Electric permanent magnetic chuck control device capable of quick mold changing

A technology of electric permanent magnetic chuck and control device, which is applied in the direction of electrical program control and sequence/logic controller program control, etc., which can solve the problems of increased labor costs, increased mold opening costs, and high precision of mold calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

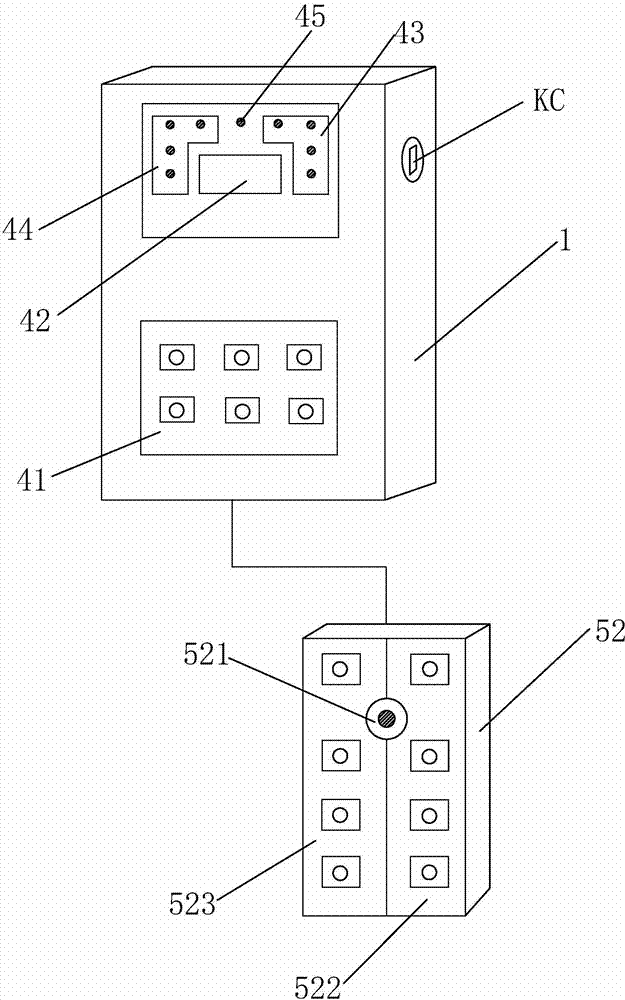

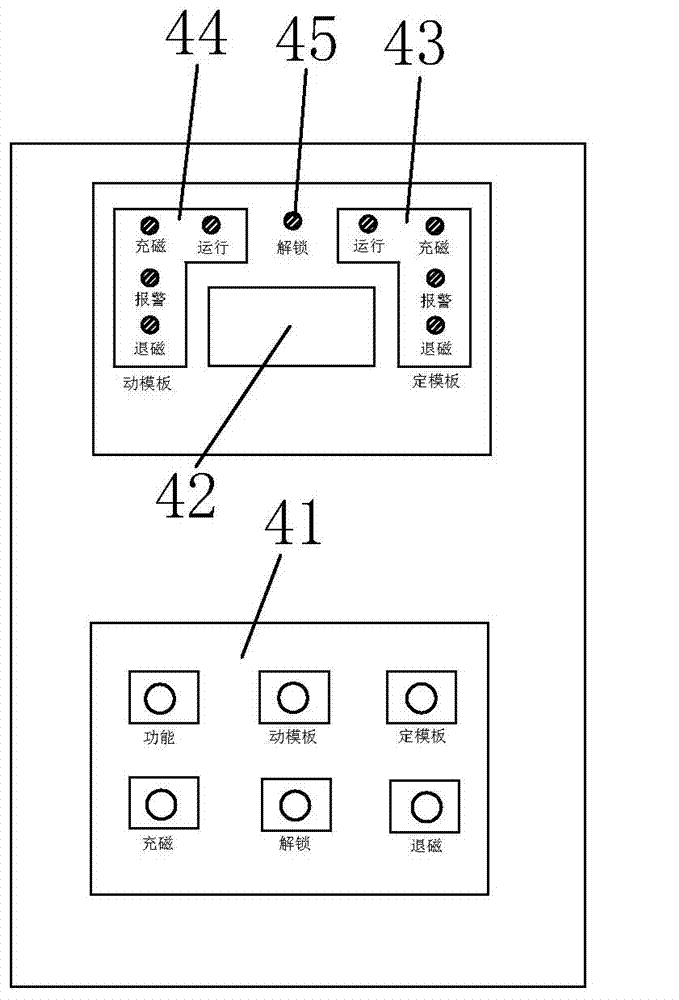

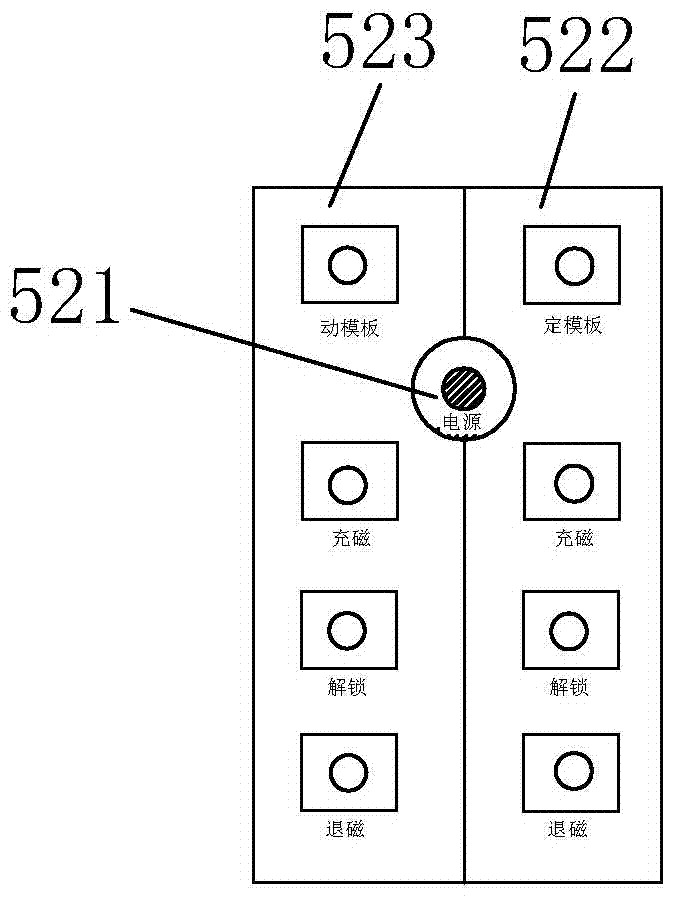

[0025] Such as figure 1 - Figure 10Shown: an electro-permanent magnetic sucker control device for rapid mold change, including a fixed controller 1, a fixed template 2, and a movable template 3, and the fixed controller 1 is electrically connected to the fixed template 2 and the movable template 3 respectively, and is characterized in that: The front of the fixed controller 1 is provided with a button control panel 41, a digital display 42, a fixed template status indicator 43, a moving template status indicator 44, and an unlock status indicator 45; Connect proximity switch sensor 46, temperature sensor 47, magnetic sensor 48, magnetic induction coil 49, magnetic injection molding machine injection platform proximity switch 50, injection molding machine power supply 51, mobile controller 52; described fixed controller 1 side is provided with power supply key Switch KC; the CPU main control circuit of the fixed controller 1 is provided with several circuit channels to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com