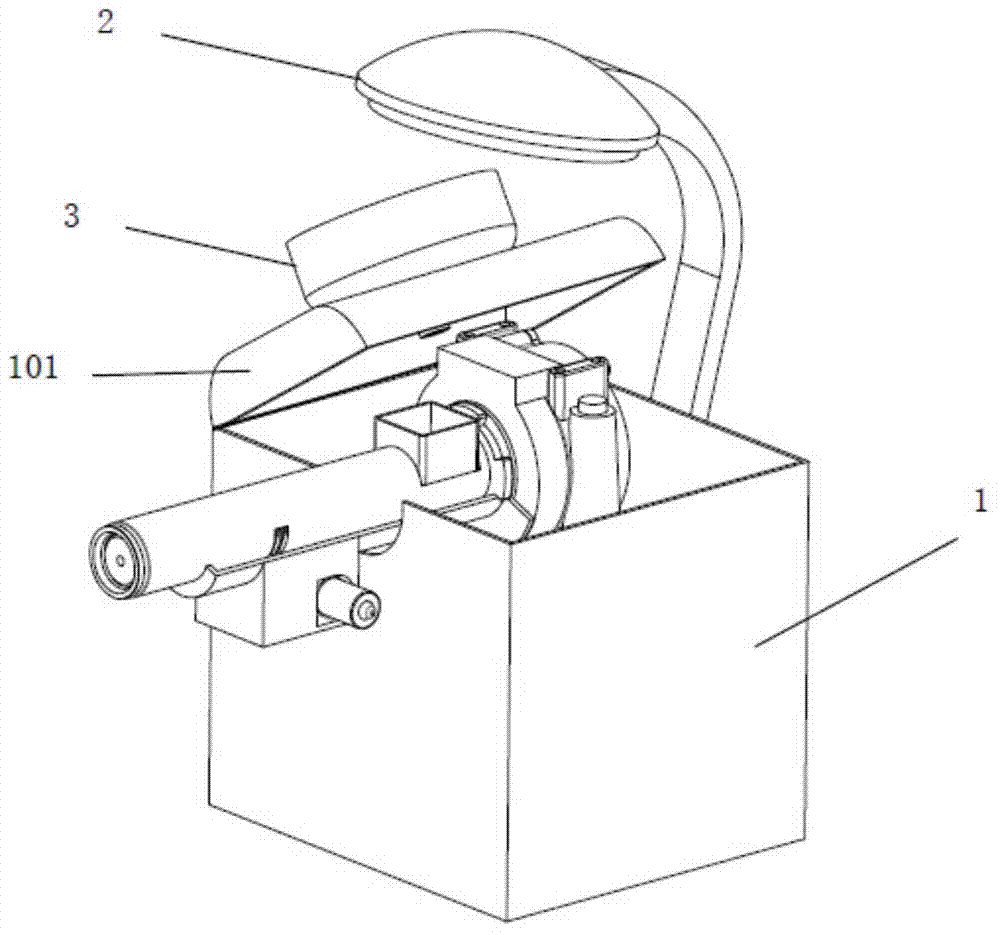

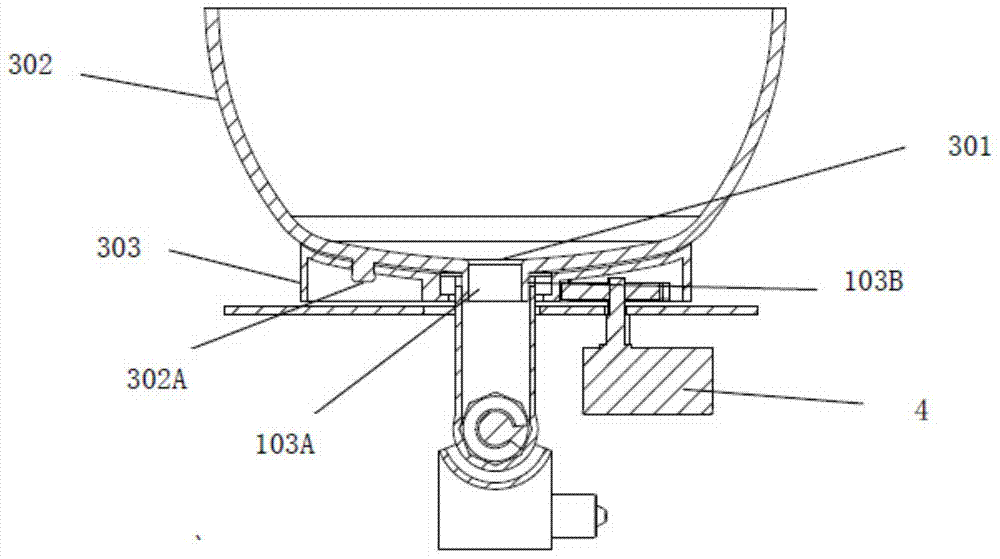

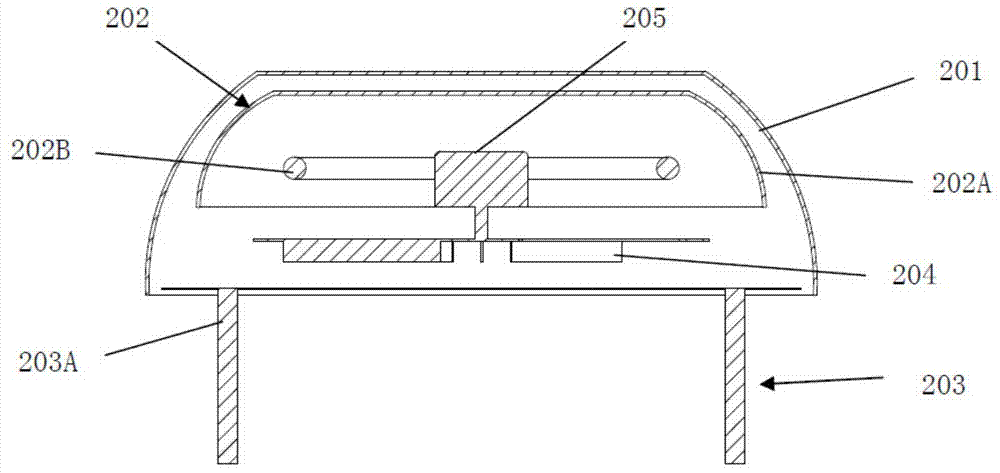

[0041] figure 1 , figure 2 and image 3 , a stir-frying system for a household oil press, comprising: a base 1, a heating structure 2, a frying container 3 with an open top, and a frying motor 4; the bottom of the frying container 3 is provided with a blanking port 301; The heating structure 2 includes a shell, an electric heater 202 located in the shell 201; the electric heater 202 radiates heat downward, and the lower side of the shell 201 is provided with a stirring mechanism 203 extending downward; the frying motor 4 is set in the base 1, the frying container 3 is set on the upper side of the base 2, and the heating structure 2 is covered on the top of the frying container 3; the frying motor 4 is connected with the A transmission mechanism is provided between the frying containers 3; the frying material motor 4 drives the rotation of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com