Waste heat recovery steam cabinet

A waste heat recovery and steaming cabinet technology, which is applied in the field of steaming cabinets, can solve problems such as rising ambient temperature, polluting the environment, and large condensed water, and achieves the effects of excellent performance, energy saving, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

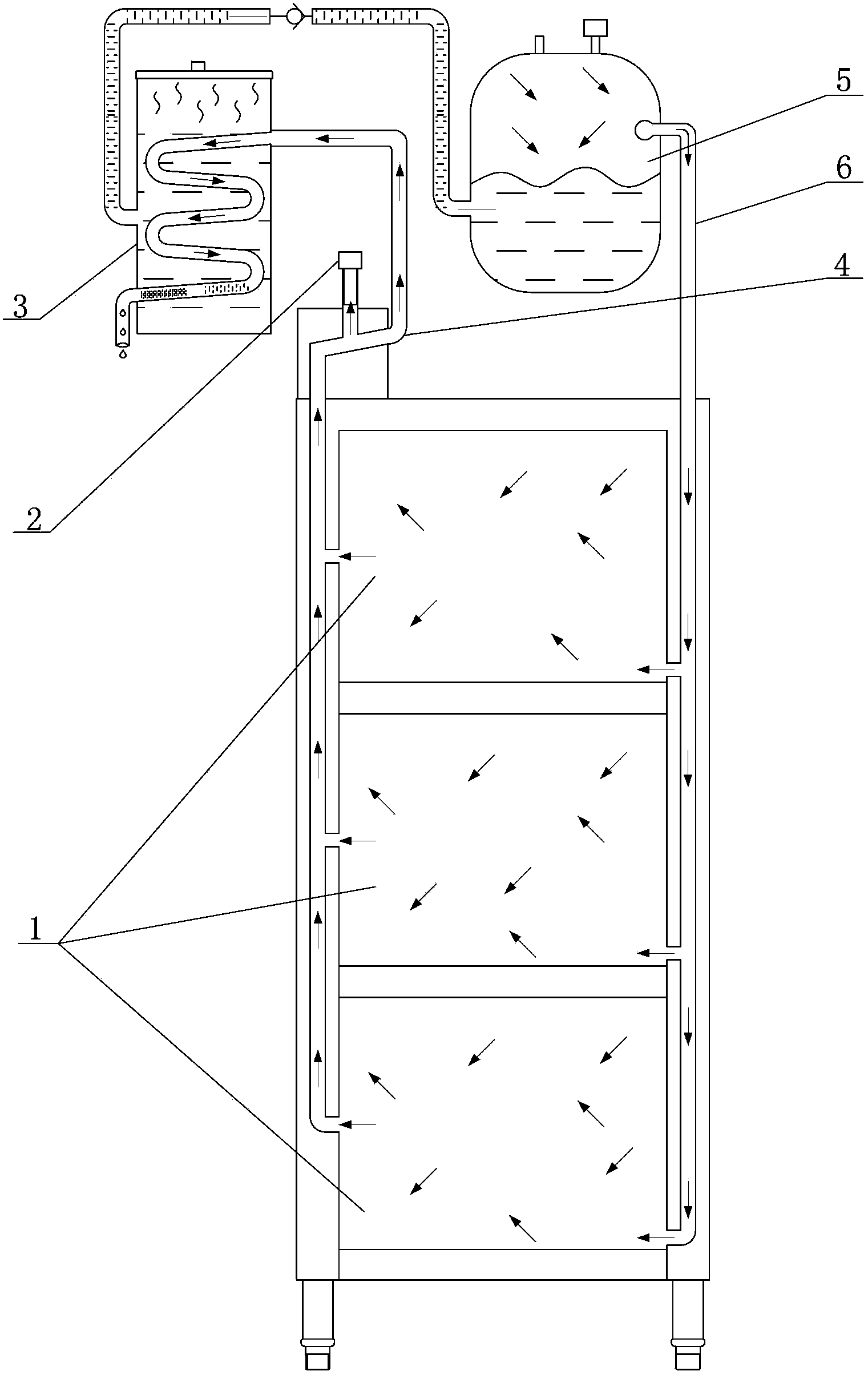

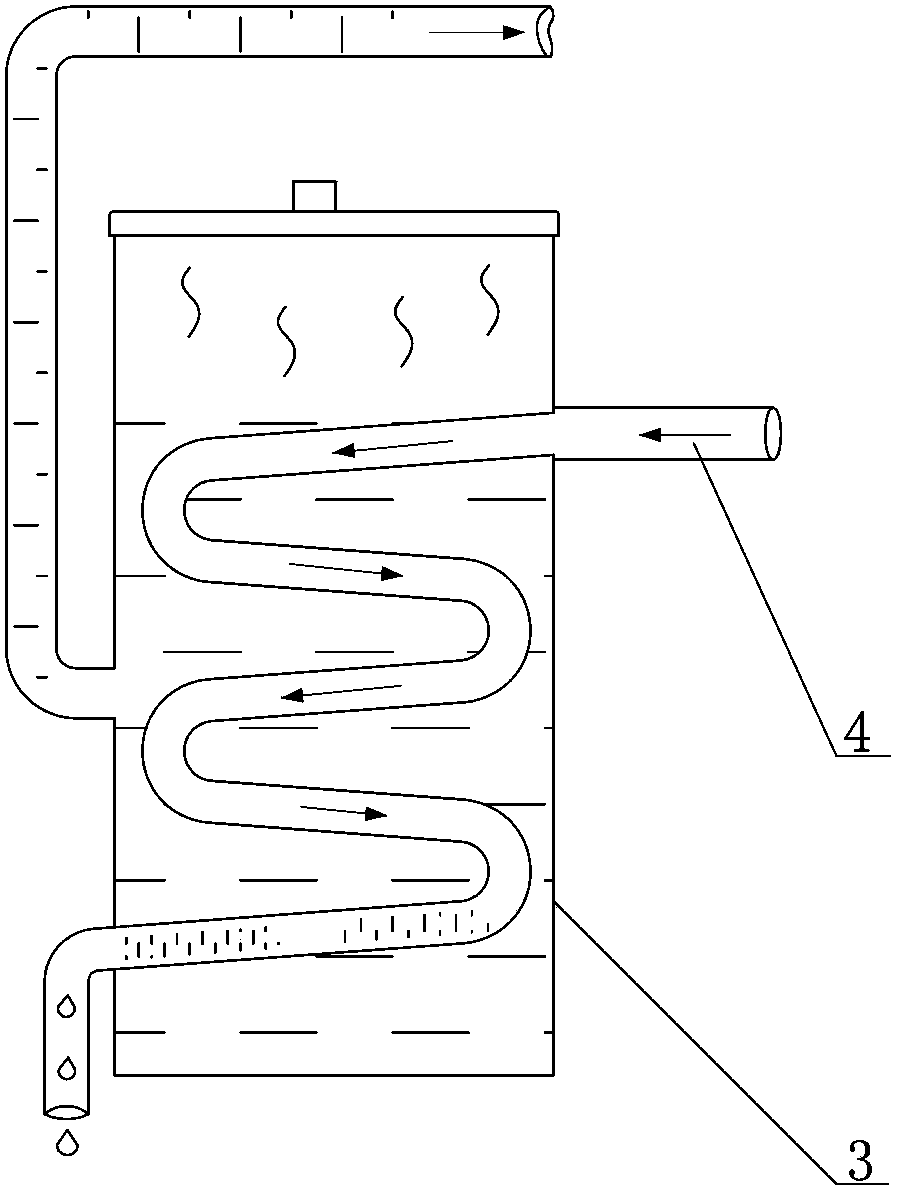

[0017] The steam cabinet with waste heat recovery of the present invention includes a cabinet body and a cavity 1 inside the cabinet body, an air intake pipe 6 is arranged on one side of the cabinet body, and an exhaust pipe 4, an air inlet pipe 6 and an exhaust pipe are arranged on the other side 4 communicate with the cavity 1 respectively, the intake pipe 6 communicates with the steam generator 5, the exhaust pipe 4 passes through the inside of the heat exchange tank 3, and the inside of the heat exchange tank 3 communicates with the steam generator 5 through a water pump and a water inlet pipe. Water is stored inside the heat exchange tank 3 .

[0018] The exhaust pipe 4 is provided with a pressure relief valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com