A corn harvester and a method for harvesting corn using the corn harvester

A harvester, corn technology, applied in the direction of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high harvest loss rate, high ear loss rate, corn kernel fall off, etc., achieve simple maintenance, reduce harvest loss rate, Header light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

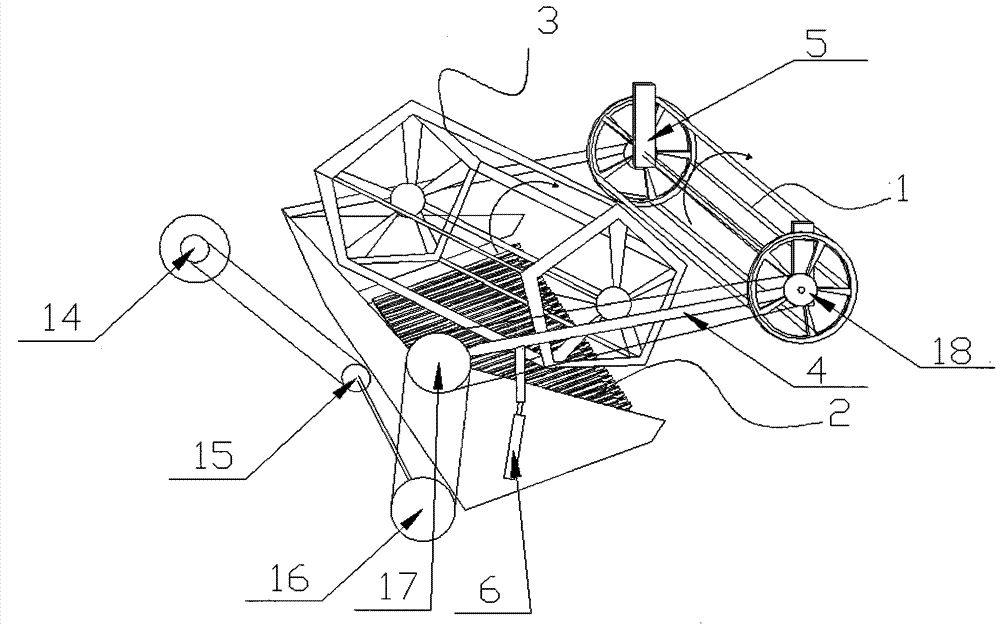

[0038] Such as Figure 1-2 As shown, a corn harvester includes a header, which is connected to the corn harvester by a bridge, characterized in that: the fixed connection on the header is useful for cutting off the upper part of the corn stalk Ear upper cutting mechanism 1. Ear lower cutting mechanism used to cut off the under ear part of corn stalks, a gathering mechanism used to gather corn stalks with corn ears 3. Guide shunting to prevent corn from falling when the ear lower cutting mechanism cuts Mechanism 2. A conveying mechanism for conveying the straw with ears and a threshing mechanism for threshing. The upper ear cutting mechanism 1, the lower ear cutting mechanism, the gathering mechanism 3, the conveying mechanism and the threshing mechanism are all driven by the engine of the corn harvester Drive through the transmission mechanism.

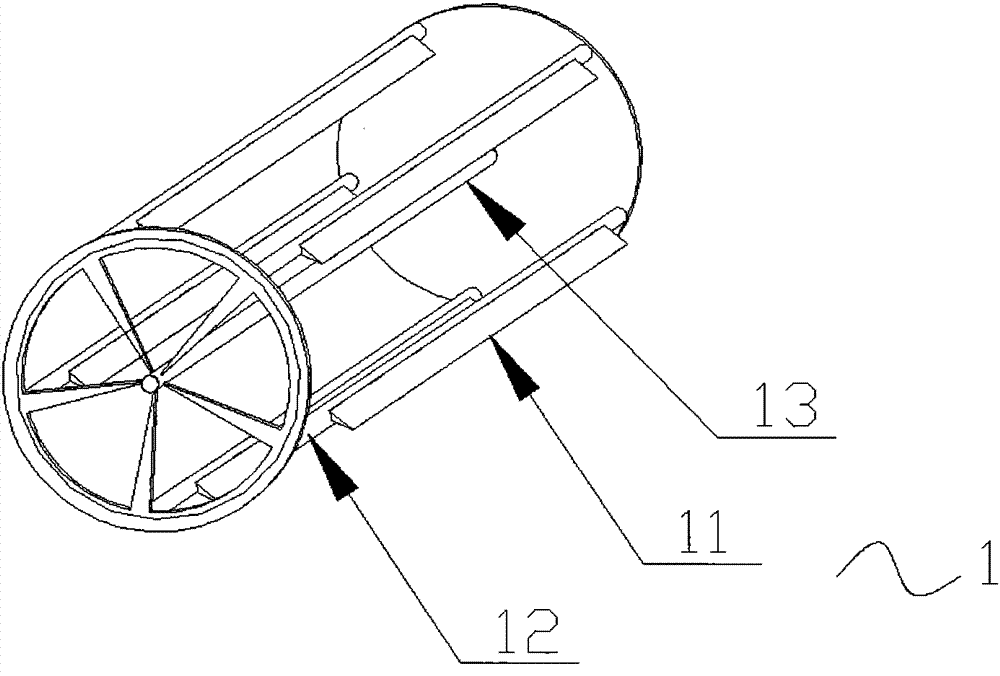

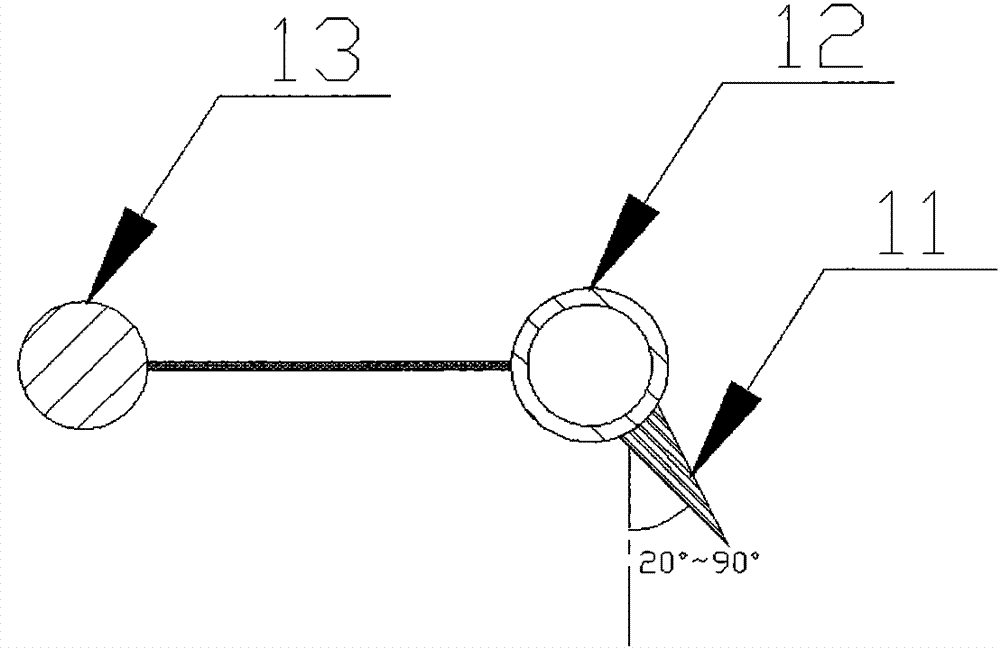

[0039] The ear upper cutting mechanism 1 includes a rotating shaft 13 which is arranged horizontally and perpendicular to the forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com