Cooling container

A container and cooling part technology, applied in coolers, refrigerated rooms, refrigerators, etc., to achieve high-efficiency cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0044] Hereinafter, the first embodiment of the present invention will be described in detail with reference to the drawings.

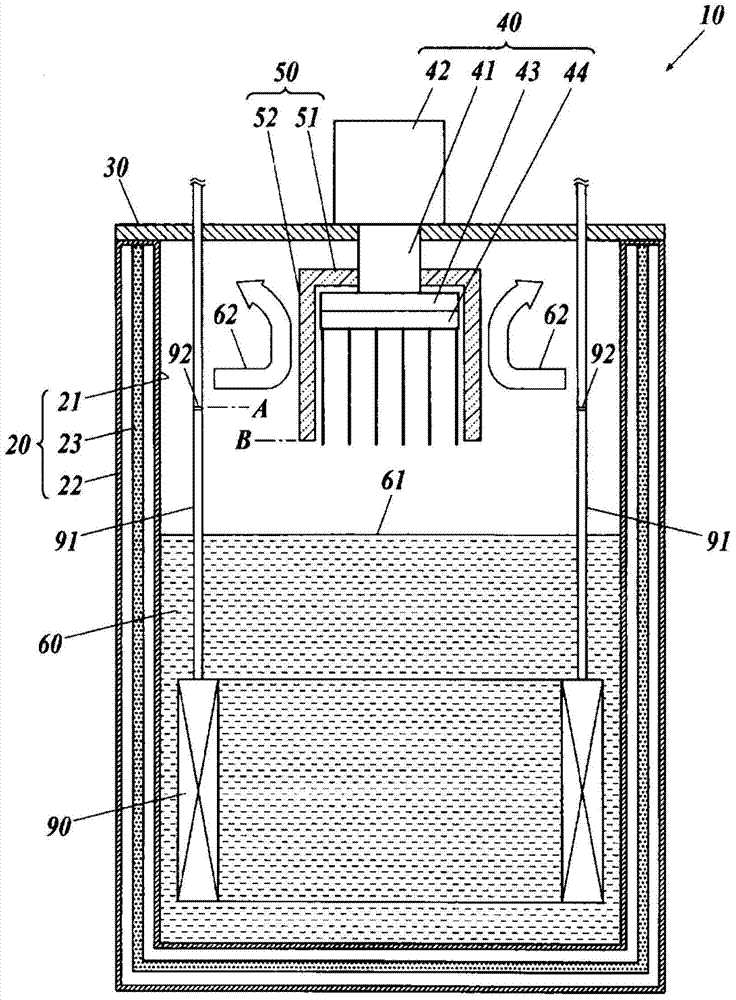

[0045] In this first embodiment, a cryostat 10 as a cooling container for accommodating and cooling a superconducting coil 90 as a superconducting device serving as an object to be cooled will be described. figure 1 is a sectional view of the cryostat 10 along a vertical plane.

[0046] This cryostat 10 has: a refrigerant container 20 which has a vacuum-insulated inner container 21 and an outer container 22 for accommodating liquid nitrogen 60 as a liquid refrigerant and a superconducting coil 90; and a cover 30 capable of sealing the refrigerant. The upper opening of the container 20; the refrigerator 40 as a cooling unit, which cools the liquid nitrogen 60 in the inner container 21; refrigerant gas; and a pair of current wires 91 , 91 for each phase of the superconducting coil 90 for conducting electricity between the superconducting coil 90 and th...

no. 2 Embodiment approach

[0096] Hereinafter, a second embodiment of the present invention will be described in detail with reference to the drawings.

[0097] Figure 5 It is a cross-sectional view along a vertical plane of a cryostat 10C according to the second embodiment.

[0098] This cryostat 10C differs from the cryostat 10 in that it has a new partition wall portion 93 surrounding each current lead 91 . Hereinafter, only the differences between the cryostat 10C and the cryostat 10 will be described, and the same reference numerals will be assigned to the same structures, and repeated description will be omitted.

[0099] As described above, each current lead 91 has the partition wall portion 93 surrounding the current lead 91 .

[0100] The partition wall portion 93 is a cylindrical body made of a heat insulating material into which the current lead 91 is inserted with some play, and its upper end is attached to the lower surface of the cover body 30 by bonding or the like, and supported in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com