Bearing bushing structure

A bearing bushing and bushing technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reduction or even disappearance of interference, loss of centering function of bushing, movement of bushing and shell, etc. , to achieve a wide range of temperature changes, light weight, and reduce the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

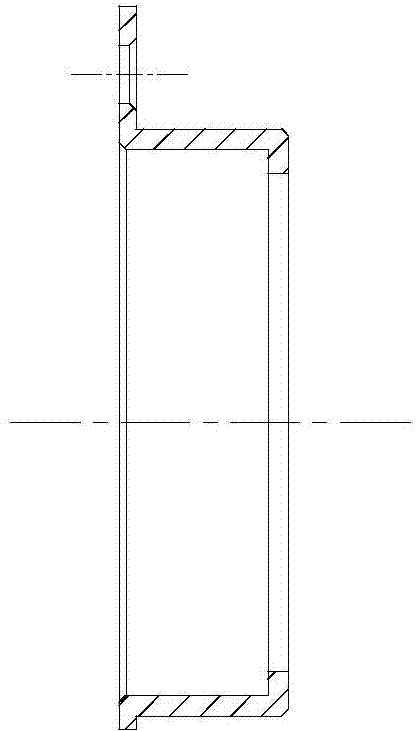

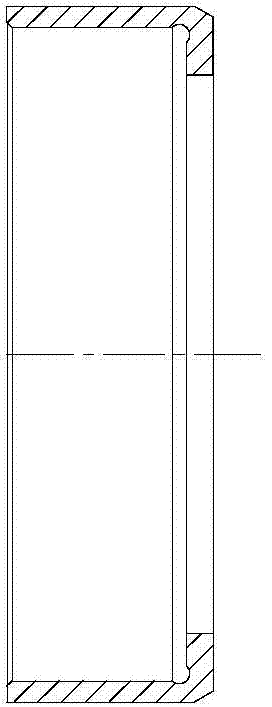

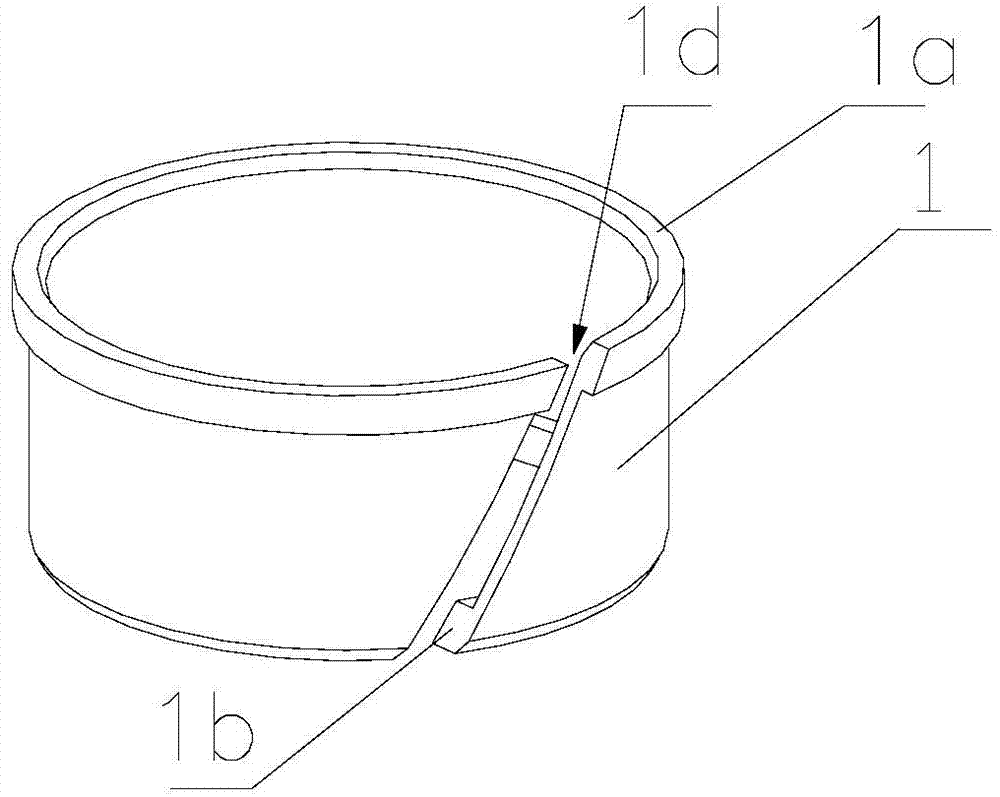

[0011] As shown in the figure, a bearing bushing structure includes a bearing bushing sleeve 1 and the bearing bushing sleeve 1 is provided with a groove 1d that runs through both ends of the bushing sleeve 1. The groove 1d has a bearing bushing in a free state. Large clearance, and when the bearing bush is installed, the bearing bush produces radial elastic deformation. The two ends of the bushing sleeve 1 are provided with flanges 1a, 1b, and the flanges 1a, 1b are located at the two ends of the bushing sleeve 1 and extend to the inner side and the outer side of the bushing sleeve 1 respectively. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com