Vehicle power transmission device

A power transmission device and vehicle technology, applied in the field of power devices, can solve problems such as power loss and lubricating oil deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

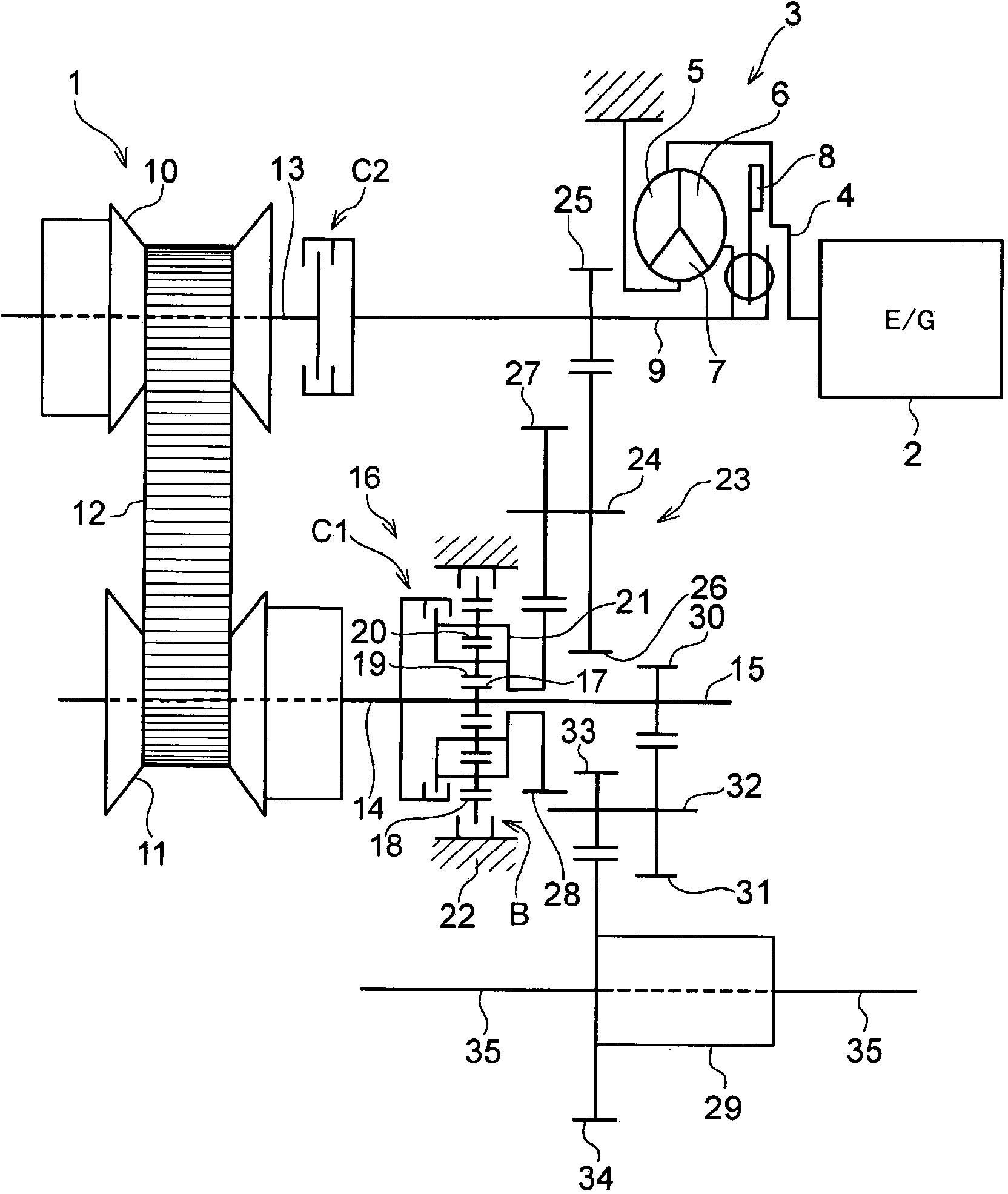

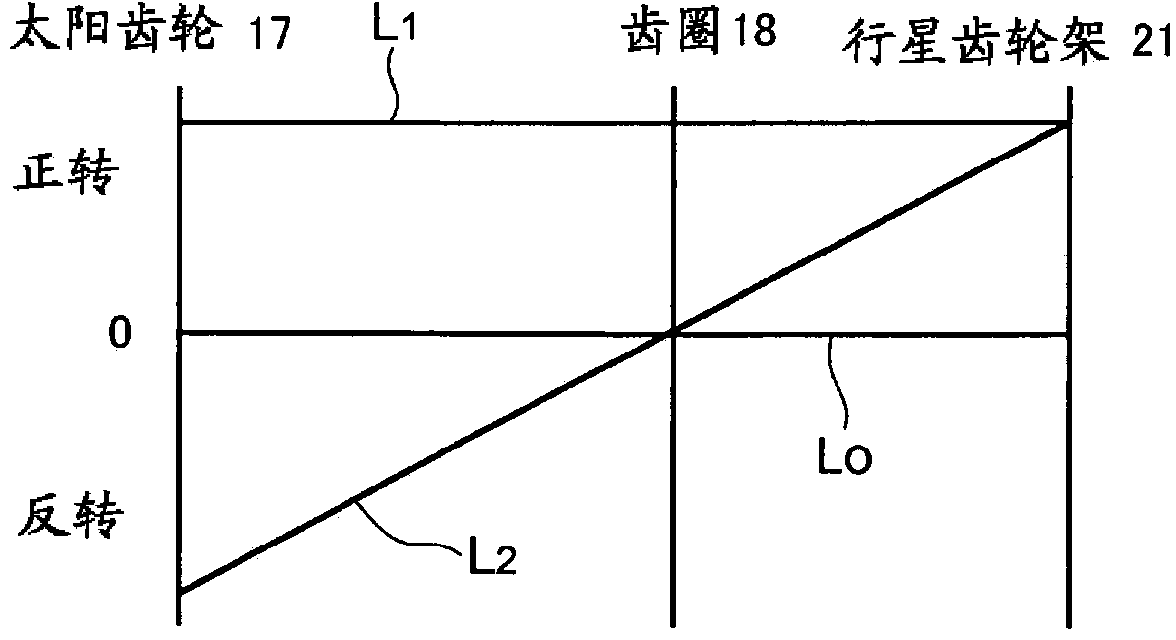

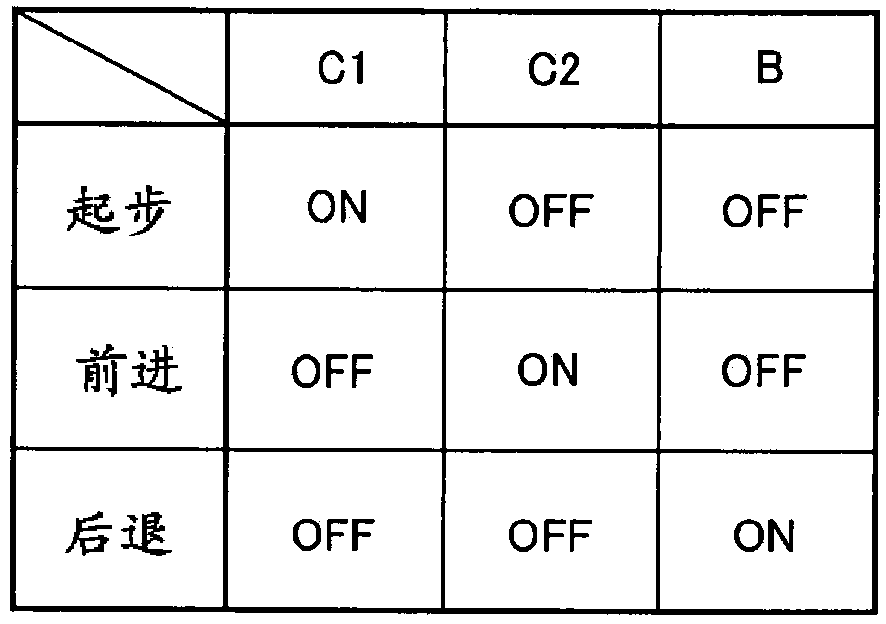

[0052] Next, the present invention will be explained with reference to specific examples. The power transmission device according to the present invention is a device for transmitting power output from a driving power source such as an engine or an electric motor to the driving wheels, and is a device having a speed change function. That is, it is a device generally called a power train or a transaxle. In particular, the device targeted by the present invention is a power transmission device having a continuously variable transmission arranged in parallel between an input shaft and an output shaft and a gear train with a predetermined speed ratio (gear ratio). The continuously variable transmission may also be a belt type continuously variable transmission or a toroidal continuously variable transmission known in the past. The belt-type continuously variable transmission is suitable for power transmission devices mounted on FF vehicles (front-engine, front-wheel drive vehicles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com