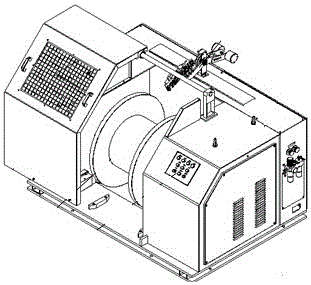

A double-station vertical wire take-up machine

A double-station and wire take-up technology, applied in the field of wire take-up, can solve the problems that restrict the manufacturer's on-site management, equipment investment and operation safety, and achieve the advantages of simple and safe machine operation, high degree of automation, and reduced time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

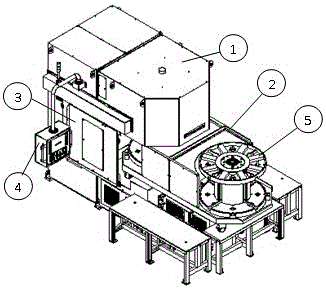

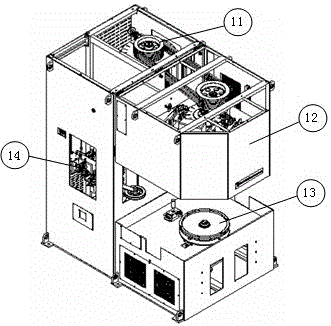

[0026] A double-station vertical wire take-up machine, which includes a take-up main machine 1, a double-station turntable 2, a safety door 3, an electric control mechanism 4 and a frame. Lifting mechanism 13, cable arrangement mechanism 14 and main frame 12, main motor transmission mechanism 11 is provided with main motor 111, speed reducer 112, belt transmission mechanism 113, brake disc 114, brake 116 and dial plate 116, main motor 111 passes through The belt transmission mechanism 113 drives the speed reducer 112, and the speed reducer 112 drives the dial plate 116 to rotate; Top tight with detachable spool wheel 5.

[0027] The I-shaped wheel lifting mechanism 13 is provided with an oil cylinder 131, a telescopic sleeve 132, a rotating shaft 133, a travel switch 134 and a hydraulic pump, and the hydraulic pump controls the oil cylinder 131 to lift the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com