Optical imaging lens and electronic device using optical imaging lens

An optical imaging lens and imaging technology, applied in the field of optical lenses, can solve problems such as too small field of view, difficulty in meeting design requirements, etc., and achieve the effects of overcoming aberrations, light and thin structure design, and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

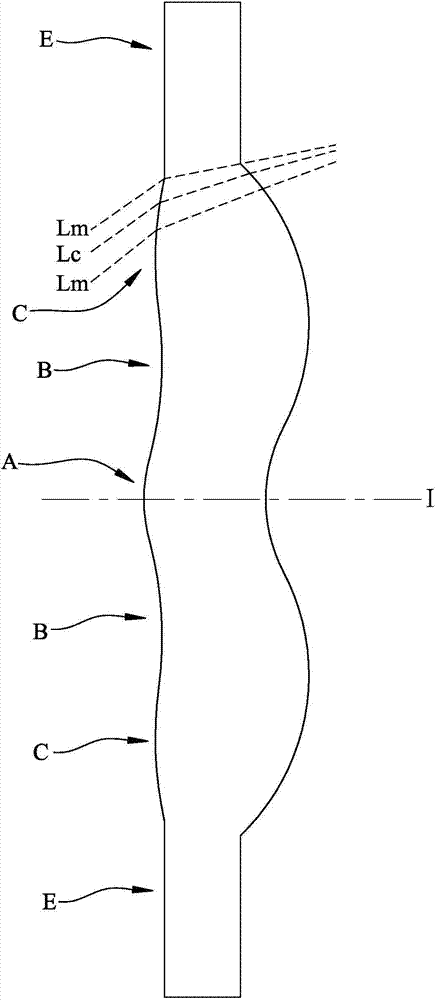

[0110] The expression "a lens has positive refractive power (or negative refractive power)" in this specification means that the lens has positive refractive power (or negative refractive power) in the vicinity of the optical axis. "The object side (or image side) of a lens has a convex surface (or concave surface) located in a certain area" means that the area is closer to the direction parallel to the optical axis than the radially outer area of the area. For "convex" (or "concave"), the figure 1 For example, where I is the optical axis and the lens is radially symmetrical to each other with the optical axis I as the axis of symmetry, the object side of the lens has a convex surface in the A region, a concave surface in the B region, and a convex surface in the C region , the reason is that compared with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com