Straight reciprocating motion mechanism

A technology of linear reciprocating motion and reciprocating mechanism, used in mechanical equipment, transmission elements, transmission devices, etc., can solve the problems of inflexibility and poor stability, and achieve the effects of improving accuracy, good stability and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

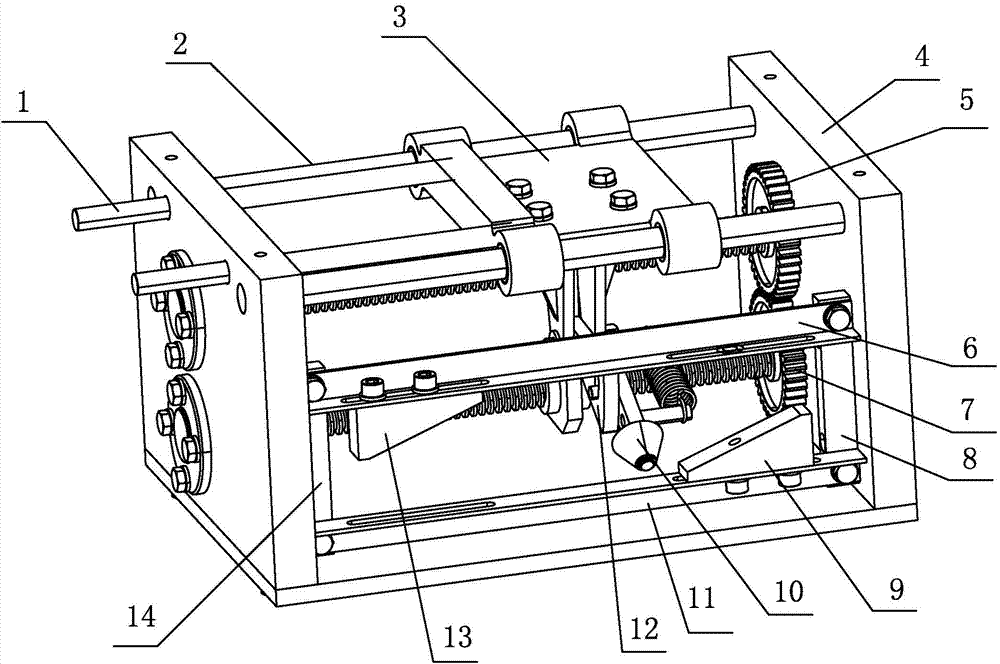

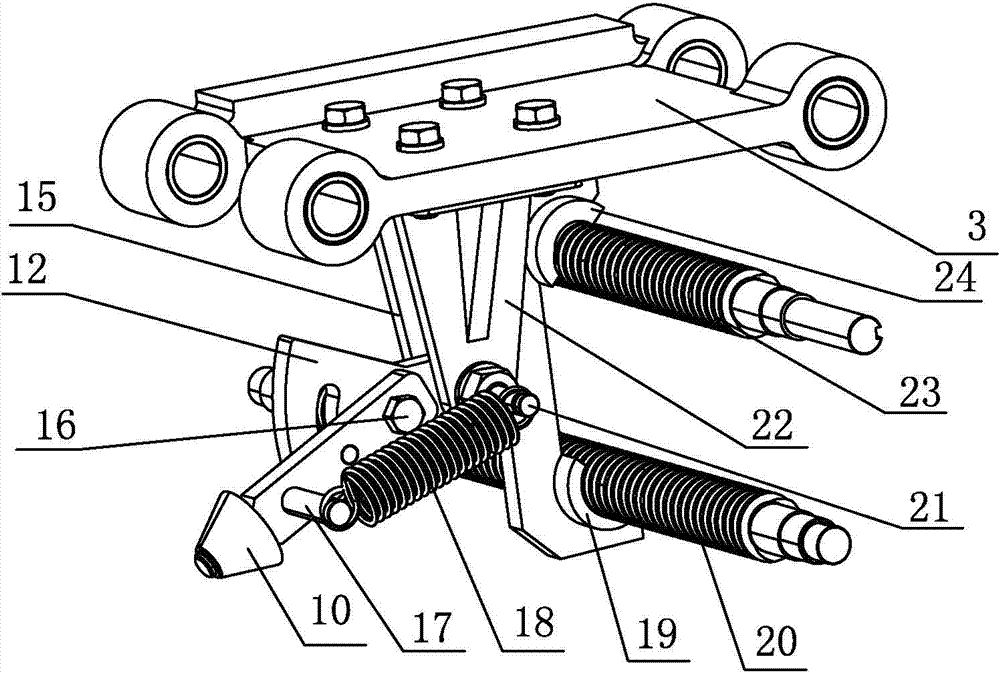

[0020] Such as figure 1 and figure 2 As shown, the present invention includes a support, a reciprocating mechanism and a drive mechanism, and the support includes two support plates 4 arranged at a distance from each other and a support for supporting and fixing the two support plates 4; the reciprocating mechanism includes a first wire Rod 23, the second screw mandrel 20, the first rocker arm 12, the sliding part 3, the slide rail 2, the second rocker arm 25, the spring 18, the left guide block 13, the right guide block 9 and the guide block mounting bracket, the first Both ends of the screw mandrel 23 and the second screw mandrel 20 are respectively supported and installed on the two support plates 4 by bearings, the slide rail 2 is a cylinder and two are arranged in parallel, and the two ends of the slide rail 2 are respectively fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com