Deformation joint double-layer shear wall formwork structure and method of using formwork structure to construct double-layer shear wall

A technology for shear walls and deformation joints, applied in the field of double-layer shear wall formwork support structures with deformation joints, can solve the problems of difficult formwork removal, achieve good quality, good economy, and benefit time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

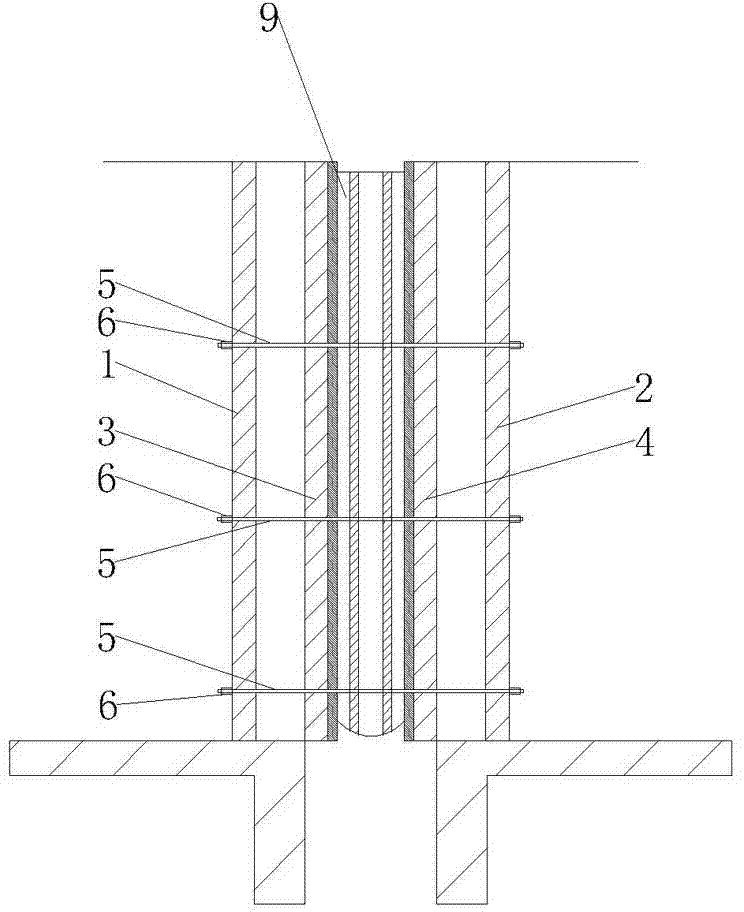

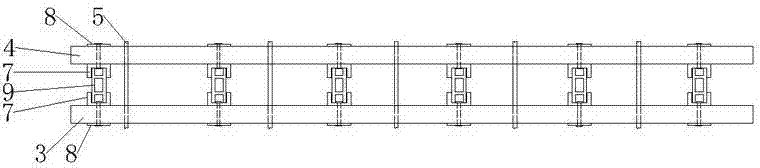

[0011] Such as figure 1 , figure 2 As shown, the deformation joint double-layer shear wall formwork support structure provided by the present invention includes a first outer wooden formwork 1, a second outer wooden formwork 2, a first inner wooden formwork 3 and a second inner wooden formwork 4. An outer wooden formwork 1 is surrounded by the first inner wooden formwork 3 to form the left shear wall pouring operation layer, and the second outer wooden formwork 2 and the second inner wooden formwork 4 are surrounded to form the right shear wall pouring operation layer. A wall-through bolt 5 passes through the first outside wood formwork 1, the second outside wood formwork 2, the first inside wood formwork 3 and the second inside wood formwork 4, and the two ends of the wall-through bolt 5 are fastened with nuts 6. The inner side of the first inner wooden formwork 3 and the inner side of the second inner wooden formwork 2 are vertically provided with a steel chute 7 at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com