Closed tank system

A fuel tank and tank body technology, applied in the direction of charging system, arrangement combined with internal combustion engine fuel supply, machine/engine, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

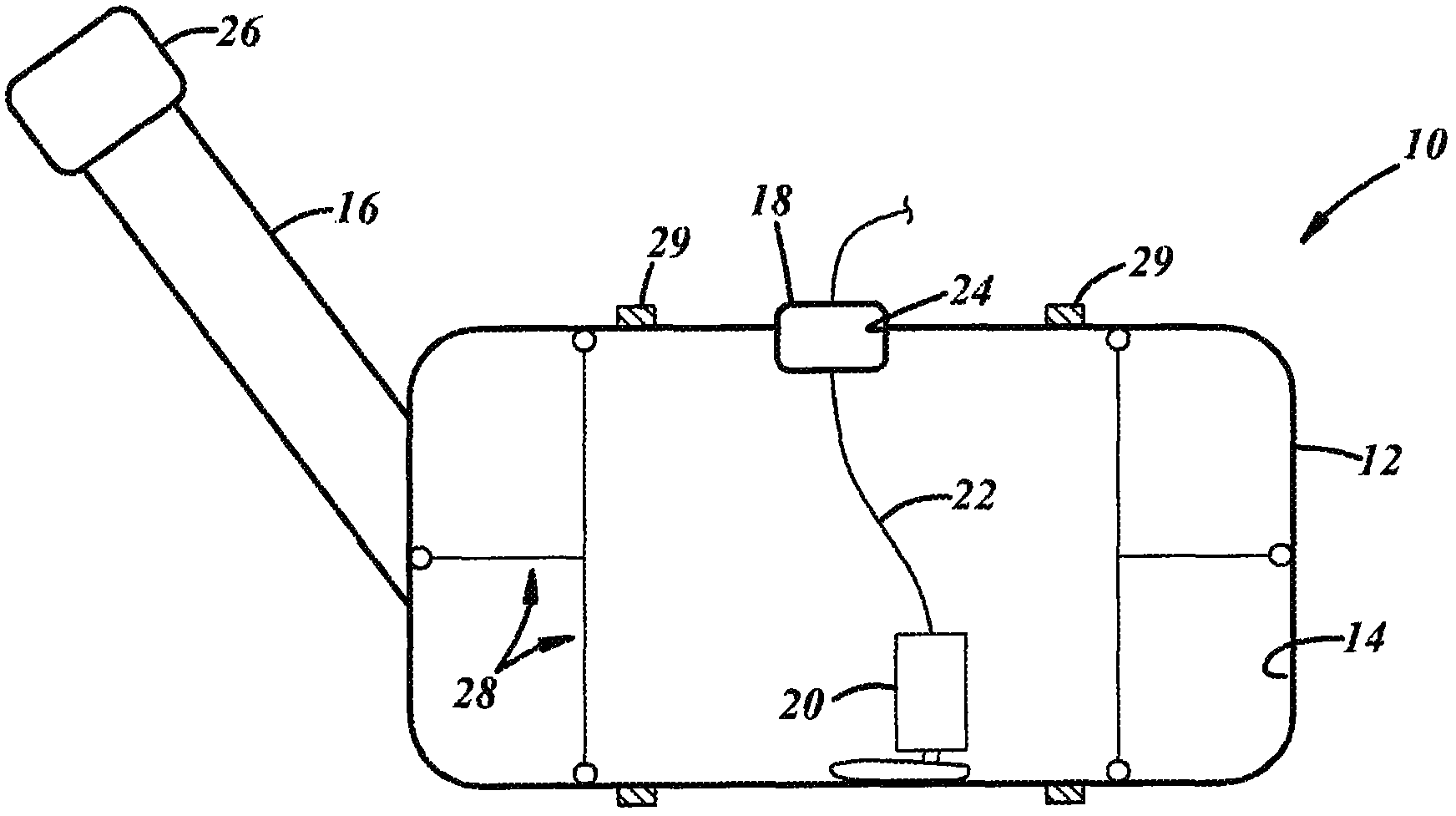

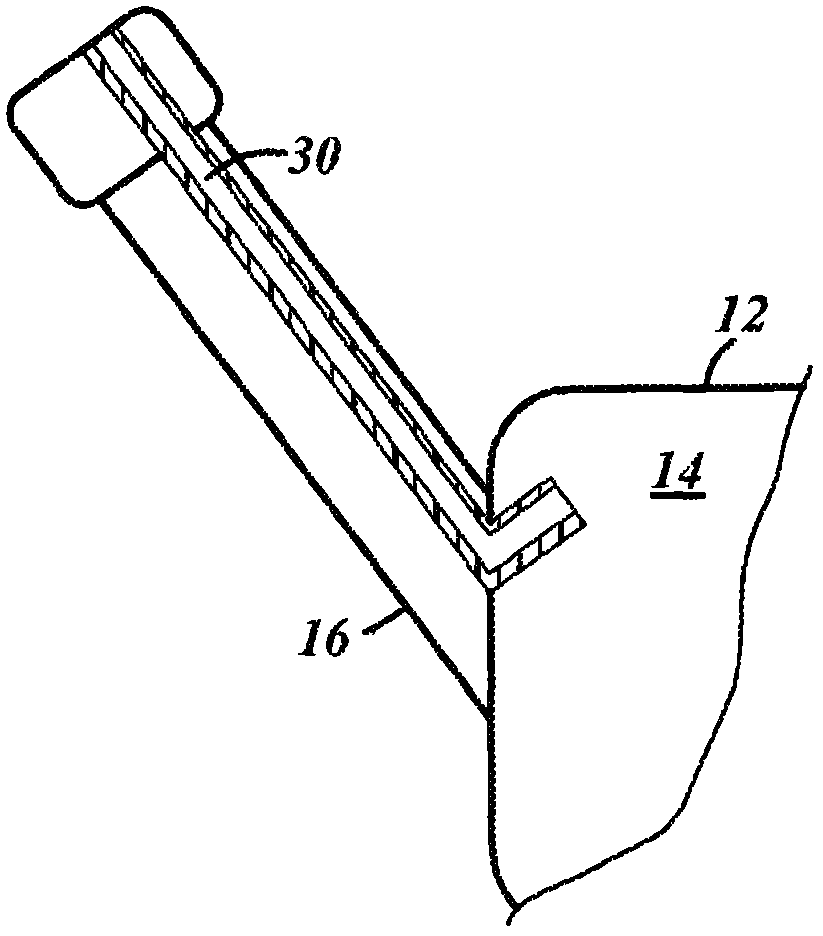

[0013] Referring to the accompanying drawings in more detail, figure 1 Shown is a vehicle fuel tank 10 designed to hold a volume of fuel to support operation of the vehicle engine. Fuel tank 10 may have a tank body 12 defining an interior chamber 14 in which fuel is received, and a fill tube 16 through which fuel is admitted into chamber 14 . If desired, an overpressure relief valve 18 may also be provided which only opens when the pressure in the fuel tank 10 is above a threshold level. A fuel pump 20, which may be located inside the fuel tank 10, or, if desired, external to the fuel tank, may receive fuel from the fuel tank chamber 14 and deliver it under pressure to fuel system components downstream of the fuel tank (e.g., fuel rails). and fuel injectors). Fuel pump 20 may be of conventional construction and arrangement and will not be discussed further. Output from fuel pump 20 may be provided through conduit 22 through fuel tank opening 24, preferably in the same area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com