A configuration structure of special hoisting equipment for copper wire drawing machine and solid wire reel in copper wire workshop

A lifting equipment and configuration structure technology, which is applied in the field of hoisting equipment configuration structure for large drawing machines and dense solid wire reels in copper wire workshops, can solve the problems of increased forklift transportation volume, inconvenient operation, large tonnage, etc. The transportation distance of the forklift, the compact layout, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

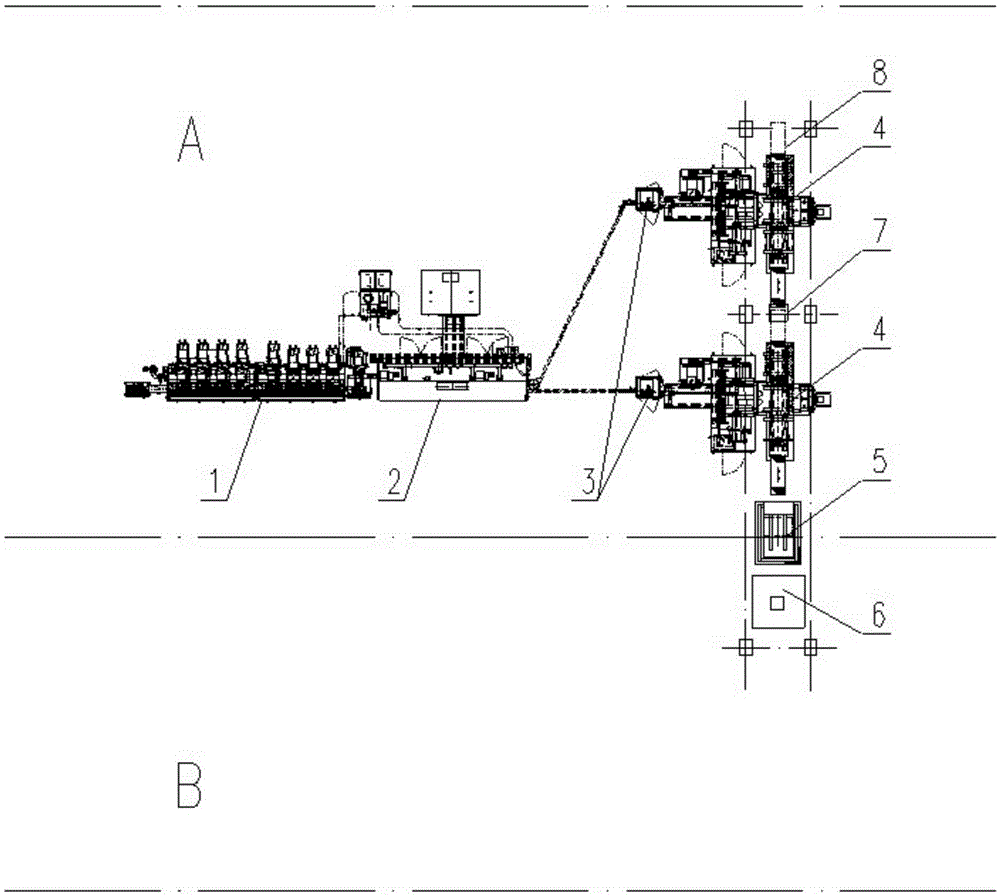

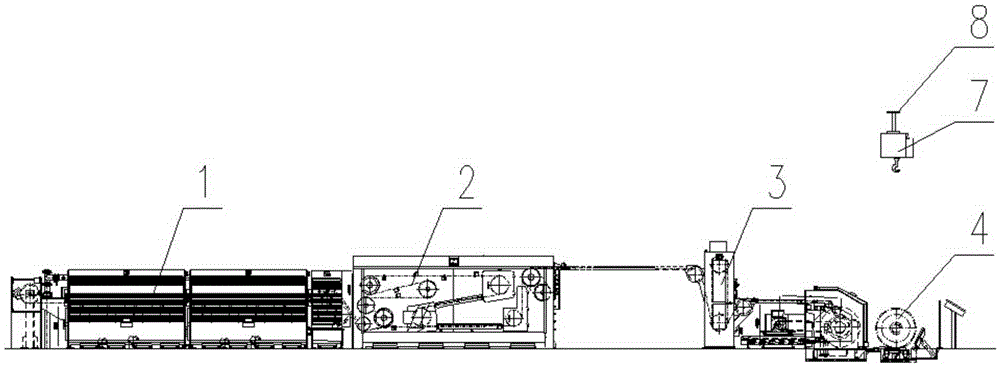

[0016] combine figure 1 , the present invention is a production line equipped with special lifting equipment for large drawing machines and dense solid wire reels in copper wire workshops. It is arranged in the production span A, and the winder 5 and the ground balance 6 are arranged in the adjacent finished span B, so that the equipment forms a cross-span configuration between the two spans. A single track 8 and a small special-purpose electric hoist 7 are arranged above the center line of the ground balance 6, and the special-purpose electric hoist is used to complete the hoisting, rolling, weighing and other work of the reel and complete the cross-span transportation. During production, the copper rod enters the multi-mode wire drawing machine 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com