Constant volume bomb window

A technology of constant volume bullets and windows, which is applied to the testing of measuring devices, instruments, machines/structural components, etc., to achieve the effects of ensuring safety, improving sealing effects, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

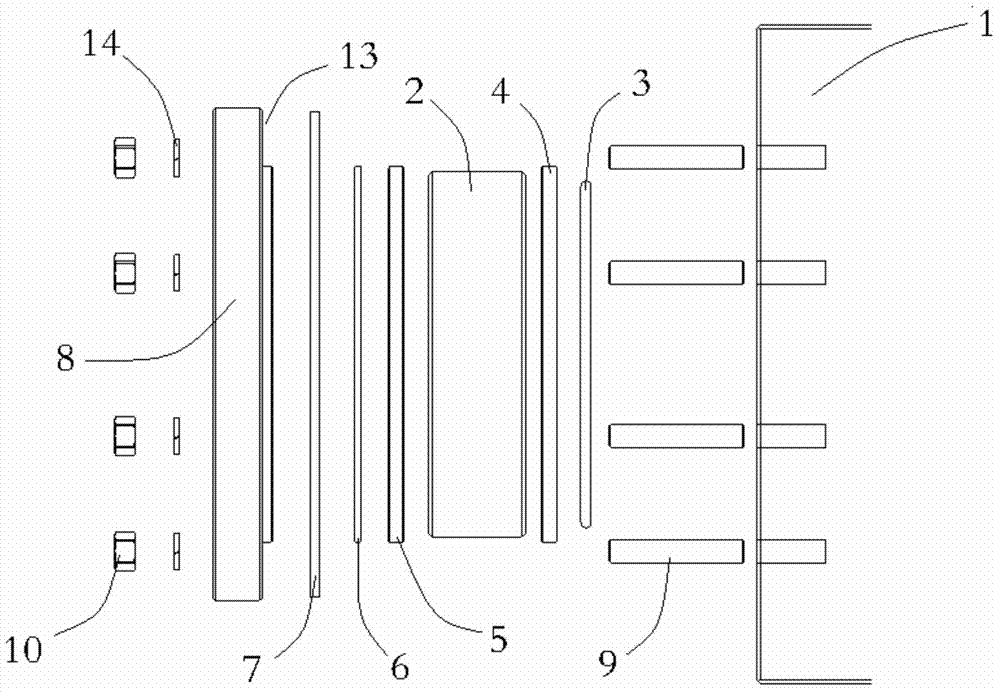

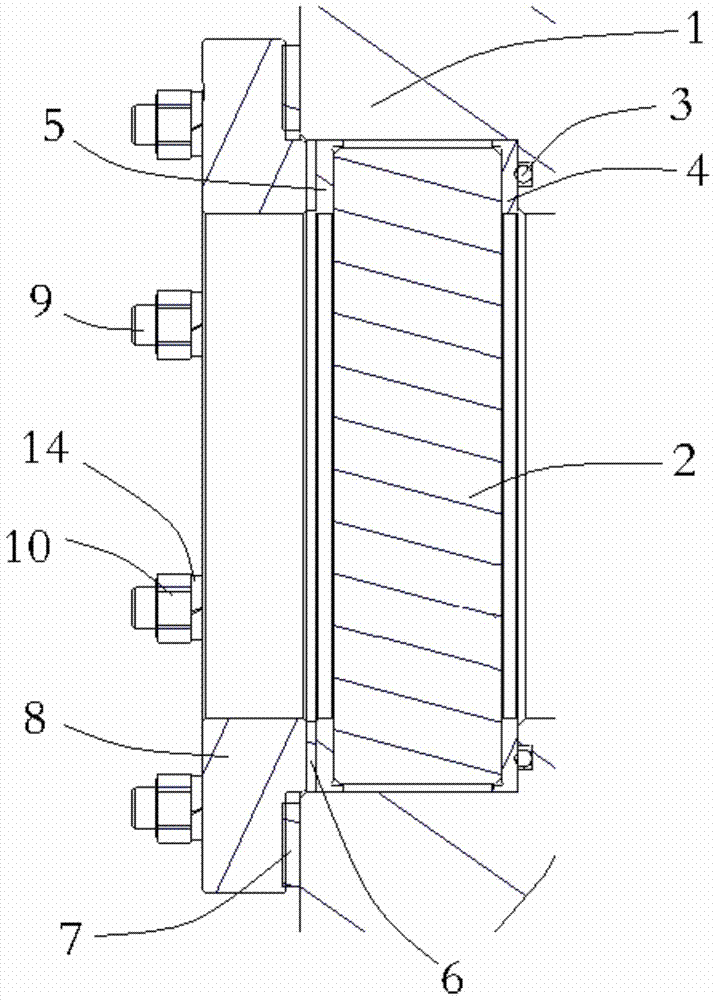

[0022] As shown in the figure, the constant volume bomb viewing window of this embodiment includes a constant volume bomb body 1, an annular glass window 2, an O-shaped sealing ring 3, a first metal gasket 4, a second metal gasket 5, a first rubber sealing gasket 6, The second rubber sealing washer 7, the pressure plate 8, the stud 9 and the nut 10; wherein:

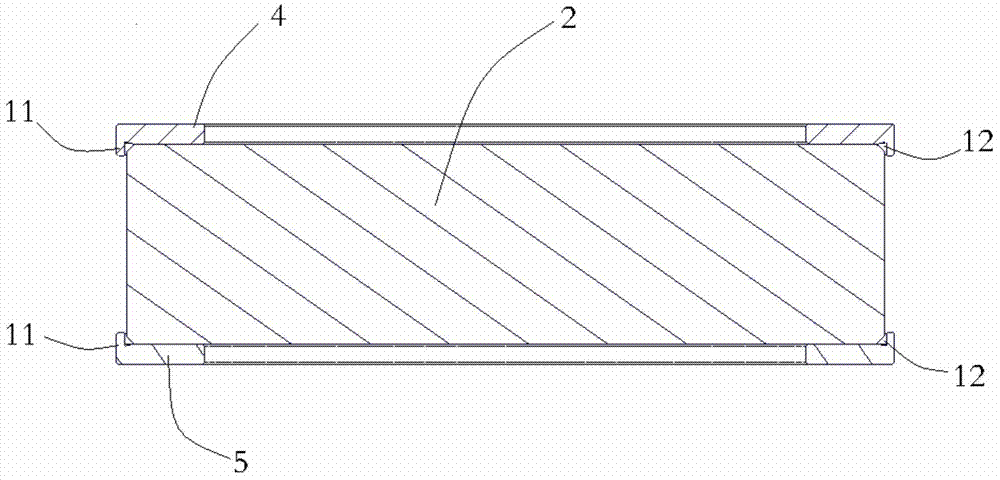

[0023] The first metal washer 4 and the second metal washer 5 have the same structure and are located on both sides of the glass window 2 respectively. The edges of the first metal washer 4 and the second metal washer 5 are provided with an annular boss 11 towards the side of the glass window 2; The inner diameter of the annular boss 11 is slightly larger than the outer diameter of the glass window 2; the annular edge of the glass window 2 is an arc transition, and the bodies of the first metal gasket 4 and the second metal gasket 5 are connected to the annular boss 11. An avoidance recess 12 is provided at the place, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com